Electromagnetic valve device with backflow preventing function and automatic sewage isolating function

A technology of anti-backflow and solenoid valve, which is applied in the direction of valve device, function valve type, valve operation/release device, etc. It can solve the problems of water splashing, unreasonable structure, and large space occupied, so as to avoid the backflow of sewage , compact structure and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

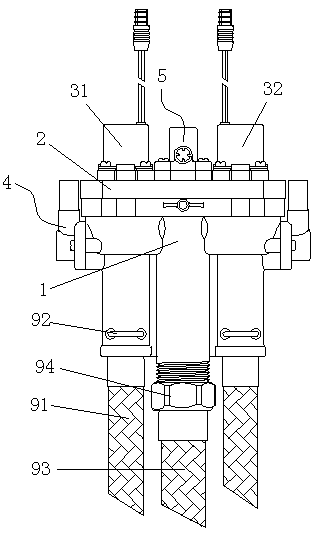

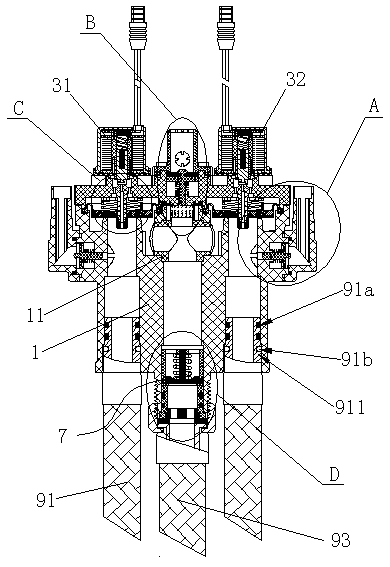

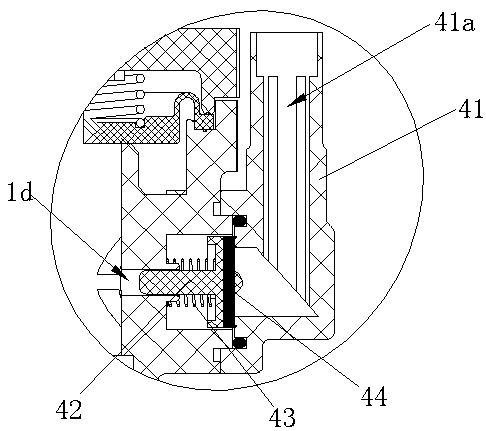

[0027] Such as Figure 1 to Figure 8 Shown is the structural representation of the present invention,

[0028] The reference signs are: valve body 1, water inlet 1a, first water outlet 1b, second water outlet 1c, vacuum breaking hole 1d, cleaning waterway interface 1e, four-way insert 11, filter screen 12, valve cover 2 , the first flushing solenoid valve 31, the second flushing solenoid valve 32, the vacuum breaking device 4, the vacuum breaking valve cover 41, the vent 41a, the vacuum breaking valve core 42, the vacuum breaking spring 43, the sealing rubber film 44, the anti-siphon device 5 , anti-siphon cover 51, air inlet 51a, overflow hole 51b, anti-siphon core 52, anti-siphon spring 53, anti-siphon rubber film 54, sealing diaphragm 61, diversion tube 62, pressure relief hole 62a, anti-blocking needle Spring 63, booster hole 64, one-way...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com