Composite microbial agent and application thereof in tobacco stems

A technology of compound microbial bacterial agent and bacterial agent, which is applied in the field of patent application matters to achieve the effect of improving the quality of tobacco stems, low processing cost, and good promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The composite microbial bacterial agent provided in this application is specifically prepared through the following steps.

[0044] (1) Preparation of Bacillus subtilis XC-19-1 active bacterial agent

[0045] Place the Bacillus subtilis XC-19-1 strain on the LB plate, activate and cultivate it at 37°C for 72 hours, collect the cultured colonies, inoculate them in liquid LB medium, and cultivate them overnight on a shaker at 37°C as the seed solution;

[0046] The seed solution was transferred to liquid LB medium at a volume ratio of 1%, and cultivated to OD at 30°C and 150 rpm. 600 =2.0 or so as fermentation broth;

[0047] Centrifuge the fermentation broth at 3600 rpm for 10min, discard the supernatant, then add sterile water to fully suspend, and adjust the number of viable bacteria to 11×10 7 A / mL spare.

[0048] (2) Preparation of Bacillus pumilus SMXP-3 active bacterial agent

[0049] Put the Bacillus pumilus SMXP-3 strain on the LB plate, and after 72 hours of...

Embodiment 2

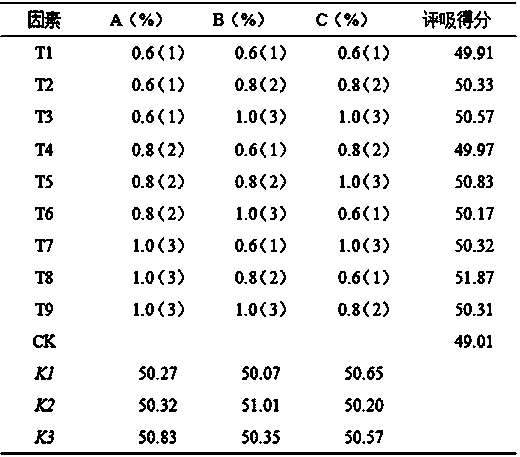

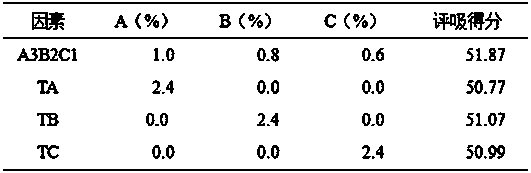

[0059] When using the composite microbial agent prepared in Example 1 to treat tobacco stems, in order to determine the optimal ratio of the composite microbial agent and its specific effect on tobacco stems, the inventor carried out partial orthogonal experiment optimization. The specific process is as follows: :

[0060] According to the single dosage ratio of each active bacterial agent in the tobacco stem, the three kinds of bacterial solutions were absorbed and mixed. After adjusting the number of viable bacteria, the mixed bacterial solution was evenly applied to the cut stems (100 g of cut stems for each treatment), and at the same time Set up a blank control group and three kinds of single-bacteria liquid treatment groups, then adjust the moisture content of cut stems in each experimental group to 25%, place them in a constant temperature and humidity chamber (control temperature at 37°C, and humidity at 75%), and take them out after 96 hours of fermentation , placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com