Textile defect detecting device

A detection device and textile technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of unable to adjust the tension of the gray cloth, wrinkles on the surface of the gray cloth, and affecting the quality of the finished product, so that it is not easy to loosen, improve the flatness, The effect of high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

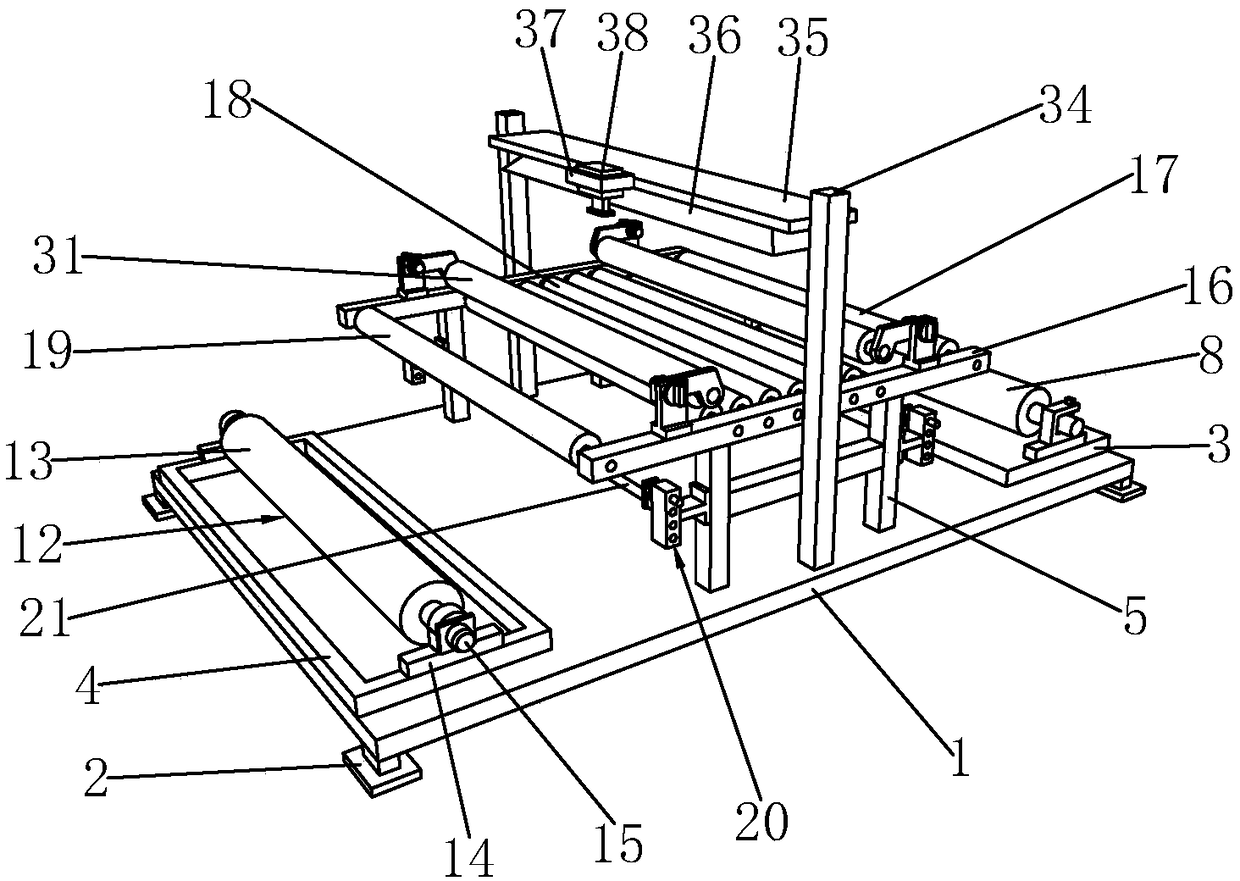

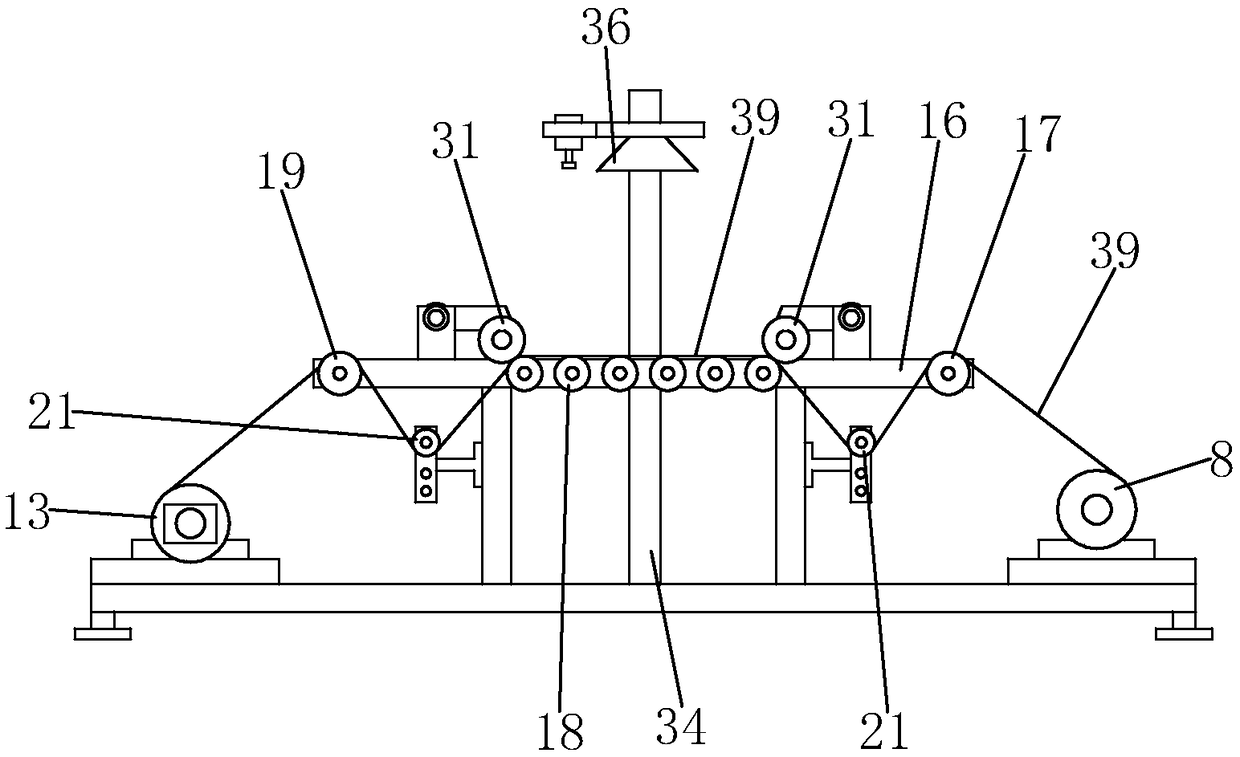

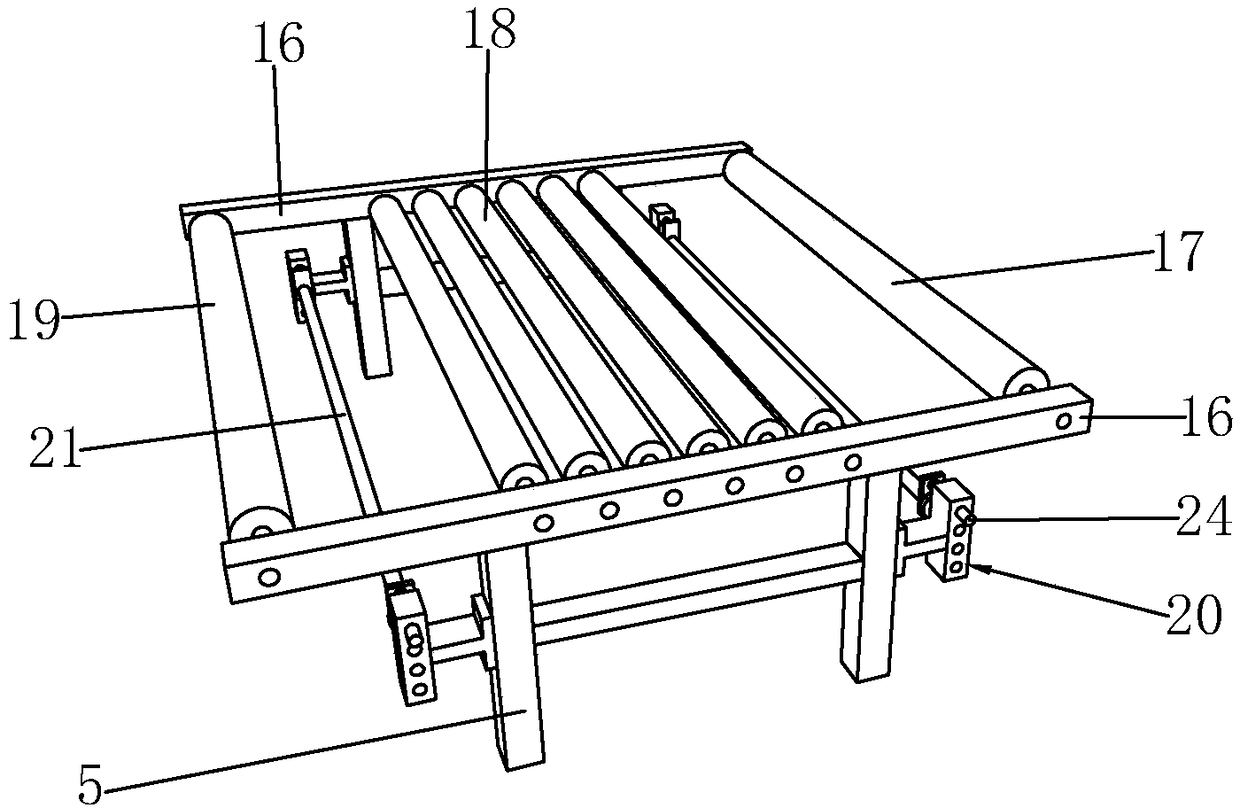

[0029] Such as Figure 1 to Figure 7 As shown, it is a textile defect detection device of the present invention, which includes a working platform 1 and supporting feet 2. The supporting feet 2 are arranged on the four corners of the bottom surface of the working platform 1, and the working platform 1 is respectively provided with a support plate 3 and a fixing frame 4. And the support frame 5, the support frame 5 is located between the support plate 3 and the fixed frame 4, the support plate 3 is provided with a cloth release mechanism 6, the cloth release mechanism 6 includes a deck 7 and a cloth release roller 8, and the cloth release roller 8 is clamped Between the card seats 7, the card seats 7 are arranged on the support plate 3, and the cloth releasing roller 8 and the card seats 7 adopt a detachable connection mode, which is convenient for installation and replacement of gray cloth, and the connection is reliable, simple and practical. The deck 7 is provided with a U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com