Shielding tool used during spraying glue on automobile blind window welding spot and glue spraying method thereof

A blind window and tooling technology, applied in the direction of injection devices, etc., can solve the problems of affecting the aesthetics of the outer surface of the car body, uneven graininess on the rubber surface, and high requirements for work experience, so as to reduce operating costs, improve aesthetics, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

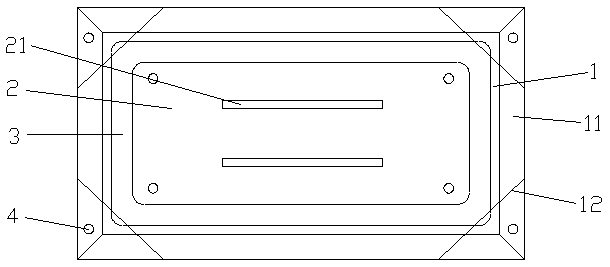

[0028] Please see attached figure 1 , a kind of shielding tooling for welding spot spraying of blind windows of automobiles, comprising blind window tooling 1 and blind window shielding tooling 2, blind window shielding tooling 2 is a frame structure made according to the window frames of blind window models, and blind window tooling 1 according to The blind window form of the blind window model is made. The blind window tooling 1 is set in the blind window shielding tool 2 and is limited to form the main body of the blind window tooling. There is a glue spraying area between the blind window tooling 1 and the blind window shielding tooling 2. 3. It is used to simulate the blind window structure of a car. The main body of the shielding tool is equipped with an adsorption structure 4. The main body of the shielding tool is adsorbed to the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com