Photochromic polyurethane composite with ultraviolet-resistant function

A technology of anti-ultraviolet and composite materials, applied in the field of polymer materials, can solve the problems of no anti-ultraviolet and single color of polyurethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of described polymethyl methacrylate modified photochromic agent, comprises the following steps:

[0032] 1) Add methyl methacrylate monomer and ethanol in the reactor, make described methyl methacrylate completely dissolve in ethanol after stirring, add inorganic photochromic agent and organic photochromic agent, continue stirring and Raise the temperature to 60°C-80°C, then add the initiator BPO ethanol solution, stop heating and keep stirring for 1-2 hours, and gradually cool into a solid;

[0033] 2) Grinding the above solid into powder to obtain a polymethyl methacrylate modified photochromic agent.

[0034] Polymethyl methacrylate modified photochromic agent is a core-shell structure with the photochromic agent as the core covering the shell of polymethyl methacrylate. The shell-core structure can ensure a stable combination with polymer materials , and evenly distributed.

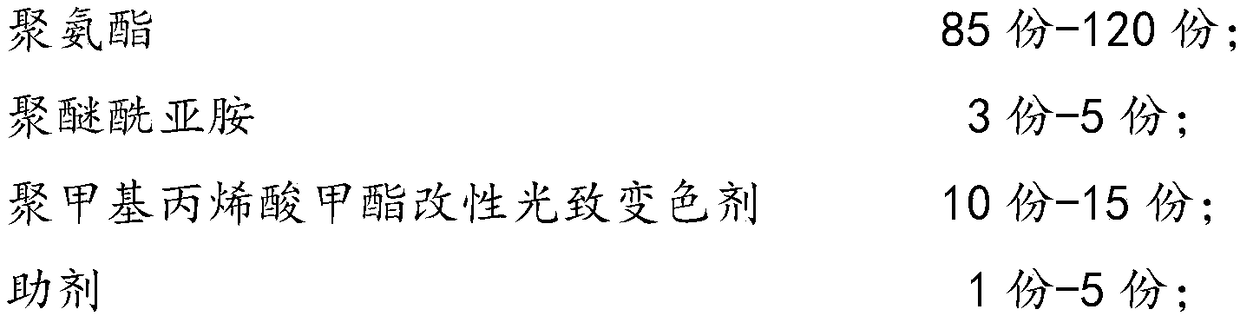

Embodiment 1

[0036] A photochromic polyurethane composite material, which consists of:

[0037]

[0038] The inorganic photochromic agent among them is CaHfO3: La 2 o 3 .

[0039] In the polymethyl methacrylate modified photochromic agent, the photochromic agent accounts for 0.1% of the total weight of the polymethyl methacrylate modified photochromic agent.

[0040] The organic photochromic agent is a combination of spiropyran and azobenzene, wherein the mass ratio of spiropyran and azobenzene is 1:1.

[0041] The auxiliary agent includes one or more combinations of oxidizing agent, compatibilizer, antiaging agent and light stabilizer.

[0042] The preparation method of described polymethyl methacrylate modified photochromic agent, comprises the following steps:

[0043] 1) Add methyl methacrylate monomer and ethanol in the reactor, make described methyl methacrylate dissolve in ethanol completely after stirring, add inorganic photochromic agent and organic photochromic agent, cont...

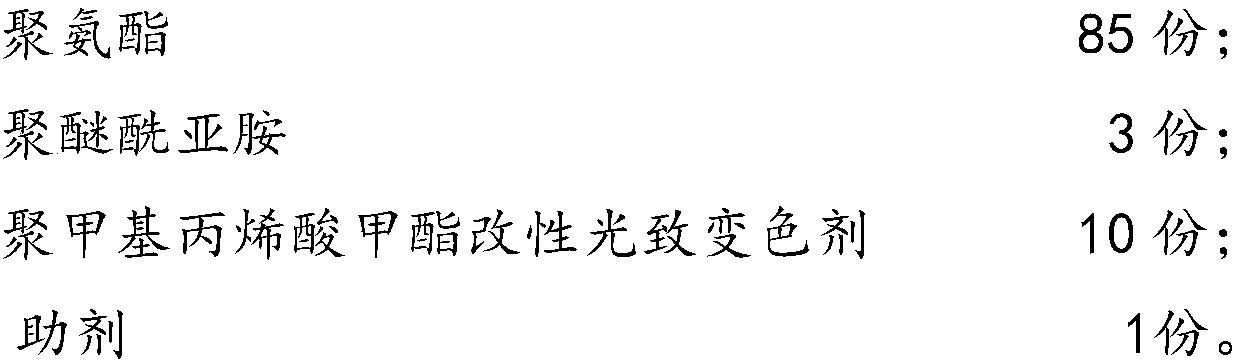

Embodiment 2

[0047] A photochromic polyurethane composite material, which consists of:

[0048]

[0049] The inorganic photochromic agent among them is CaHfO3: La 2 o 3 .

[0050] In the polymethyl methacrylate modified photochromic agent, the photochromic agent accounts for 5% of the total weight of the polymethyl methacrylate modified photochromic agent.

[0051] The organic photochromic agent is a combination of spiropyran and azobenzene, wherein the mass ratio of spiropyran and azobenzene is 1:1.

[0052] The auxiliary agent includes one or more combinations of oxidizing agent, compatibilizer, antiaging agent and light stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com