Composite wool fabric with good drapability and preparation method thereof

A composite fabric and drape technology, applied in the field of clothing fabrics, can solve the problems of poor fabric softness, easy wrinkling and looping, no layering, etc., to improve hygroscopicity and softness, promote loosening, and reduce crystallization. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

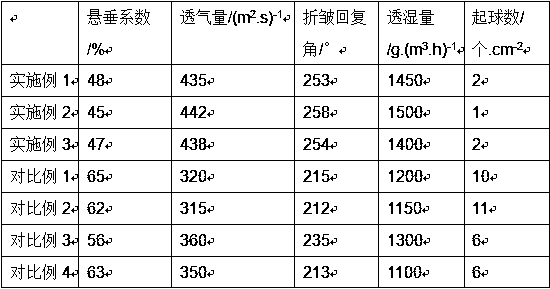

Examples

Example Embodiment

[0023] Example 1

[0024] A wool composite fabric with good drapability has the following components by weight: 20 parts of wool fiber, 2 parts of sodium lauryl sulfate, 10 parts of 15% dilute hydrochloric acid, 30 parts of 40% calcium chloride solution, silk 5 parts of cellulose, 3 parts of azobisisobutyronitrile, 5 parts of acrylonitrile, 3 parts of dicumyl peroxide, 2 parts of zinc oxide, 5 parts of modal fiber, 6 parts of Angora rabbit hair fiber, 2 parts of cerium ammonium nitrate, 4 parts of modified silicone softener.

[0025] As preferably, the preparation method of the modified silicone softener is as follows:

[0026] 1) Take 5 parts of ethylene glycol and 4 parts of terephthalic acid, mix them to make a slurry, stir them evenly and add them to the reaction kettle, then add 1 part of catalyst antimony trioxide, heat to 230°C, and react for 4 hours. Then lower the temperature to 100°C, add 3 parts of 2-hydroxyphosphoacetic acid and 2 parts of ethyl acetate, and cont...

Example Embodiment

[0037] Example 2

[0038] A wool composite fabric with good drapability has the following components by weight: 25 parts of wool fiber, 2 parts of sodium lauryl sulfate, 12 parts of 17% dilute hydrochloric acid, 35 parts of 45% calcium chloride solution, silk 7 parts of plain element, 4 parts of azobisisobutyronitrile, 7 parts of acrylonitrile, 3 parts of dicumyl peroxide, 2 parts of zinc oxide, 7 parts of modal fiber, 7 parts of Angora rabbit hair fiber, 2 parts of cerium ammonium nitrate, 5 parts of modified silicone softener.

[0039] As preferably, the preparation method of the modified silicone softener is as follows:

[0040] 1) Take 7 parts of ethylene glycol and 5 parts of terephthalic acid, mix them to make a slurry, stir them evenly and add them to the reaction kettle, then add 1 part of catalyst antimony trioxide, heat to 260°C, and react for 3.5 hours , then lower the temperature to 110°C, add 3 parts of 2-hydroxyphosphoacetic acid and 2 parts of ethyl acetate, a...

Example Embodiment

[0051] Example 3

[0052] A wool composite fabric with good drapability has the following components by weight: 30 parts of wool fiber, 3 parts of sodium lauryl sulfate, 15 parts of 20% dilute hydrochloric acid, 40 parts of 50% calcium chloride solution, silk 8 parts of plain element, 5 parts of azobisisobutyronitrile, 10 parts of acrylonitrile, 4 parts of dicumyl peroxide, 3 parts of zinc oxide, 10 parts of modal fiber, 8 parts of Angora rabbit hair fiber, 3 parts of ammonium cerium nitrate, 6 parts of modified silicone softener.

[0053] As preferably, the preparation method of the modified silicone softener is as follows:

[0054] 1) Take 10 parts of ethylene glycol and 7 parts of terephthalic acid, mix them to make a slurry, stir them evenly and add them to the reaction kettle, then add 2 parts of antimony trioxide as a catalyst, heat to 280°C, and react for 3 hours. Then lower the temperature to 120°C, add 4 parts of 2-hydroxyphosphoacetic acid and 3 parts of ethyl acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com