Silkworm flat silk spinning device

A flat silk and flat-plate technology, which is applied in the field of sericulture and silk making, can solve the problems of polluted silk, failure to pupate normally, and reduced silkworm pupation rate, and achieve the effects of reducing labor intensity, saving working time, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

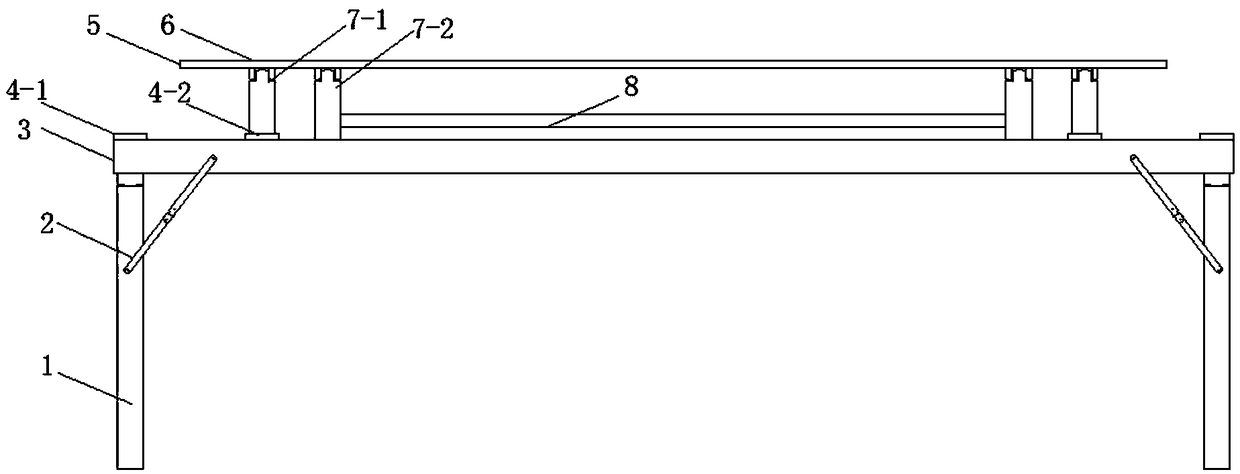

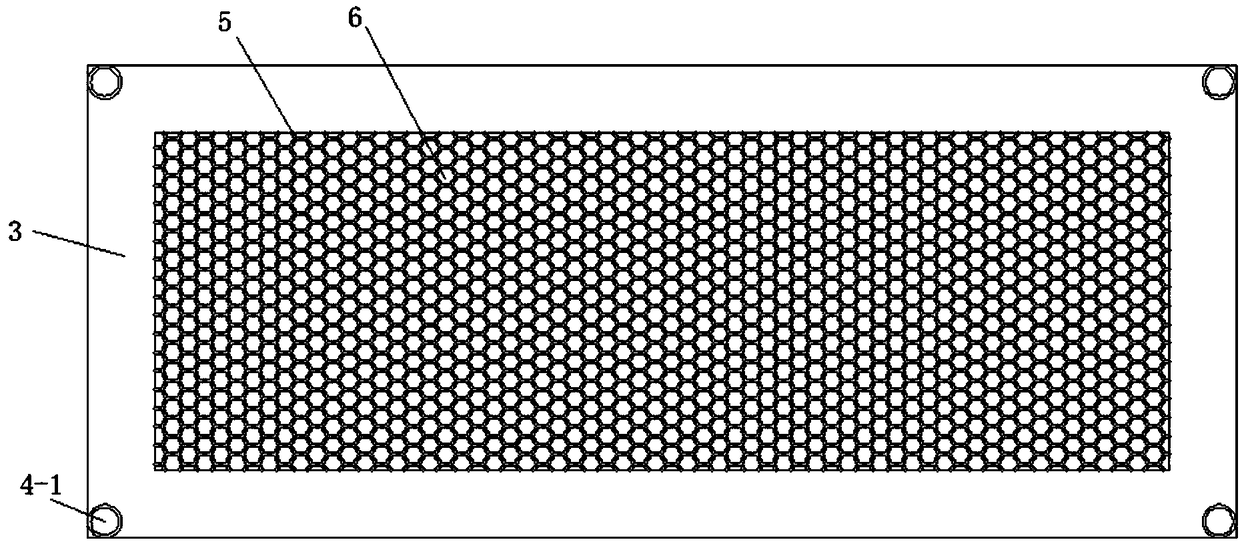

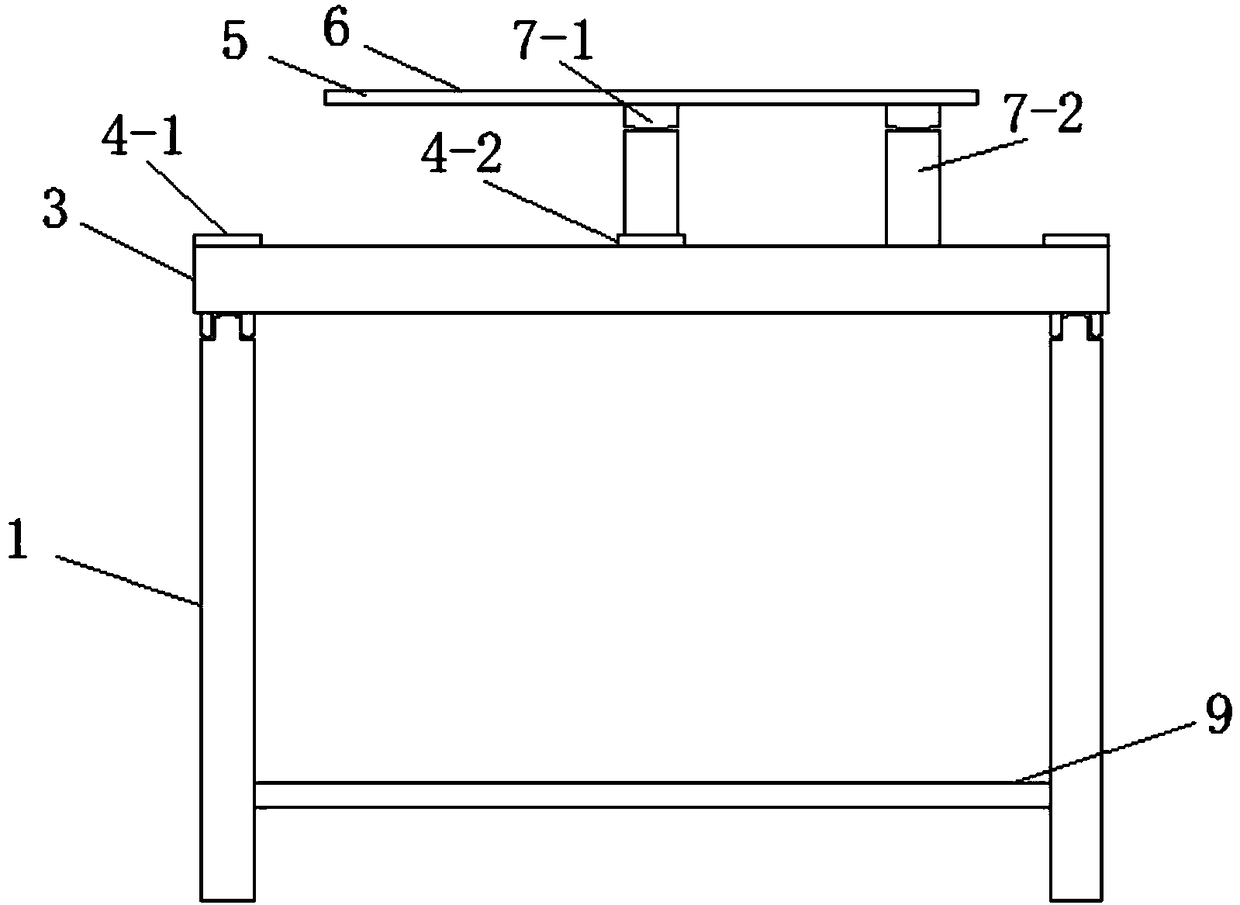

[0026] Such as Figure 1~4 As shown, the silkworm flat silk spinning device of the present invention includes a spinning flat 5, a spinning flat support column 7, a flat support 3 and a flat support support column 1. Spinning flat plate 5 is laid with gauze 6, is used for the attachment of silkworm. The spinneret flat support column 7 is located below the spinneret 5 and is used to support the spinneret 5 . The plate support 3 is used to support the spinning plate support column 7 and the spinning plate 5, and to receive silkworms and silkworm chrysalis. The support columns 1 of the tablet support are located at the four corners below the tablet support 3 and are used to support the tablet support 3 .

[0027] The upper end of the spinning flat plate 5 and the spinning flat support column 7 is hinged through a balance fulcrum, so that the spinning flat plate 5 can be freely inclined. The spinning flat support column 7 on one side of the spinning flat plate 5 is the first su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com