High-barrier biodegradable mulching film and preparation method thereof

A biodegradable, high-barrier technology, applied in botany equipment and methods, plant protection, plant protection covers, etc., can solve the problems of unfavorable promotion and application, high cost of mulch film, etc., and achieve good barrier performance and biodegradability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

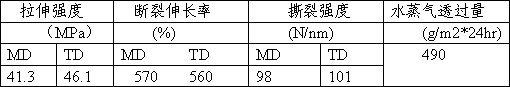

Embodiment 1

[0030] The thickness of the high-barrier biodegradable mulch film in this embodiment is 15 μm.

[0031] The high-barrier biodegradable mulch film in this embodiment consists of the following components by weight: 35 parts of polypropylene carbonate; 44 parts of linear low-density polyethylene; 2.1 parts of 2,4-dihydroxybenzophenone; 2.5 parts of four-carbon alcohol ester; 33 parts of poly-3-hydroxybutyrate-co-3-hydroxyhexanoate; 50 parts of butylene terephthalate; 27 parts of polybutylene succinate; glycidyl acrylate 5.6 parts of ester-grafted polyethylene; 1.3 parts of hindered amine light stabilizer; 0.9 part of isooctyl dimethyl tin dithioacetate; 28 parts of filler; 0.2 part of crosslinking agent.

[0032] The preparation method of the high-barrier biodegradable mulch film in this embodiment includes the following steps: Step 1, adding a crosslinking agent into the filler, stirring continuously for 30 minutes before use;

[0033] Step 2, place polypropylene carbonate at a...

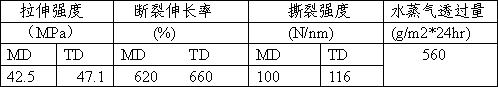

Embodiment 2

[0043] The thickness of the high-barrier biodegradable mulch film in this embodiment is 15 μm.

[0044] The high-barrier biodegradable mulch film in this embodiment consists of the following components in parts by weight: 45 parts of polypropylene carbonate; 60 parts of linear low-density polyethylene; 2.7 parts of 2,4-dihydroxybenzophenone; 2.1 parts of four-carbon alcohol ester; 49 parts of poly-3-hydroxybutyrate-co-3-hydroxyhexanoate; 45 parts of butylene terephthalate; 28 parts of polybutylene succinate; glycidyl acrylate 7.2 parts of ester-grafted polyethylene; 0.8 parts of hindered amine light stabilizer; 1.1 parts of isooctyl dimethyl tin dithioacetate; 28 parts of filler; 0.5 part of crosslinking agent.

[0045] The preparation method of the high-barrier biodegradable mulch film in this embodiment includes the following steps: Step 1, adding a crosslinking agent into the filler, stirring continuously for 30 minutes before use;

[0046] Step 2, place polypropylene carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com