Preparation method of fluorescent nanofiber film based on acrylic based emulsion

A technology of fluorescent nanofibers and acrylic latex, which is applied in the field of preparation of fluorescent nanofiber membranes, can solve the problems of human and aquatic biological hazards, quenching of fluorescent probes, environmental pollution, etc. Effect of Fluorescence Intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

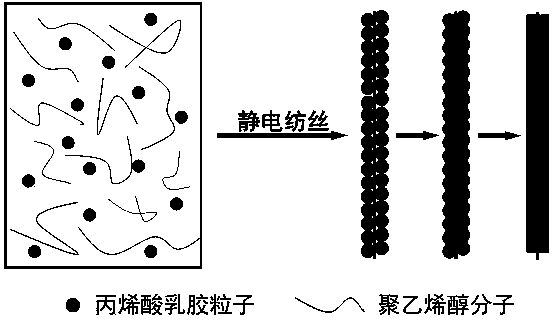

Method used

Image

Examples

Embodiment 1

[0030] A fluorescent nanofiber film, comprising rhodamine B modified acrylic resin, the mass ratio between rhodamine B and acrylic resin in the rhodamine B modified acrylic resin is 1:100, and its preparation method for:

[0031] A. Preparation of rhodamine B modified fluorescent acrylic composite latex

[0032] Rhodamine B and acrylic acid monomers are used under the action of emulsifiers to prepare fluorescent acrylic latex based on rhodamine B modification by means of emulsion polymerization:

[0033] Rhodamine B was mixed with acrylic acid monomer in a mass ratio of 1:100, and the acrylic acid monomer was composed of 35 wt% methyl methacrylate, 60 wt% isooctyl acrylate and 5 wt% methacrylic acid. Obtain solution A, dissolve the emulsifier sodium lauryl sulfate relative to the solution A quality 1wt% and the initiator ammonium persulfate relative to the solution A quality 1wt% in deionized water equal to the quality of solution A, obtain the solution B. Stir and mix evenl...

Embodiment 2

[0040] A fluorescent nanofiber film, comprising rhodamine B modified acrylic resin, the mass ratio between rhodamine B and acrylic resin in the rhodamine B modified acrylic resin is 1:400, and its preparation method for:

[0041] A. Preparation of rhodamine B modified fluorescent acrylic composite latex

[0042] Rhodamine B and acrylic acid monomers are used under the action of emulsifiers to prepare fluorescent acrylic latex based on rhodamine B modification by means of emulsion polymerization:

[0043]Rhodamine B was mixed with acrylic acid monomer at a mass ratio of 1:400, and the acrylic acid monomer was composed of 55 wt% methyl methacrylate, 40 wt% isooctyl acrylate and 5 wt% methacrylic acid. Obtain solution A, be dissolved in the deionized water with solution A equal quality with respect to the emulsifier sodium lauryl sulfate of solution A quality 2wt% and the initiator ammonium persulfate relative to solution A quality 0.5wt% simultaneously, obtain Solution B, stir...

Embodiment 3

[0049] A fluorescent nanofiber film, comprising rhodamine B modified acrylic resin, the mass ratio between rhodamine B and acrylic resin in the rhodamine B modified acrylic resin is 1:800, and its preparation method for:

[0050] A. Preparation of rhodamine B modified fluorescent acrylic composite latex

[0051] Rhodamine B and acrylic acid monomers are used under the action of emulsifiers to prepare fluorescent acrylic latex based on rhodamine B modification by means of emulsion polymerization:

[0052] Rhodamine B was mixed with acrylic acid monomer at a mass ratio of 1:800, and the acrylic acid monomer was composed of 45 wt% methyl methacrylate, 54 wt% isooctyl acrylate and 1 wt% methacrylic acid. Obtain solution A, simultaneously with the emulsifier sodium lauryl sulfate of 4wt% relative to solution A quality and the initiator ammonium persulfate relative to solution A quality 0.3wt% be dissolved in the deionized water with solution A equal quality, obtain Solution B, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com