Tree annual ring sample polishing device by using cutters and convex surface type grinding wheel phased scraping

A technology for tree rings and polishing devices, which is applied in grinding/polishing safety devices, grinding drive devices, grinding/polishing equipment, etc. Slip and other problems to achieve the effect of reducing slip displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

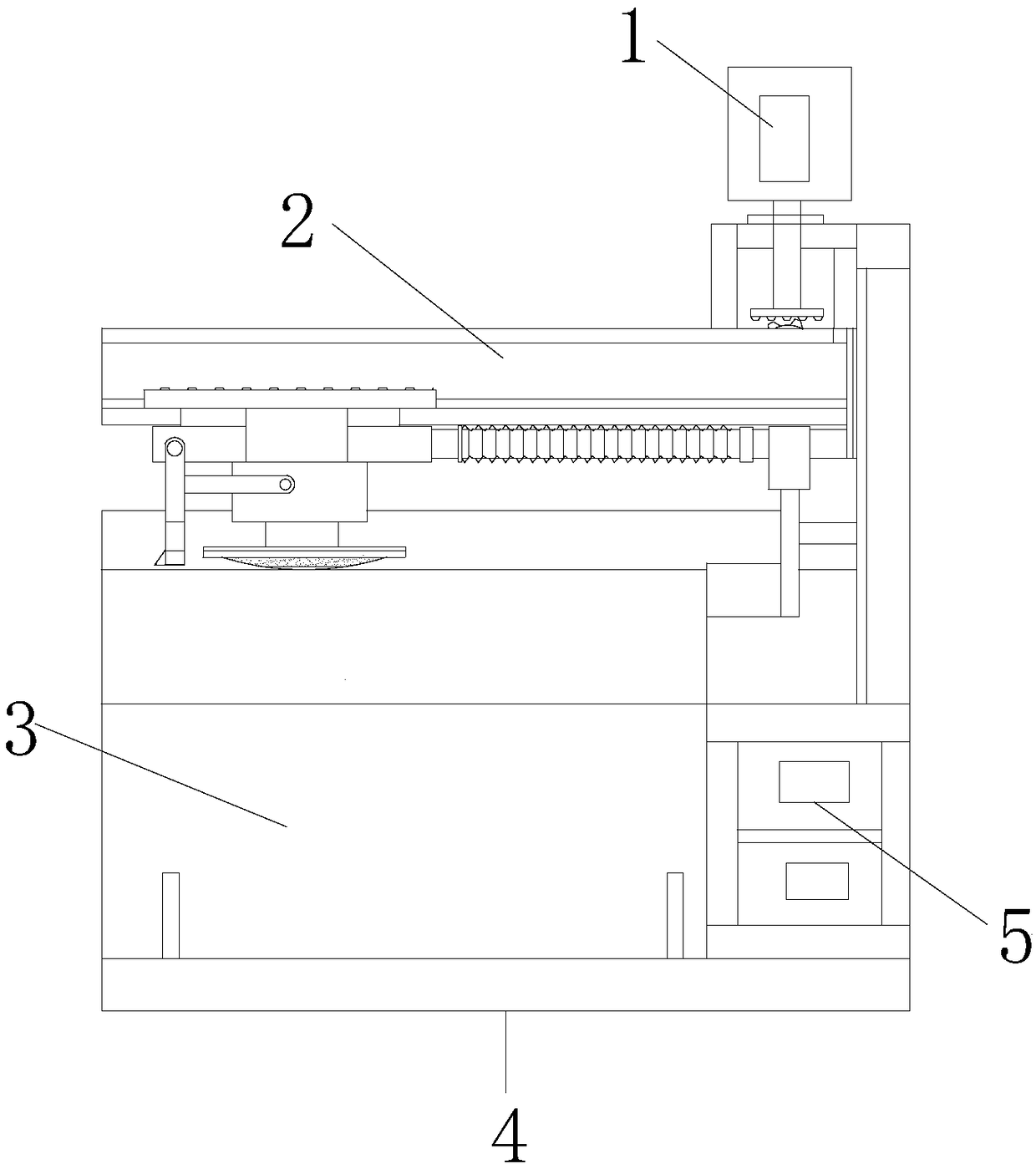

[0028] see figure 1, the present invention provides a tree ring sample polishing device that uses a knife and a convex grinding wheel to scrape and grind in stages. The unit 5 is located on the upper end surface of the base 4 and is movably connected with the base 4. The fixed base 3 is arranged on the upper surface of the base 4 and is mechanically connected with the base 4. The intelligent grinding device 2 is located on the upper side of the fixed base 3. The end face is welded together with the base 4. The bidirectional motor 1 is embedded in the intelligent smoothing device 2 and is movably connected with the intelligent smoothing device 2. The lower end face of the base 4 is provided with two parallel rubber Pads, the rubber pads parallel to each other can better reduce the vibration of the equipment during operation.

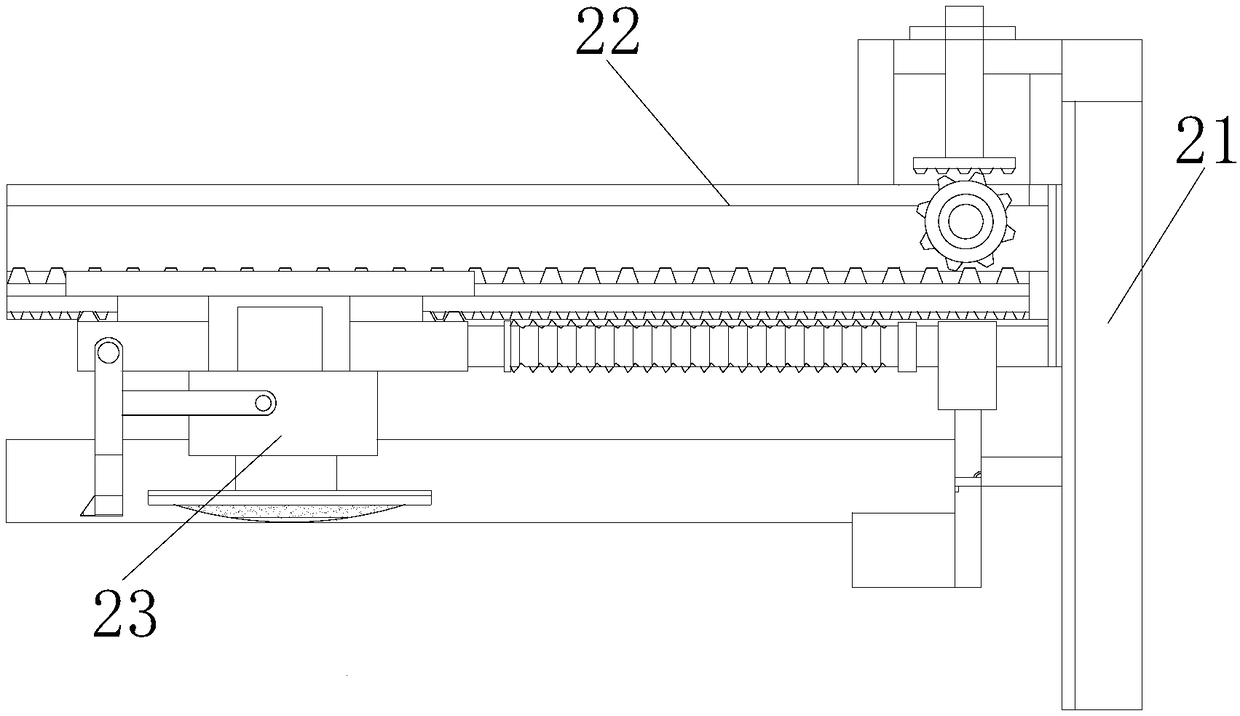

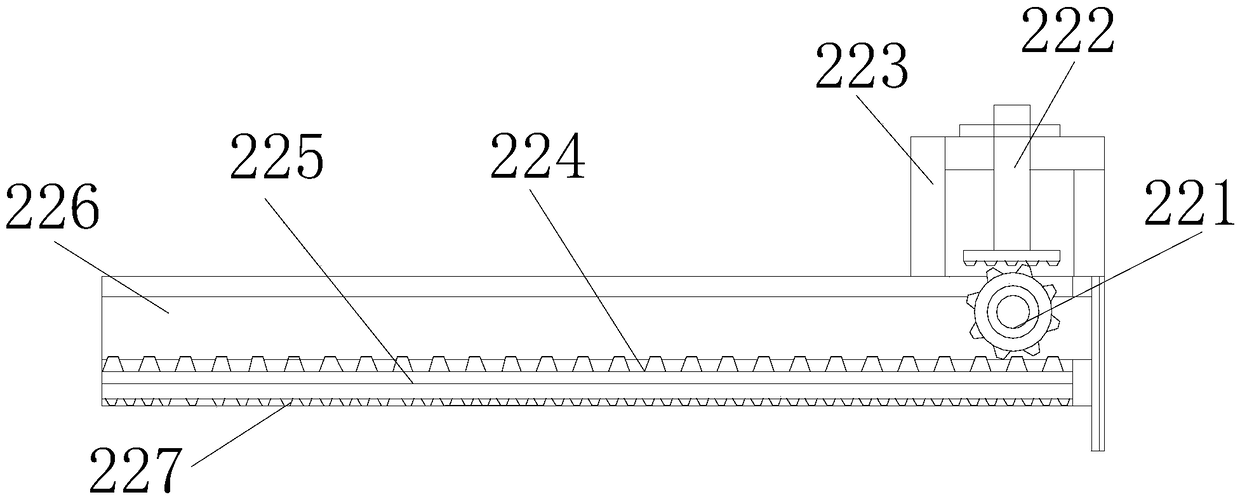

[0029] see figure 2 , the present invention provides a tree ring sample polishing device that uses a knife and a convex grinding wheel to scrape and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com