An Automatic Guidance Vehicle Based on UWB Technology

A technology of automatic guided vehicle and ultra-wideband technology, applied in the field of automatic guided vehicle, can solve the problems of inaccurate positioning, increased use cost of storage system, excessive error, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the embodiments given in the accompanying drawings.

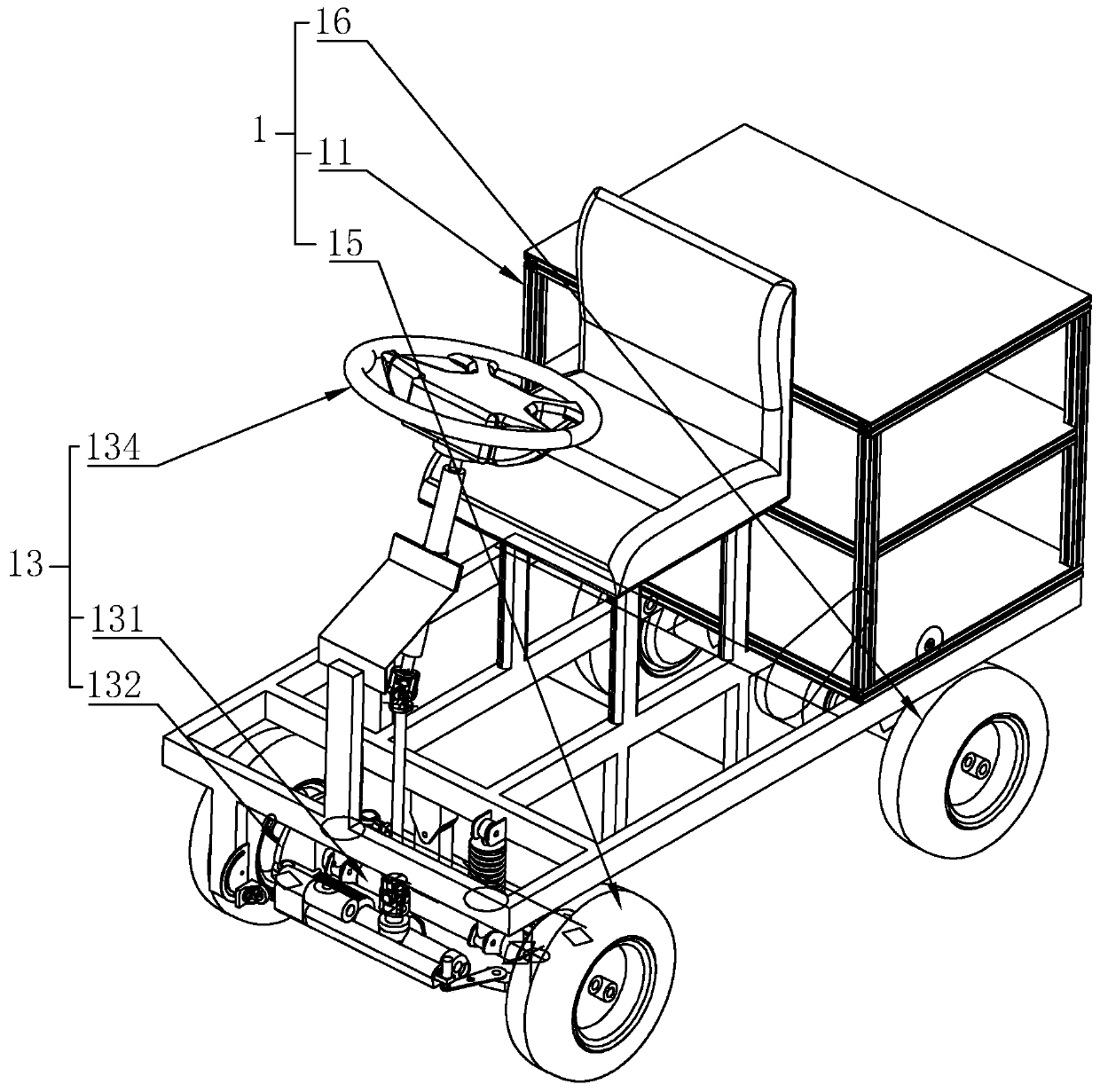

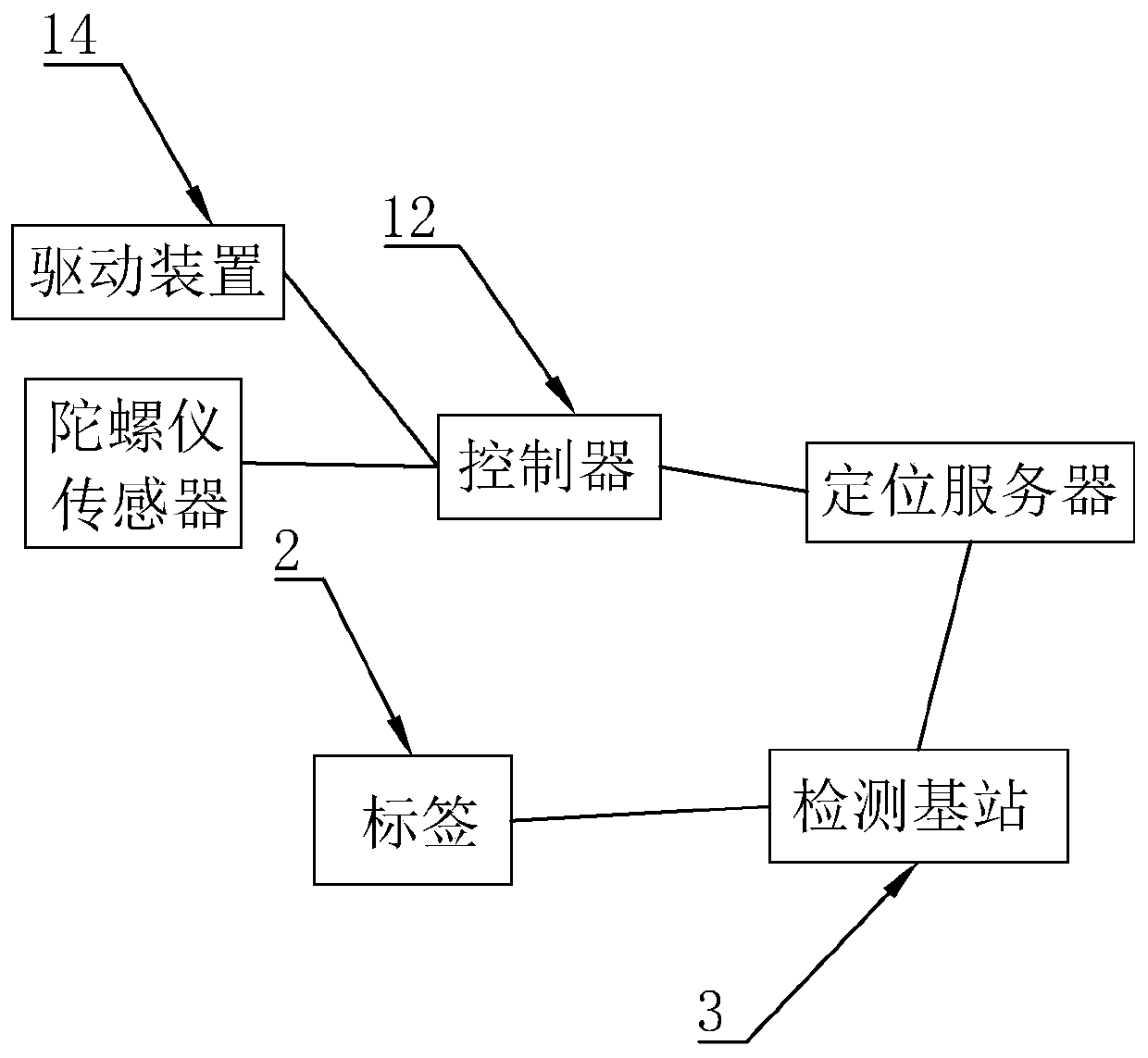

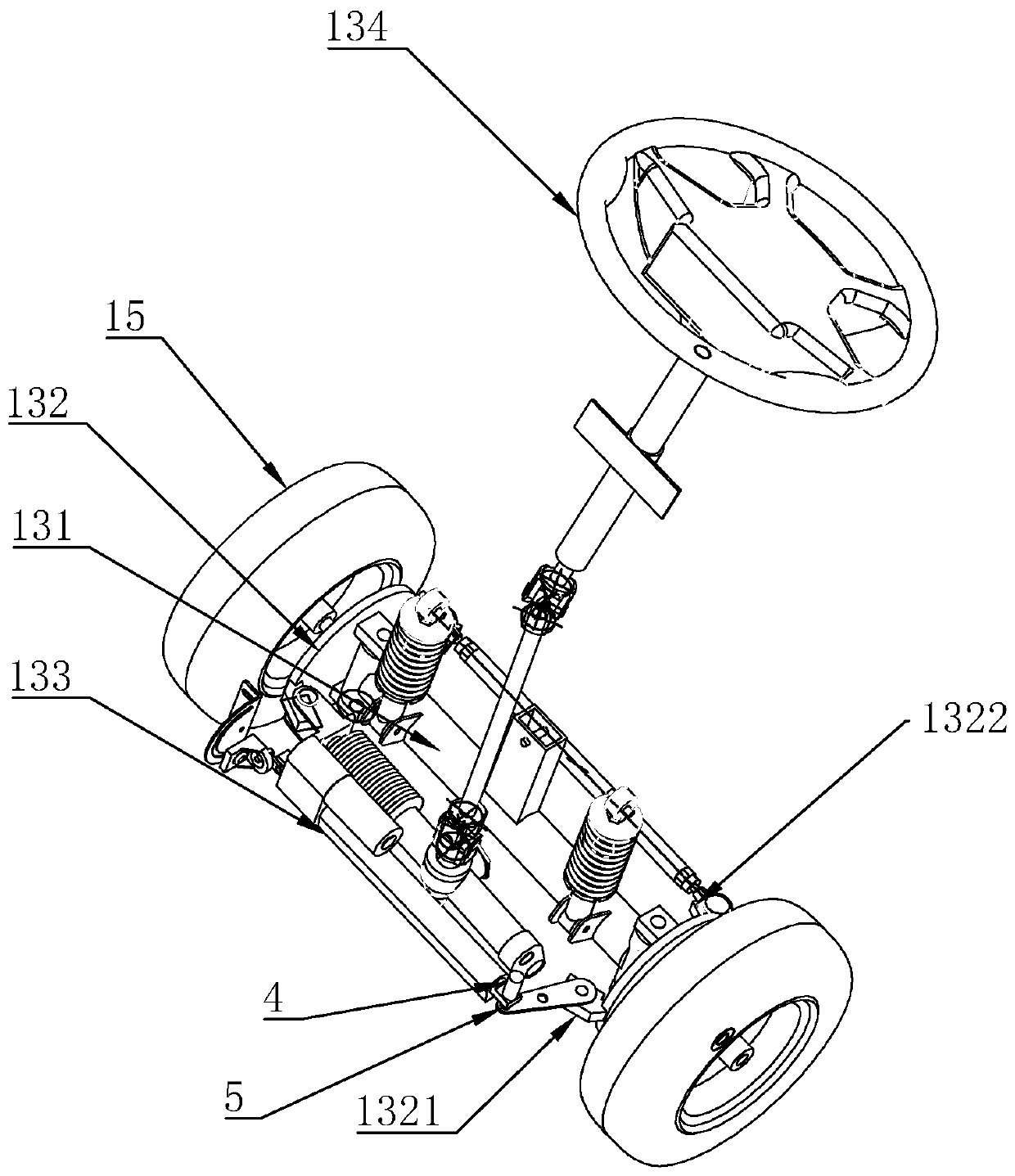

[0018] refer to Figures 1 to 4 As shown, an automatic guided vehicle based on ultra-wideband technology in this embodiment includes a transport vehicle 1, a label 2 arranged on the transport vehicle 1, and several detection base stations 3. Several detection base stations 3 are set around the warehouse to detect The scope covers the entire warehouse, and the detection base station 3 is coupled with a positioning server, which is used to detect the distance from the tag 2 and input it into the positioning server, and calculate the position of the positioning tag 2 through the positioning server. The transport vehicle 1 includes a vehicle The body 11 , the front wheels 15 and the rear wheels 16 arranged under the vehicle body 11 , and the controller 12 , the steering gear 13 and the driving device 14 all arranged on the vehicle body 11 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com