Fumigation insect removal tablet putting mechanism for granary

A granary and cartridge technology, which is applied to fumigators, agricultural machinery and implements, devices for catching or killing insects, etc. Insect gas can not effectively cover the granary and other problems, to achieve the effect of easy identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

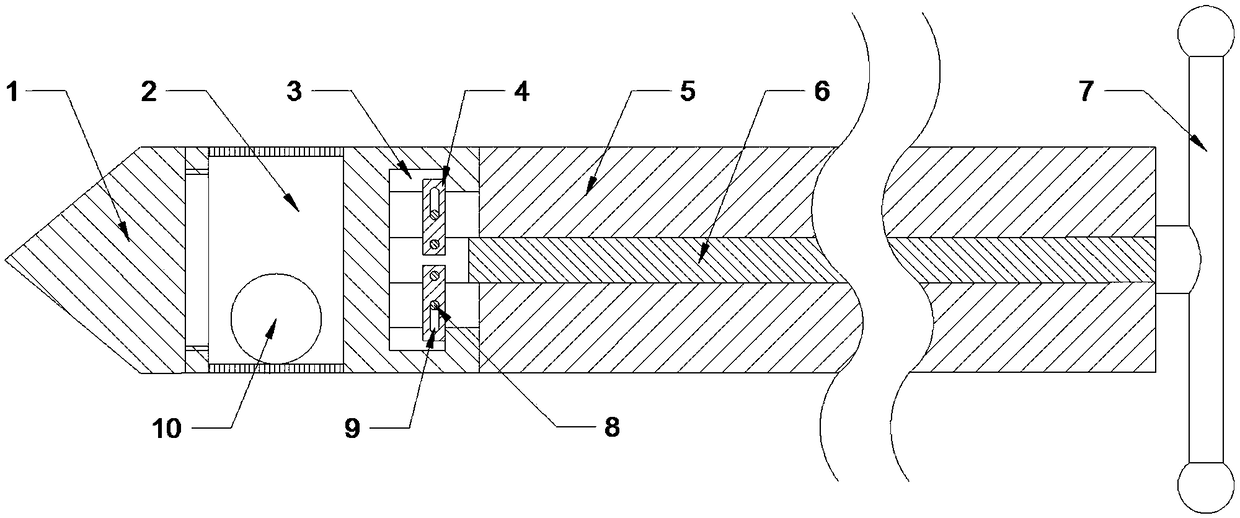

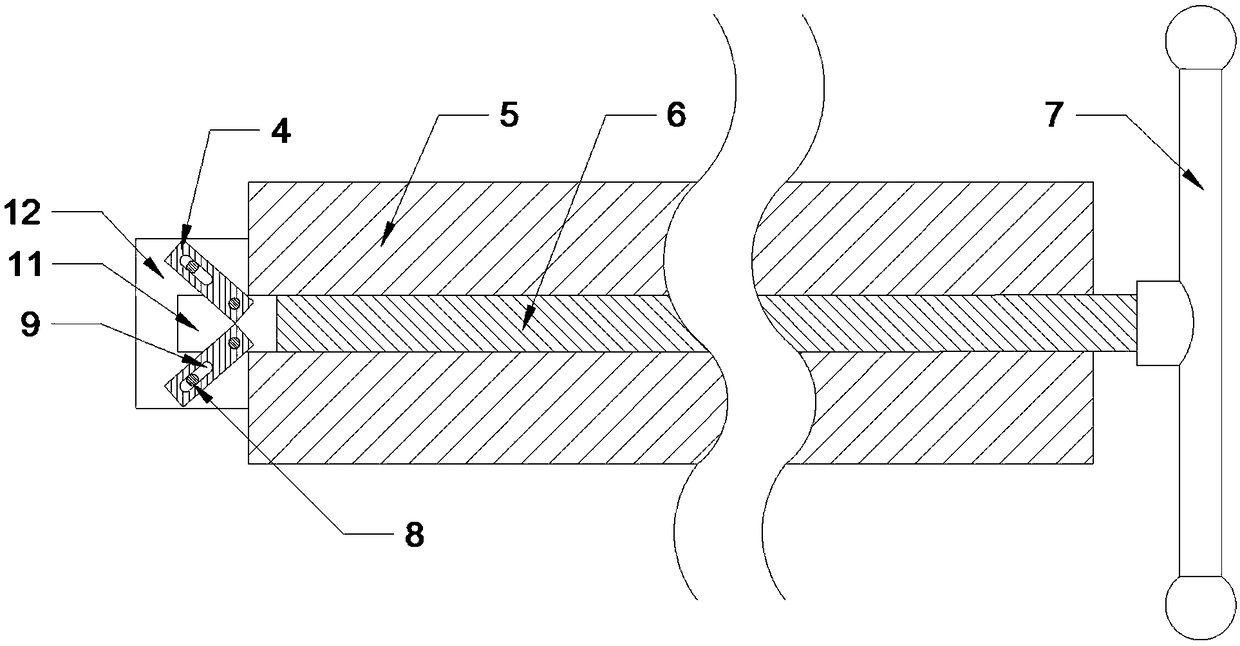

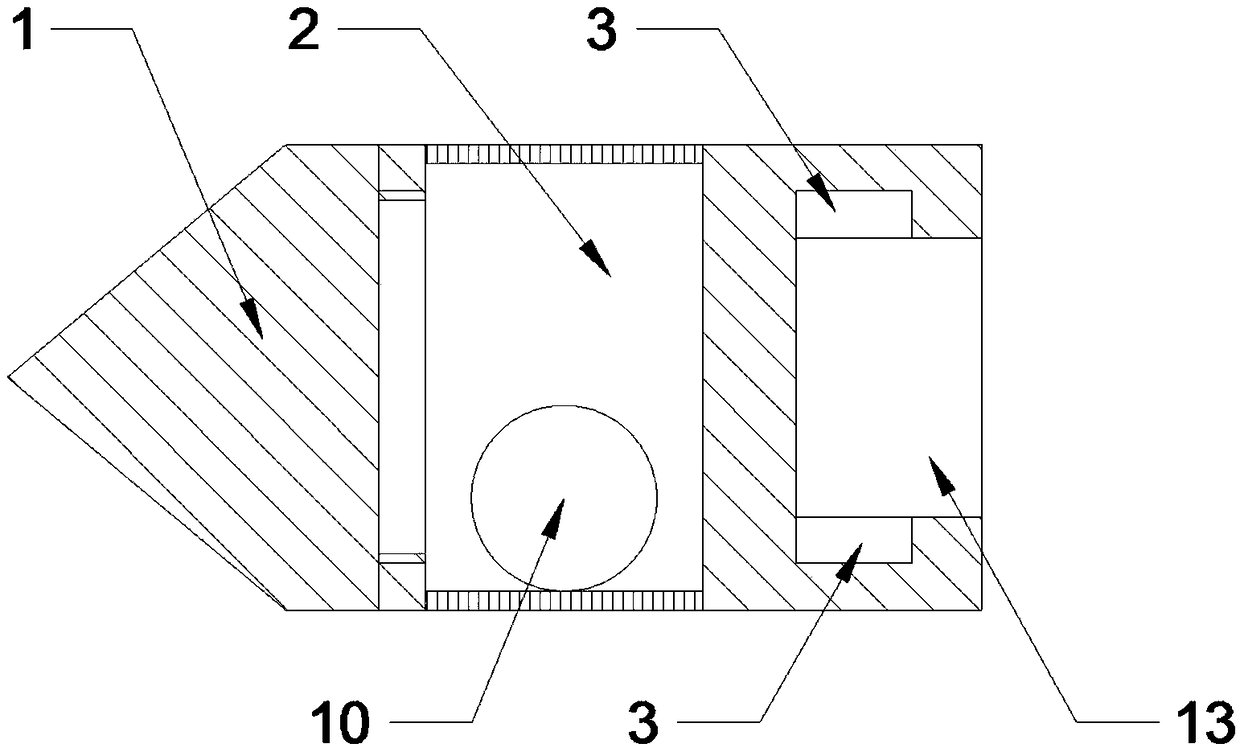

[0031] see Figure 1~6 , a granary fumigation deworming dosing mechanism, comprising an insertion rod 5, the central axis of the insertion rod 5 is provided with a through hole 14, the front end of the insertion rod 5 is provided with an opening slot 12, and the opening slot 12 is provided with a limit column 8; the through hole The push-pull rod 6 is sleeved in 14, and the front end of the push-pull rod 6 is provided with an opening groove 2 11, and the front end of the push-pull rod 6 and one end of the bayonet pin 4 are hinged in the opening groove 2 11, and the bayonet pin 4 is provided with a sliding groove 9, and the limit post 8 is locked. In the sliding groove 9; the front end of the insertion rod 5 is inserted into the interface groove 13 at the rear end of the drug injection barrel 2 to connect with the drug injection barrel 2, and the inner wall of the interface groove 13 is provided with a card slot 3 for bayonet pin 4 insertion.

[0032] In this example, when the ...

Embodiment 2

[0034] see Figure 1~6 , a granary fumigation deworming dosing mechanism, comprising an insertion rod 5, the central axis of the insertion rod 5 is provided with a through hole 14, the front end of the insertion rod 5 is provided with an opening slot 12, and the opening slot 12 is provided with a limit column 8; the through hole The push-pull rod 6 is sleeved in 14, and the front end of the push-pull rod 6 is provided with an opening groove 2 11, and the front end of the push-pull rod 6 and one end of the bayonet pin 4 are hinged in the opening groove 2 11, and the bayonet pin 4 is provided with a sliding groove 9, and the limit post 8 is locked. In the sliding groove 9; the front end of the insertion rod 5 is inserted into the interface groove 13 at the rear end of the drug injection barrel 2 to connect with the drug injection barrel 2, and the inner wall of the interface groove 13 is provided with a card slot 3 for bayonet pin 4 insertion.

[0035] In this example, the housi...

Embodiment 3

[0039] see Figure 1~6 , a granary fumigation deworming dosing mechanism, comprising an insertion rod 5, the central axis of the insertion rod 5 is provided with a through hole 14, the front end of the insertion rod 5 is provided with an opening slot 12, and the opening slot 12 is provided with a limit column 8; the through hole The push-pull rod 6 is sleeved in 14, and the front end of the push-pull rod 6 is provided with an opening groove 2 11, and the front end of the push-pull rod 6 and one end of the bayonet pin 4 are hinged in the opening groove 2 11, and the bayonet pin 4 is provided with a sliding groove 9, and the limit post 8 is locked. In the sliding groove 9; the front end of the insertion rod 5 is inserted into the interface groove 13 at the rear end of the drug injection barrel 2 to connect with the drug injection barrel 2, and the inner wall of the interface groove 13 is provided with a card slot 3 for bayonet pin 4 insertion.

[0040] In this example, a handle 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com