Hyperbranched high-strength energetic compound

A technology of hyperbranched polymers and composites, applied in the field of hyperbranched high-strength energetic composites, can solve problems such as weak mechanical strength, achieve the effect of enhancing interface interaction and improving interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

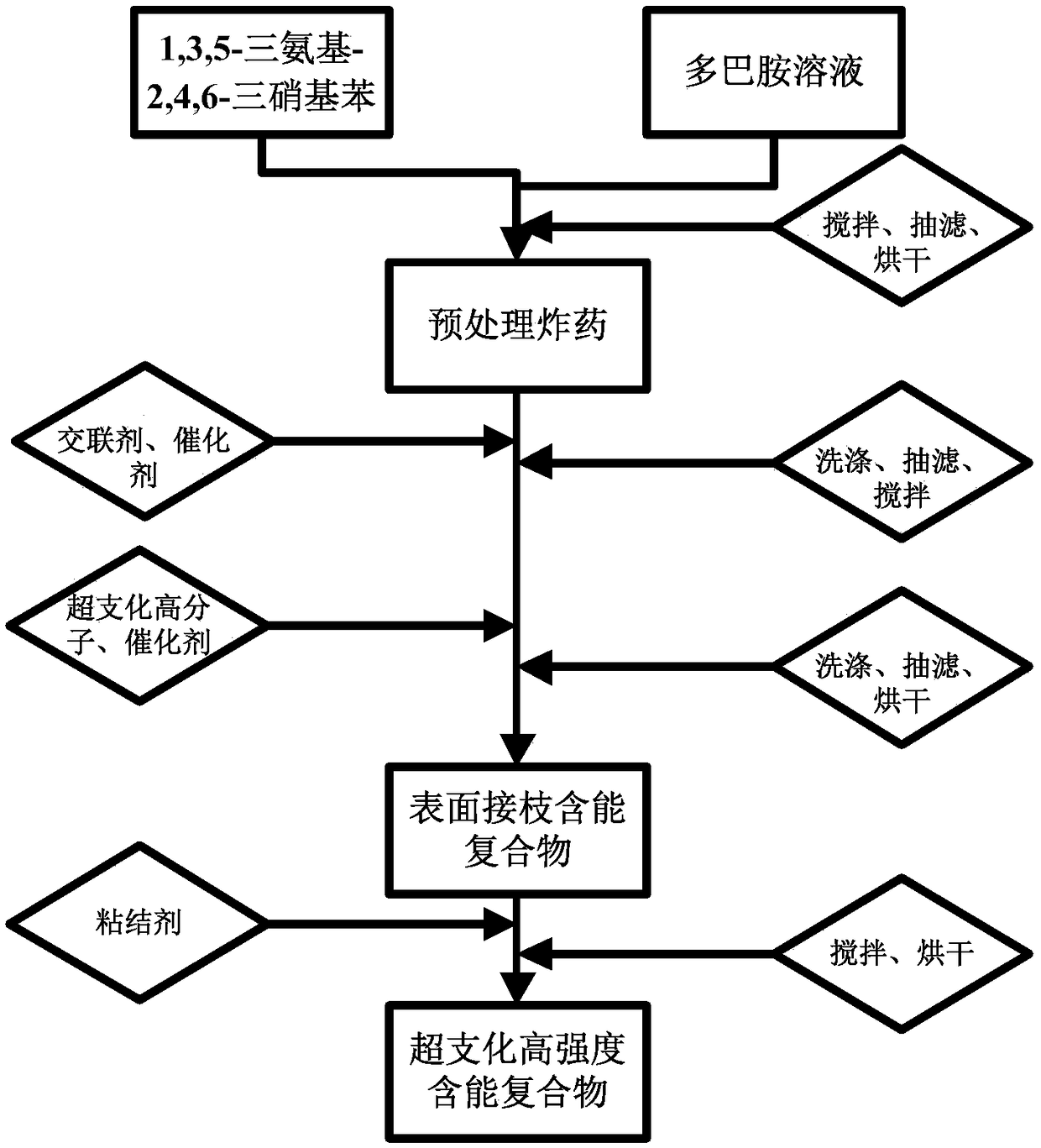

[0030] as attached figure 1 As shown, the specific steps are as follows:

[0031] Step 1: Use hydrochloric acid to adjust the pH value of 1L buffered aqueous solution to 8.5, add 1g of dopamine hydrochloride, and add 100g of energetic crystal 1,3,5-triamino-2,4,6-trinitrobenzene, using 450rpm After mechanical stirring at a rotating speed for 6 hours, suction filtration, washing, and drying were performed to obtain pretreated explosives;

[0032] Step 2: Vacuum the above explosive at 80°C for 30 minutes, add it to 500 g of butyl acetate, ultrasonicate for 1 min to form a suspension, add 0.4 g of toluene diisocyanate and 0.2 g of dibutyltin dilaurate, stir mechanically for 1 h, filter, and wash with acetic acid Butyl ester was washed 4 times, and the whole process was carried out under the condition of 60°C water bath and 400rpm; then the explosive was moved to 500g of acetone, 0.4g of aliphatic hyperbranched polyester H204 and 0.2g of dibutyltin dilaurate were added, and mecha...

Embodiment 2

[0036] Step 1: Use hydrochloric acid to adjust the pH value of 1L buffered aqueous solution to 8.5, add 1g of dopamine hydrochloride, and add 100g of energetic crystal 1,3,5-triamino-2,4,6-trinitrobenzene, using 450rpm After mechanical stirring at a rotating speed for 6 hours, suction filtration, washing, and drying were performed to obtain pretreated explosives;

[0037]Step 2: Vacuum the above explosive at 80°C for 30 minutes, add it to 500 g of butyl acetate, ultrasonicate for 1 minute to form a suspension, add 0.6 g of toluene diisocyanate and 0.3 g of dibutyltin dilaurate, stir mechanically for 1 hour, filter, and wash with acetic acid Butyl ester was washed 4 times, and the whole process was carried out under the conditions of 60°C water bath and 400rpm rotation speed; then the explosive was moved to 500g of acetone, 0.6g of aliphatic hyperbranched polyester H204 and 0.3g of dibutyltin dilaurate were added, and mechanically stirred for 1h , filtered, washed with acetone ...

Embodiment 3

[0041] Step 1: Use hydrochloric acid to adjust the pH value of 1L buffered aqueous solution to 8.5, add 1g of dopamine hydrochloride, and add 100g of energetic crystal 1,3,5-triamino-2,4,6-trinitrobenzene, using 450rpm After mechanical stirring at a rotating speed for 6 hours, suction filtration, washing, and drying were performed to obtain pretreated explosives;

[0042] Step 2: Vacuum the above explosive at 80°C for 30 minutes, add it to 500 g of butyl acetate, ultrasonicate for 1 minute to form a suspension, add 0.6 g of toluene diisocyanate and 0.3 g of dibutyltin dilaurate, stir mechanically for 1 hour, filter, and wash with acetic acid Butyl ester was washed 4 times, and the whole process was carried out under the conditions of 60°C water bath and 400rpm rotation speed; then the explosive was moved to 500g of acetone, 0.6g of aromatic hyperbranched polyester H304 and 0.3g of dibutyltin dilaurate were added, and mechanically stirred for 1h , filtered, washed with acetone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com