Formula of pulp for producing paper straws

A pulp and straw technology, applied in natural cellulose pulp/paper, paper, papermaking and other directions, can solve the problems of unsatisfactory paper straw production technology, low strength of paper straws, affecting use, etc., to improve the utilization rate, dry High tensile strength and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

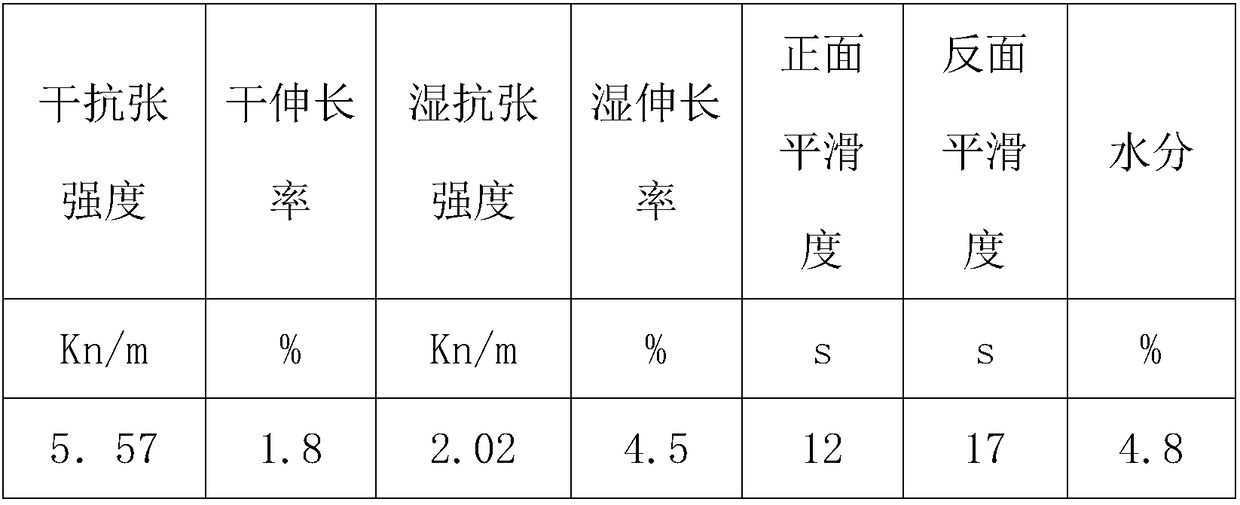

Embodiment 1

[0016] Embodiment 1: A formula for producing pulp for paper straws, which is formed by mixing softwood pulp, hardwood pulp, recycled paper pulp and additives.

[0017] Additives include wet strength agents and sizing agents.

[0018] The additives also include defoamers, and the addition ratio is 0.5% of the total mass.

[0019] The ratio of softwood pulp, hardwood pulp and recycled paper pulp is 20:50:10.

[0020] wet strength agent wet strength agent Polyamide The polyepichlorohydrin resin is prepared, and the addition ratio is 3% of the total mass, and the sizing agent is alkyl ketene dimer, and the addition ratio is 2% of the total mass.

[0021] Wet strength agent consists of 10% of Polyamide The polyepichlorohydrin resin is mixed with 90% water, the stirring time is 10 minutes, and the stirring speed is 100rmp.

[0022] The softwood pulp is disintegrated by a pulper for 10 minutes, and the beating degree is 70°SR.

[0023] The hardwood pulp is disintegrated by a pul...

Embodiment 2

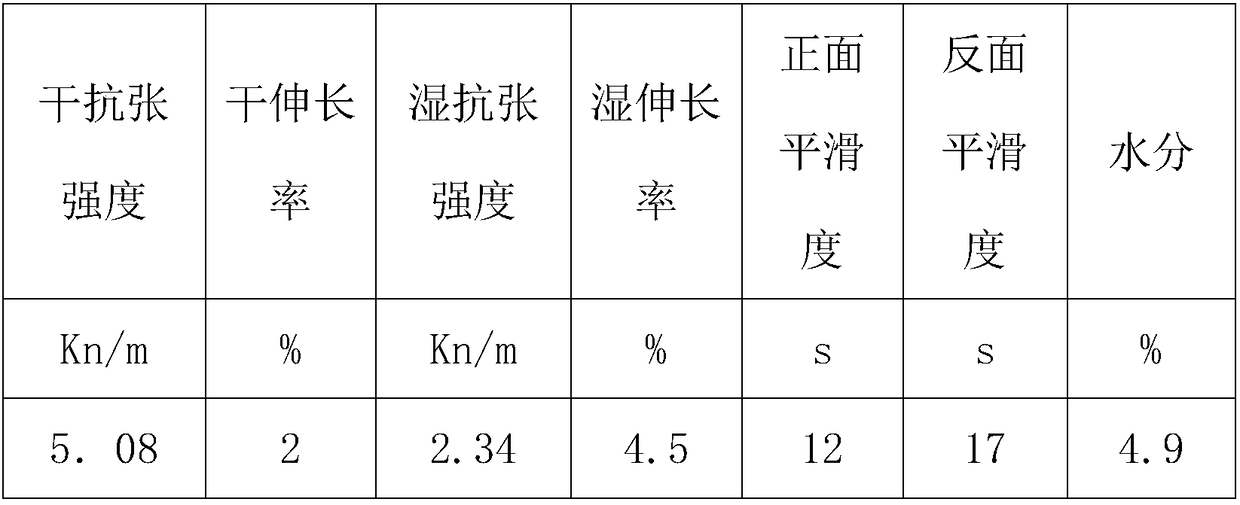

[0028] Embodiment 2: A formula for producing pulp for paper straws, which is formed by mixing softwood pulp, hardwood pulp, recycled paper pulp and additives.

[0029] Additives include wet strength agents and sizing agents.

[0030] The additives also include defoamers, and the addition ratio is 0.5% of the total mass.

[0031] The ratio of softwood pulp, hardwood pulp and recycled paper pulp is 40:80:20.

[0032] wet strength agent wet strength agent Polyamide The polyepichlorohydrin resin is prepared, and the addition ratio is 3% of the total mass, and the sizing agent is alkyl ketene dimer, and the addition ratio is 2% of the total mass.

[0033] Wet strength agent consists of 30% of Polyamide The polyepichlorohydrin resin is mixed with 70% water, the stirring time is 10 minutes, and the stirring speed is 100rmp.

[0034] The softwood pulp is disintegrated by a pulper for 5 minutes, and the beating is circulated, and the beating degree is 50°SR.

[0035] The hardwood ...

Embodiment 3

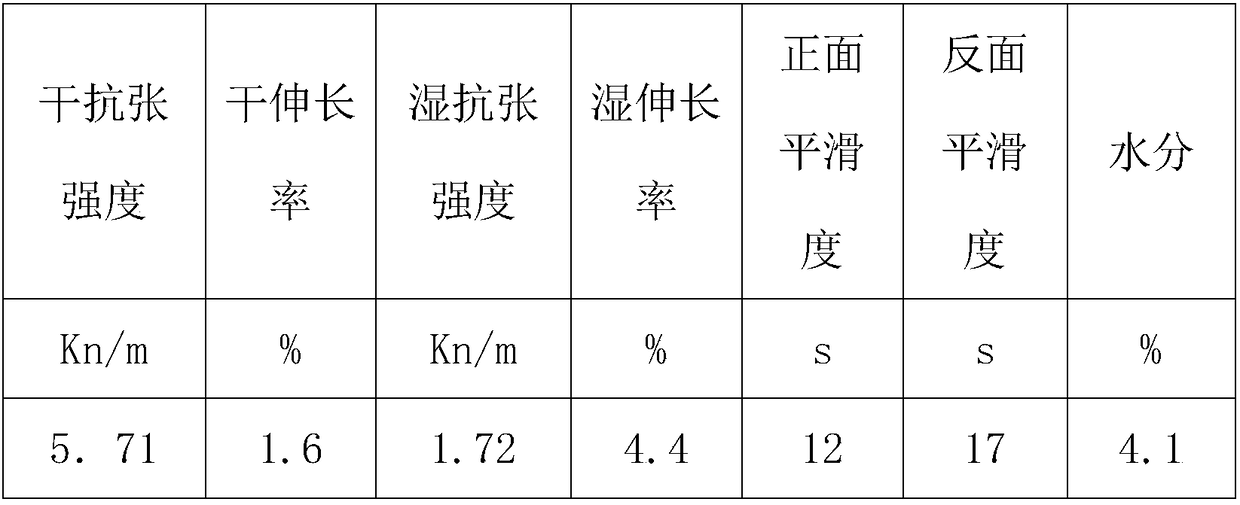

[0040] Embodiment 3: A formula for producing pulp for paper straws, which is formed by mixing softwood pulp, hardwood pulp, recycled paper pulp and additives.

[0041] Additives include wet strength agents and sizing agents.

[0042] The additives also include defoamers, and the addition ratio is 0.5% of the total mass.

[0043] The ratio of softwood pulp, hardwood pulp and recycled paper pulp is 40:80:20.

[0044] wet strength agent wet strength agent Polyamide The polyepichlorohydrin resin is prepared, and the addition ratio is 3% of the total mass, and the sizing agent is alkylketene dimer, and the addition ratio is 3% of the total mass.

[0045] Wet strength agent consists of 25% of Polyamide The polyepichlorohydrin resin is mixed with 75% water, the stirring time is 10 minutes, and the stirring speed is 150rmp.

[0046] The softwood pulp is disintegrated by a pulper for 8 minutes, and the beating is circulated, and the beating degree is 65°SR.

[0047] The hardwood p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com