Milk pudding added with AD calcium and making method thereof

A technology of milk pudding and milk powder, which is applied to the functions of food ingredients, food ingredients as colors, and food ingredients as emulsifiers, etc., which can solve the problems of restricting the marketing of milk pudding products, lack of milk flavor and creaminess, and inability to meet normal temperature storage requirements. Transportation requirements and other issues, to achieve the effect of solving stability and short shelf life, good market response, and improving flavor and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

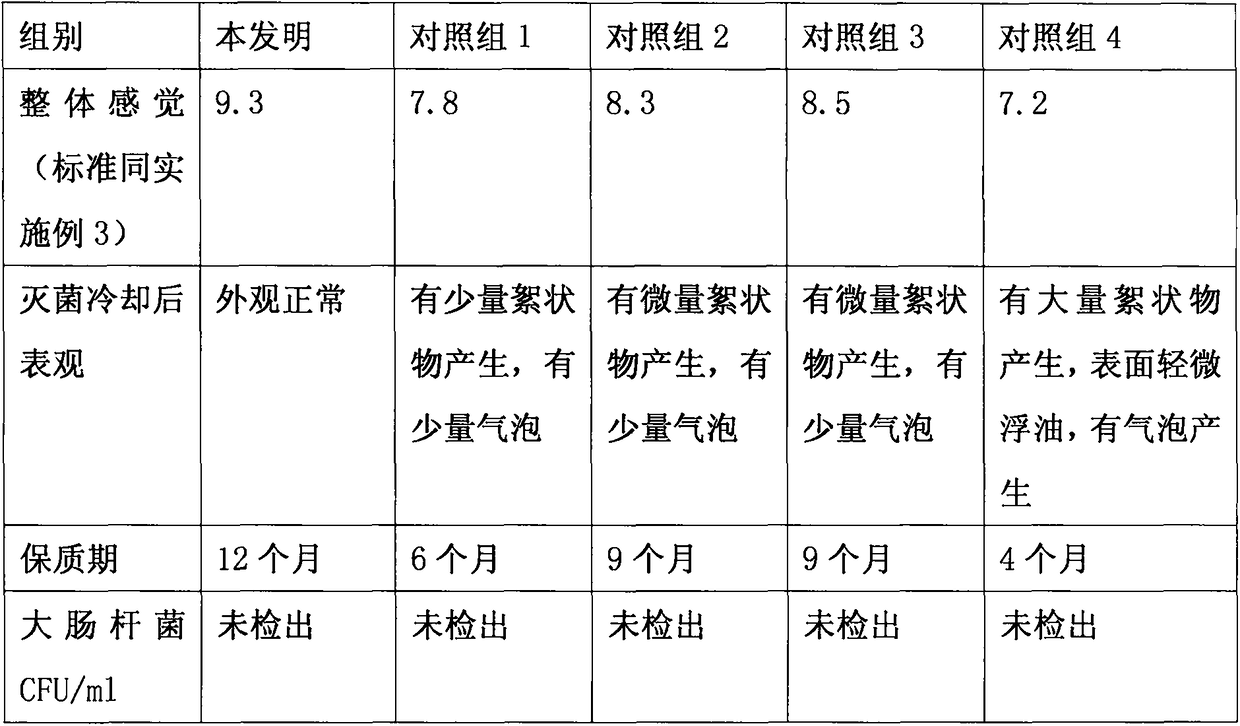

Examples

Embodiment 1

[0025] A milk pudding with AD calcium added, which is prepared from the following raw materials: according to the formula per ton, 43kg of milk powder, 40kg of white sugar, 6kg of emulsifier, 1.5kg of DL-malic acid, 1.5kg of lactic acid, 1kg of honey, β - Carotene 0.5kg, calcium lactate 0.5kg, food grade vitamin A 0.5kg, cholecalciferol (vitamin D3) 0.5kg, Lactobacillus bulgaricus 0.3kg, Streptococcus thermophilus 0.3kg, the rest is drinking purified water;

[0026] The emulsifier is prepared by mixing pectin, sodium carboxymethylcellulose and sodium alginate according to the mass ratio of 1:1:1;

[0027] The preparation method of described milk pudding comprises the steps:

[0028] Preparation of fermented liquid: fully stir 1kg of milk powder (select whole milk powder, protein content is 30wt%) and 8kg of drinking purified water evenly, pump into fermentation tank, heat up to 90°C for sterilization for 15min, then drop to 40°C, then Enter Lactobacillus bulgaricus (1×10 9 i...

Embodiment 2

[0034] A milk pudding with AD calcium added, which is prepared from the following raw materials: according to the formula per ton, 43kg of milk powder, 40kg of white sugar, 6kg of emulsifier, 1.5kg of DL-malic acid, 1.5kg of lactic acid, 1kg of honey, β -Carotene 0.6kg, calcium lactate 0.6kg, food grade vitamin A 0.6kg, cholecalciferol (vitamin D3) 0.6kg, Lactobacillus bulgaricus 0.4kg, Streptococcus thermophilus 0.4kg, the rest is pure drinking water;

[0035] The emulsifier is prepared by mixing pectin, sodium carboxymethylcellulose and sodium alginate according to the mass ratio of 1:1:1;

[0036] The preparation method of described milk pudding comprises the steps:

[0037] Preparation of fermented liquid: fully stir 1kg of milk powder (select whole milk powder, protein content is 30wt%) and 8kg of drinking purified water evenly, pump into fermentation tank, heat up to 90°C for sterilization for 15min, then drop to 40°C, then Enter Lactobacillus bulgaricus (1×10 9 indivi...

Embodiment 3

[0043] Each raw material standard that product of the present invention uses is shown in Table 1:

[0044] Table 1

[0045] raw material name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com