LED capacitance current-limiting protection circuit

A protection circuit and capacitor current-limiting technology, applied in the field of LED capacitor current-limiting protection circuit, can solve the problems such as the inability to increase the number of LEDs and the inability to form a high-power LED group, achieving a simple structure, solving instantaneous impact, and high circuit efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

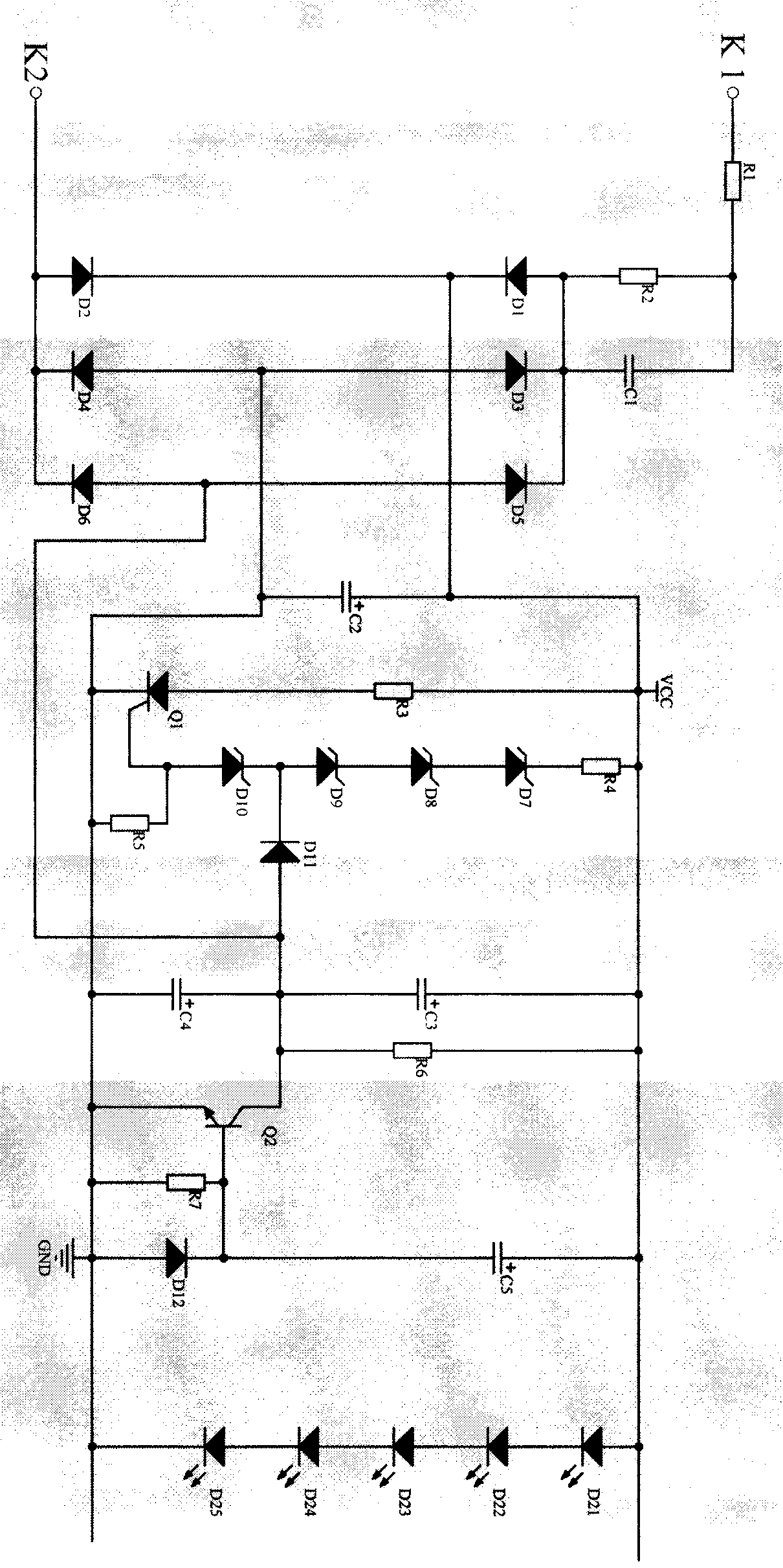

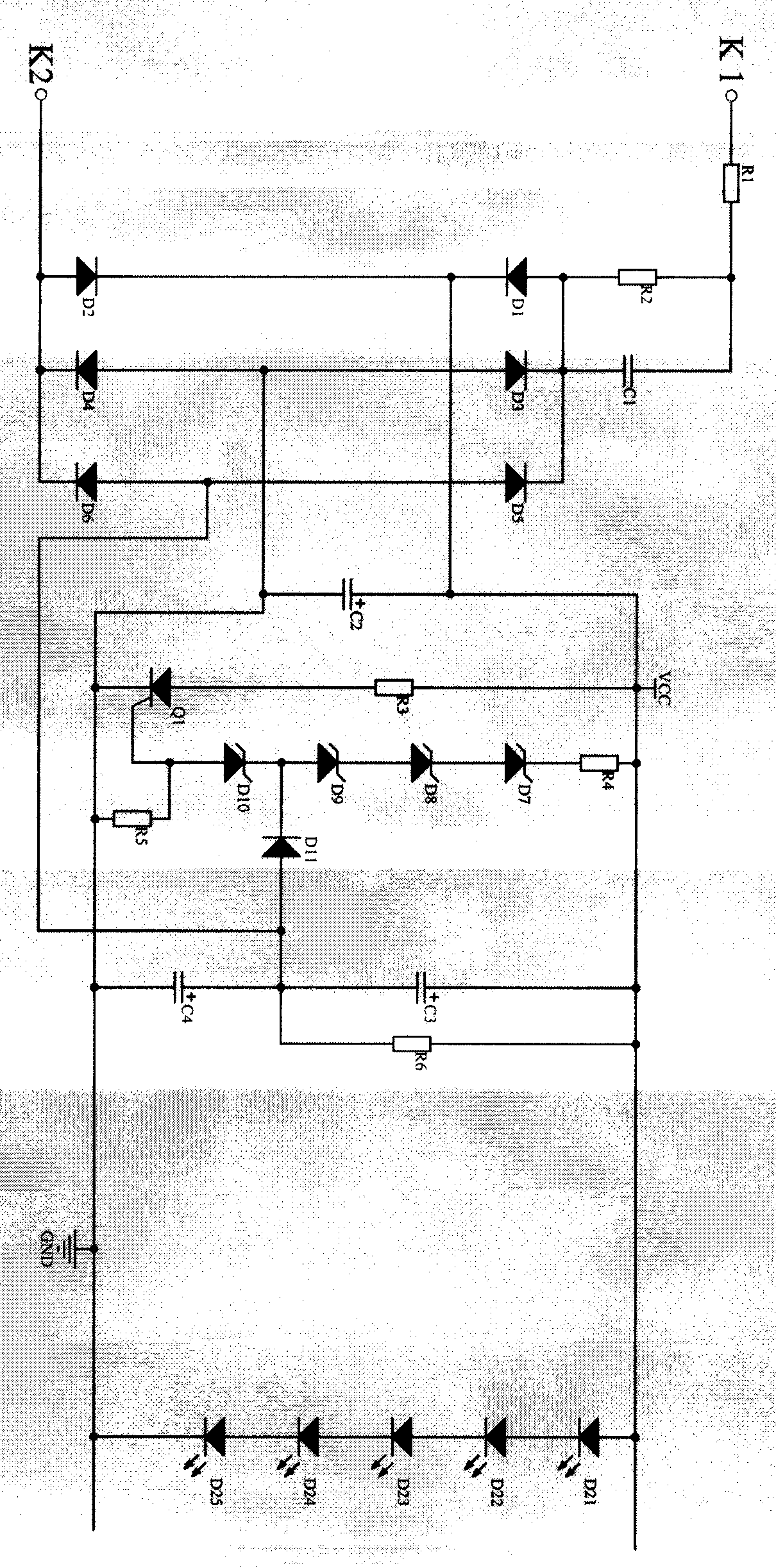

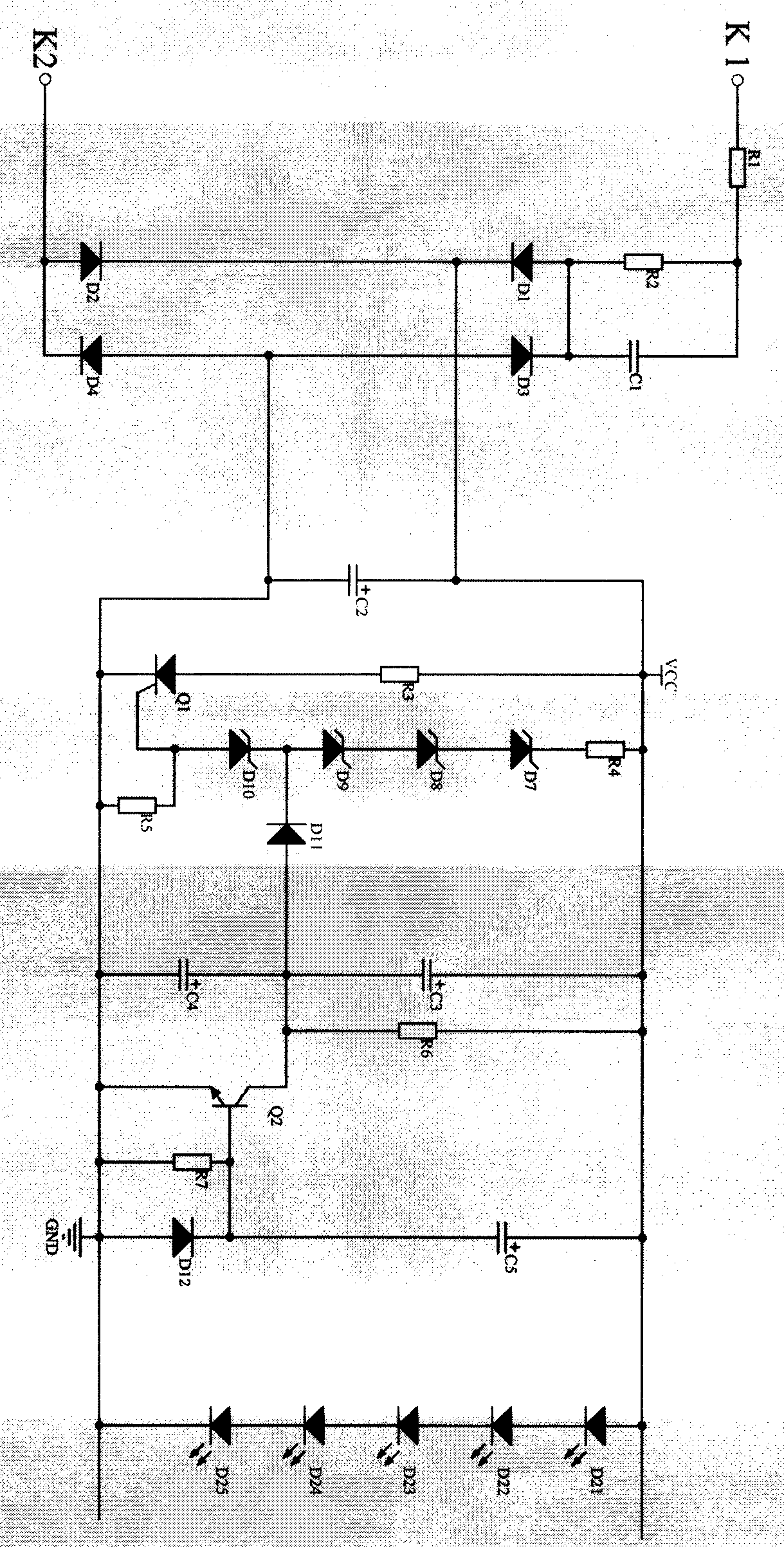

[0013] figure 1 In the LED capacitor current limiting protection circuit, the contacts K1 and K2 are connected to the 220V AC power supply through the switch, the resistor R2 is connected in parallel with the capacitor C1, one end of the resistor R1 is connected to K1, the other end of R1 is connected to one end of C1, the other end of C1 is connected to the anode of diode D1 and diode D3 Negative pole, K2 is connected to the positive pole of diode D2 and the negative pole of diode D4, the negative poles of D1 and D2 are connected to the positive power supply VCC, the positive poles of D3 and D4 are connected to the power ground, the positive pole of capacitor C2 is connected to VCC, the negative pole of C2 is grounded, the positive pole of the LED group is connected to VCC, and the negative pole is grounded. Ground the cathode of the thyristor Q1, connect the anode of Q1 to VCC in series with resistor R3, connect the resistor R5 in parallel between the trigger pole and the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com