class porous znfe 2 o 4 /c Lithium-ion battery negative electrode material and preparation method thereof

A lithium-ion battery, hierarchical porous technology, applied in the field of electrochemistry, can solve the problems of low carbon conversion efficiency and uneven carbon layer, and achieve the effect of high carbon conversion rate, accelerated electrochemical reaction rate, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

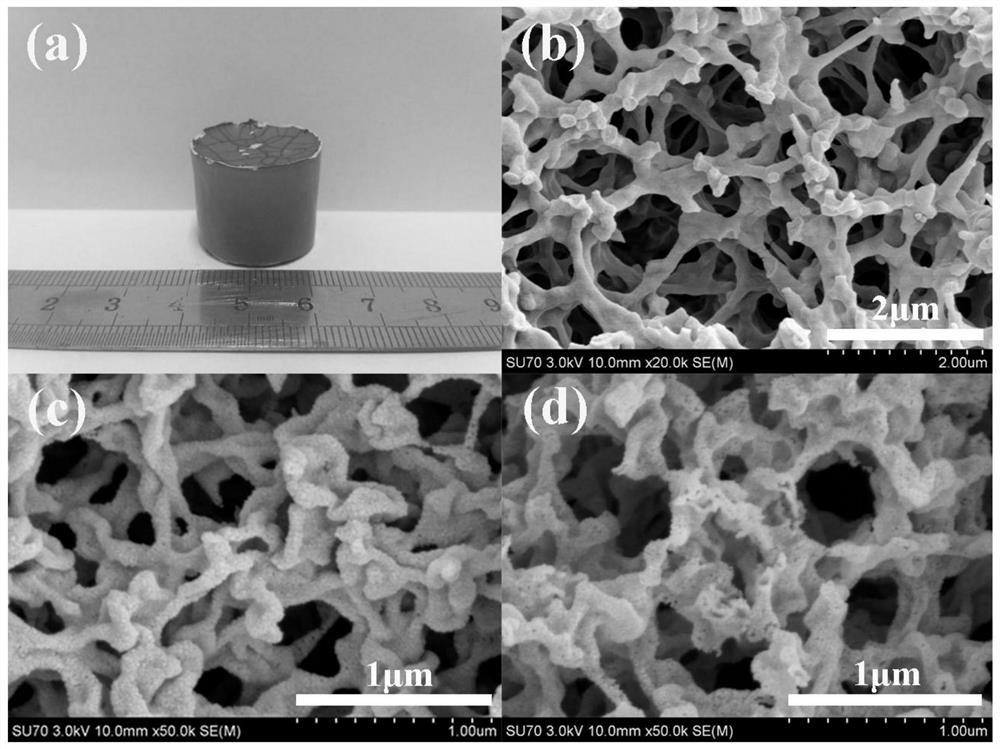

[0066] Example 1-1, Hierarchical Porous ZnFe 2 O 4 / C Lithium Ion Battery Anode Material Preparation Method, including the following steps:

[0067] A), 1.2 ml of deionized water (0.067 mol) was suggested to 2.4 ml of glycerol, and the magnetic force was stirred to mix well, and the solution I was obtained.

[0068] B), 2.5 g of polyacrylic acid is added to the solution I obtained from step a), and the polyacrylic acid has a molecular weight of 10000, thoroughly stirred to polyacrylic acid completely dispersion dissolution, and obtains solution II (uniform solution);

[0069] Note: 1.2ml of deionized water is 1.2g;

[0070] C) Add ZnCl as a precursor to the solution II obtained from step b). 2 (Ie, zinc source) 0.408 g (0.0029 mol) and FECL 2 · 4h 2 O (iron source) 1.192g (0.0058mol), stir until ZnCl 2 FECL 2 · 4h 2 O is completely hydrolyzed to obtain a clear and transparent solution III;

[0071] At this time, deionized water and ZnCl 2 The molar ratio is 23.1: 1 (0.067: 0.0029...

Embodiment 1

[0088] Example 1-2, the temperature of step e, step f, and step j in the oven is changed from 40 ° C to 50 ° C, and the temperature of the drop plus process in step d is changed from no more than 40 ° C In order not to exceed 50 ° C, the rest is equivalent to Example 1.

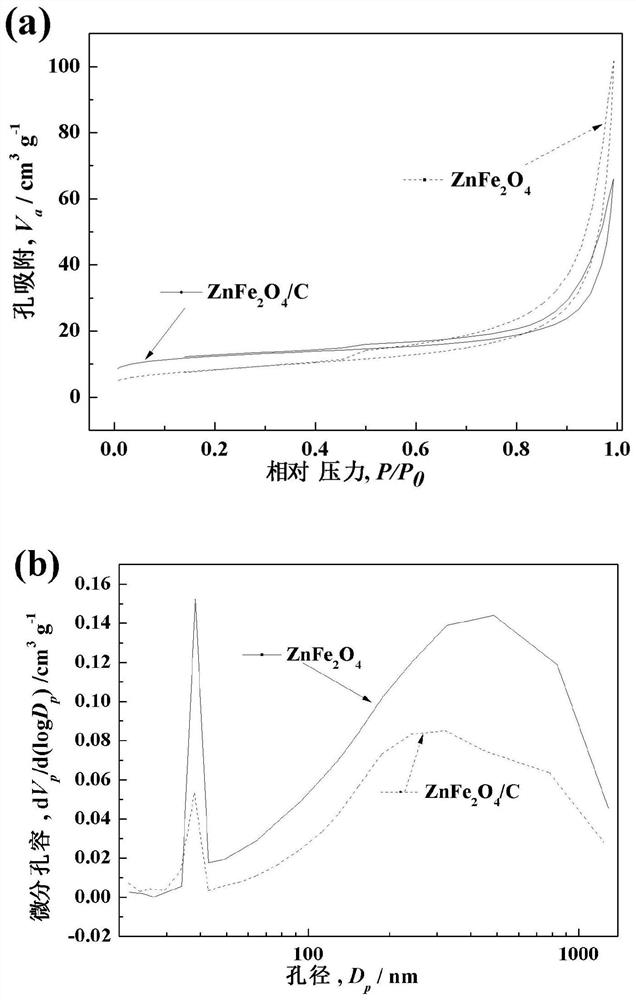

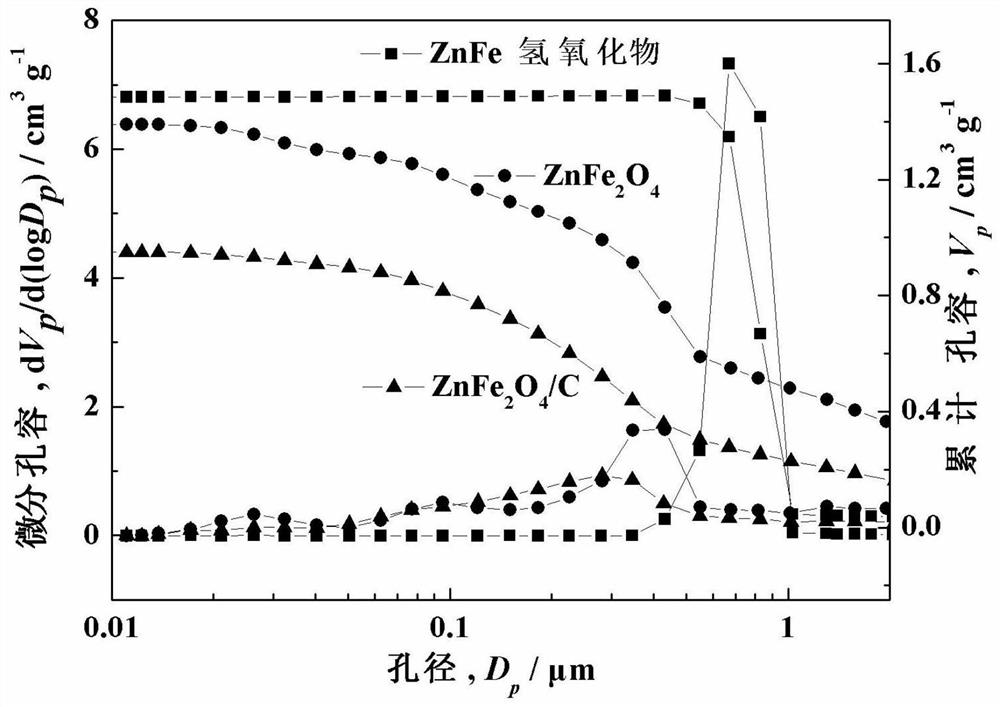

[0089] Znfe 2 O 4 For hollow skeleton structure, its large pore size is 420 nm, Znfe 2 O 4 / C Macroporous size is 350 nm; ZnFe2O4 mesh is 35 nm, and the ZnFe2O4 / C mesh is 32 nm;

[0090] Znfe 2 O 4 The / C carbon layer has a uniform 4 nm, and the load capacity of carbon is 9.2%, and the conversion of carbon is 55.2%. At the current density of 200mAg -1 The performance of the charge and discharge cycle, the discharge ratio capacitance 860mAh g after 100 turns of the current density charge cycle -1 . In the current density of 1AG -1 The performance of the charge and discharge cycle, the discharge ratio capacitor can retain 670mAh g after the electricity density is 400 laps -1 .

[0091] Znfe 2 O 4 / C, znfe 2 O ...

Embodiment 2

[0102] Example 2, ZnFe is prepared in Example 1-1 2 O 4 Method Change to the following steps:

[0103] A), 1 mL (0.056 mol) of deionized water was added to 2 mL of glycerol, and the magnetic force was stirred to mix well, and the solution I was obtained.

[0104] B), 2.5 g of polyacrylic acid is added to the solution I obtained from step a), and the polyacrylic acid has a molecular weight of 100,000, stirred until the polyacrylic acid is completely dispersed, and the solution II (uniform solution) is obtained;

[0105] C), add Zn as a precursor to the solution II obtained from step b) (NO 3 ) 2 · 6h 2 O 0.826g (0.00278mol) and Fe (NO 3 ) 2 · 6h 2 O 1.60g (0.00556mol), stir until Zn (no 3 ) 2 · 6h 2 O and Fe (NO 3 ) 2 · 6h 2 O is completely hydrolyzed to obtain a clear and transparent solution III;

[0106] At this time, deionized water and ZnCl 2 The molar ratio is 20.1: 1 (0.056: 0.00278);

[0107] Zn (NO) 3 ) 2 · 6h 2 O and Fe (no 3 ) 2· 6h 2 O The molar ratio is 1: 2;

[0108] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com