Method and device for increasing nitric acid utilization rate in production of metronidazole, and application

A utilization rate and nitric acid technology, which is applied in the fields of resource recovery and chemical synthesis, can solve the problems of nitrogen oxide pollution, low utilization rate of nitric acid, and high cost of absorption equipment, so as to improve utilization rate, accelerate gas-liquid exchange speed, and absorption speed Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

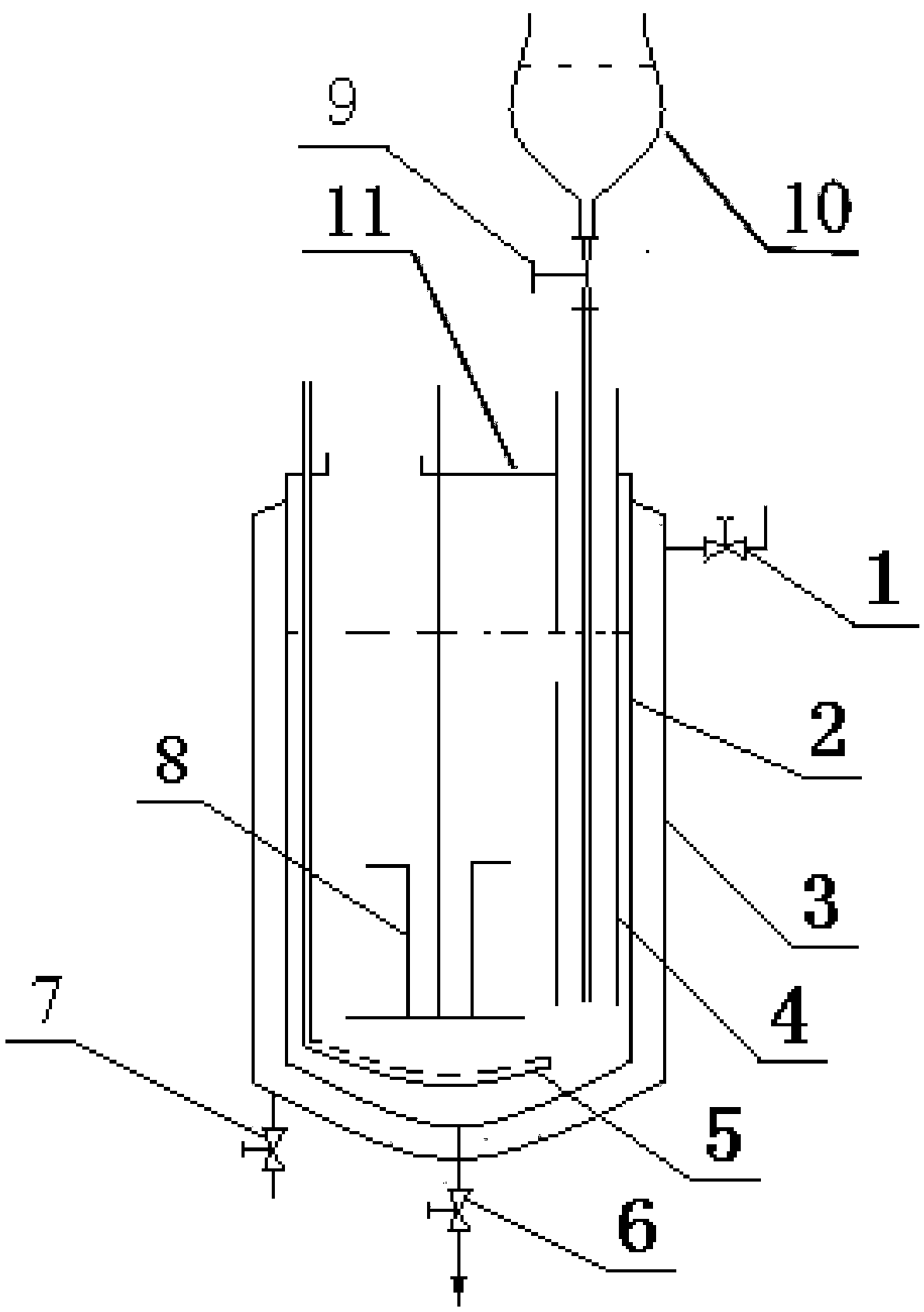

[0060] figure 1 The structure of the device provided by the present invention is shown. A device for improving the utilization rate of nitric acid in production, comprising a reaction kettle 2 , a draft pipe 4 , a gas distributor 5 and a dropping funnel 10 .

[0061] The reaction kettle 2 has a loam cake 11 with a hole, a discharge valve 6 is arranged at the lower end, and an agitator 8 is arranged in the kettle. Preferably, the reactor 2 has a double-layer structure, the inner layer is used for material reaction, and the outer layer is used for condensation or heating of the introduced medium. The upper end of the outer layer of the reaction kettle 2 is provided with an inlet valve 1, and the lower end is provided with an outlet valve 7.

[0062] The guide tube 4 is a cylindrical body with upper and lower openings, and a guide hole is opened on the side wall; the guide tube 4 penetrates the upper cover 11 and is arranged in the reaction kettle 2 . The dropping funnel 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com