Highly uniform micro-cone array structure preparation method

A technology with an array structure and height, applied in welding equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of poor uniformity of the microcone array structure, inability to process large areas, poor material universality, etc., and achieve size and shape structure Accurate, optimal design, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

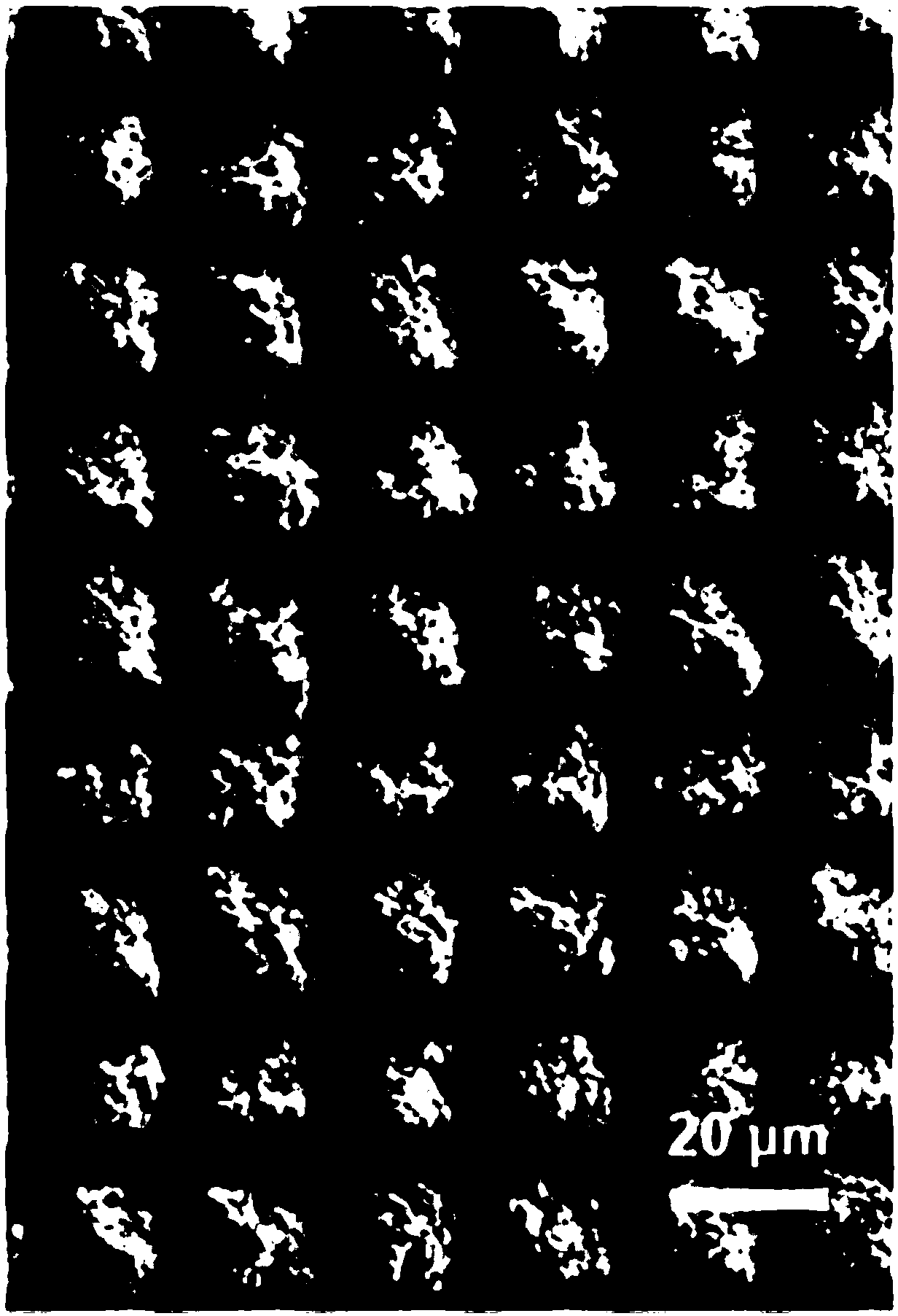

[0023] Embodiment 1: In this embodiment, a method for preparing a highly uniform microcone array structure is specifically carried out in the following steps:

[0024] 1. Adjust the height of the substrate through the three-dimensional mobile stage, position the sample, and focus the laser focus center on the upper surface of the sample;

[0025] 2. Set laser single pulse energy;

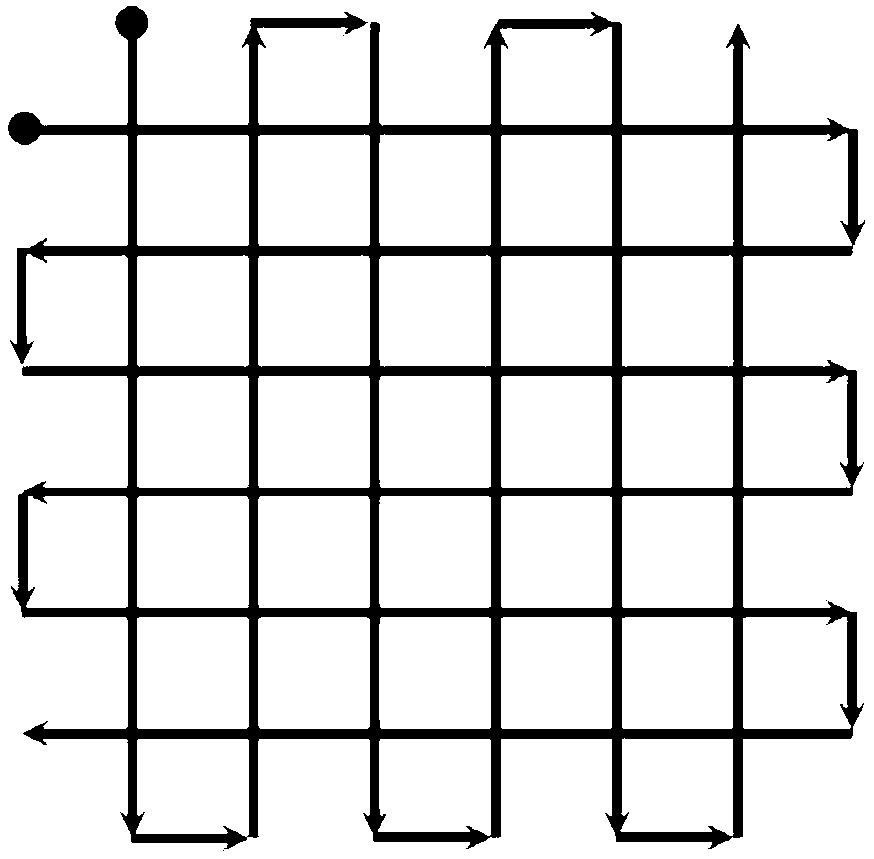

[0026] 3. Use the three-dimensional mobile stage to set the plane grid path, and then use the laser to scan the upper surface of the sample;

[0027] 4. Using deionized water to ultrasonically clean the processed sample, and completing the preparation method of the highly uniform microcone array structure.

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 1, the sample material is an aluminum plate, a single crystal silicon wafer or PDMS. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 2, the laser single pulse energy is set to 40-120 μJ. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com