Fettling device for ceramic processing

A ceramic processing and blank trimming technology, which is applied in the direction of ceramic molding machines, manufacturing tools, auxiliary molding equipment, etc., can solve problems such as dropped by hand, incomplete blank trimming, and too tight hand holding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

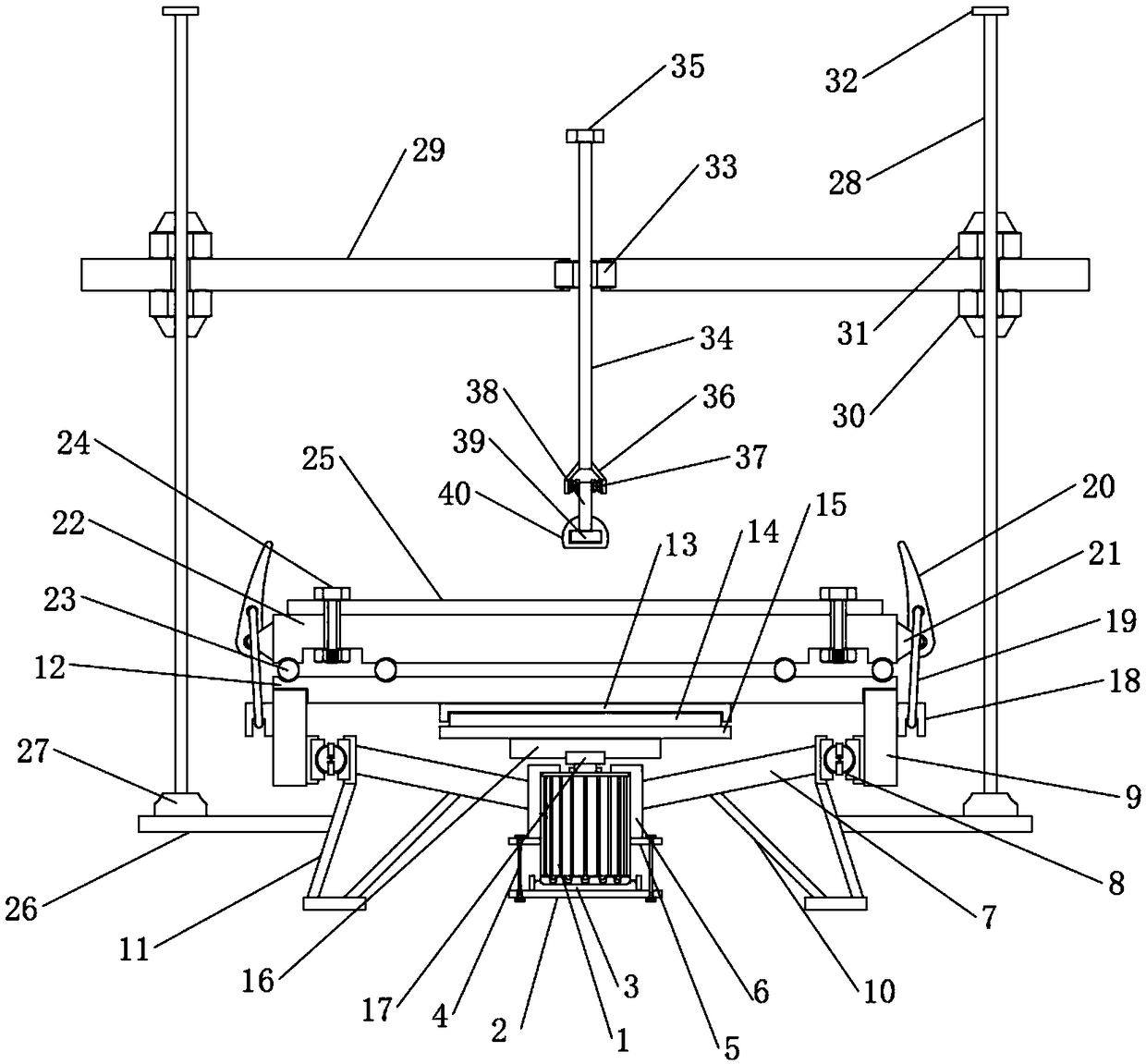

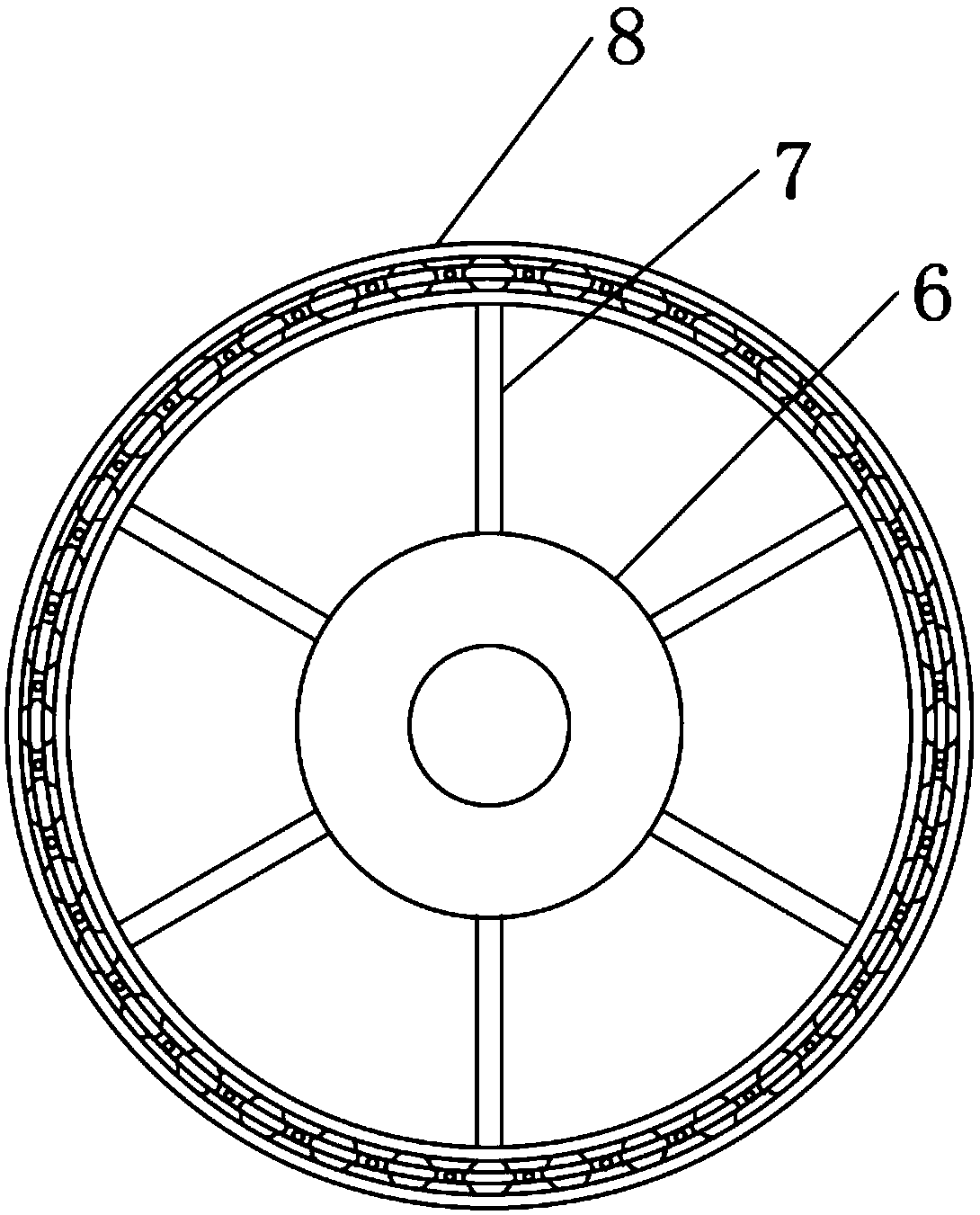

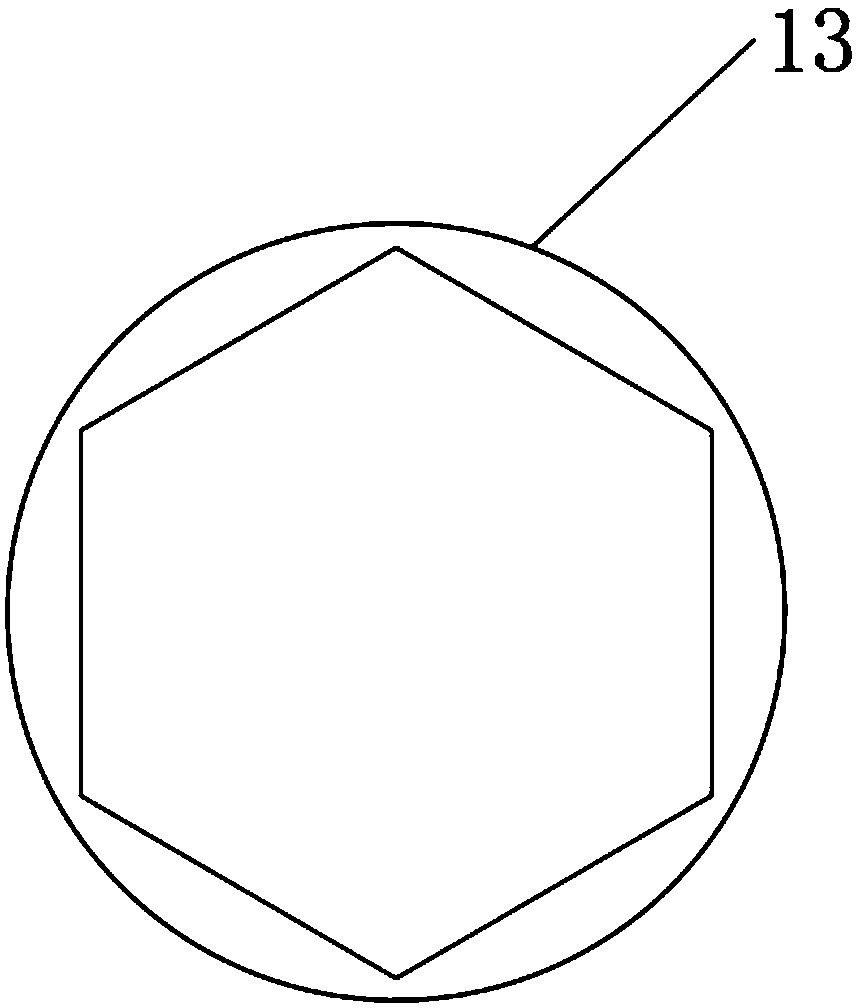

[0021] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a trimming device for ceramic processing, including a drive motor 1, the output end side of the drive motor 1 is provided with a top operating plate 22, and the top operating plate 22 is far away from One side of the drive motor 1 is provided with a pressure block 39, and the side of the drive motor 1 is connected to the bottom backing plate 12 through the bottom connecting bearing 8, and the bottom backing plate 12 is clamped with the top operation plate 22, so The end of the drive motor 1 away from the output end is arranged on the bottom splint 2 of the motor, and the side of the bottom splint 2 of the motor is connected with a bolt group connecting flange 5 through several motor fixing bolt groups 4, and the bolt group connecting flange 5 Welded on a port of the motor top fixed frame 6, the motor top fixed frame 6 is clamped on the output end of the drive motor 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com