Anode material and manufacturing method thereof and lithium-sulfur battery

A positive electrode material and a positive electrode technology, applied in the field of positive electrode materials and their preparation, and lithium-sulfur batteries, can solve the problems of reducing the cycle stability of lithium-sulfur batteries, reducing the cycle stability of lithium-sulfur batteries, and poor cycling stability of lithium-sulfur batteries, etc. Good cycle stability, improved cycle stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

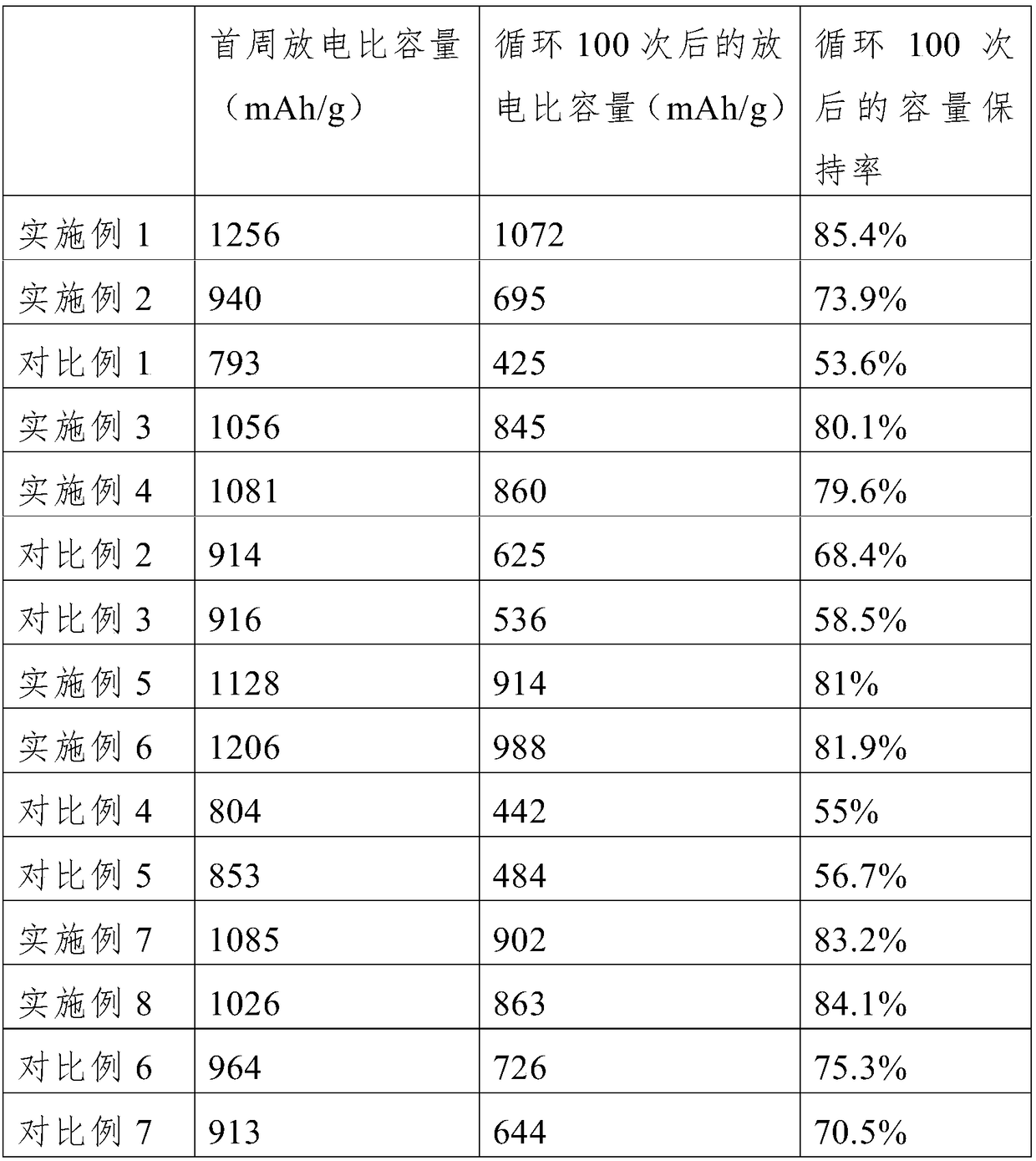

Examples

Embodiment approach

[0039] According to one embodiment of the cathode material of the present invention, the porous C 3 N 4-x The porosity is 20-30m 2 / g.

[0040] Porous C in the positive electrode material of the present invention 3 N 4-x The porosity is 20~30m 2 / g, while plain C 3 N 4 The porosity is only 9m 2 / g or so, so the positive electrode material of the present invention has a strong sulfur storage capacity, and the lithium ion battery using the positive electrode material of the present invention has good cycle performance.

[0041] According to another aspect of the present invention, a kind of preparation method of cathode material is provided, comprising steps:

[0042] S1: C containing holes3 N 4 Mixed with Mg, heated and reacted for a certain period of time to obtain porous C 3 N 4-x , where, 0

[0043] S2: in C containing pores 3 N 4-x Sulfur is loaded in the medium to obtain the positive electrode material.

[0044] The preparation method of the present inv...

Embodiment 1

[0071] In the preparation method of the positive electrode material of this embodiment, the C containing pores is first prepared 3 N 4 , the pore-containing C was obtained by mixing and heating thiourea and ammonium chloride 3 N 4 ; The mass ratio of thiourea to ammonium chloride is 1:1; the heating temperature is 500-600°C, and the heating time is 1-5h.

[0072] Then proceed to step S1: the obtained C containing pores 3 N 4 Mixed with Mg powder, heated and reacted for a certain period of time to obtain porous C 3 N 4-x , where, 03 N 4 The mass ratio of magnesium powder and magnesium powder is 3:1; the heating temperature is 600°C, and the reaction time is 1-5h; after the reaction is completed, wash with dilute acid and deionized water; the concentration of dilute acid is 0.5-1.5mol / L sulfuric acid or hydrochloric acid.

[0073] Finally, step S2 is performed: in the hole-containing C 3 N 4-xSulfur is loaded in the medium to obtain the positive electrode material. C ...

Embodiment 2

[0075] The other conditions of embodiment 2 and embodiment 1 are all the same, and the difference is that no ammonium chloride is added in embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com