An ultra-thin vacuum pipe traffic separation door that can be embedded in the rail gap

A technology of vacuum pipes and isolation doors, which is applied to door/window fittings, wing leaf operating mechanisms, buildings, etc., and can solve the problems of ignoring the existence of rails and other continuous components, low efficiency, and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings.

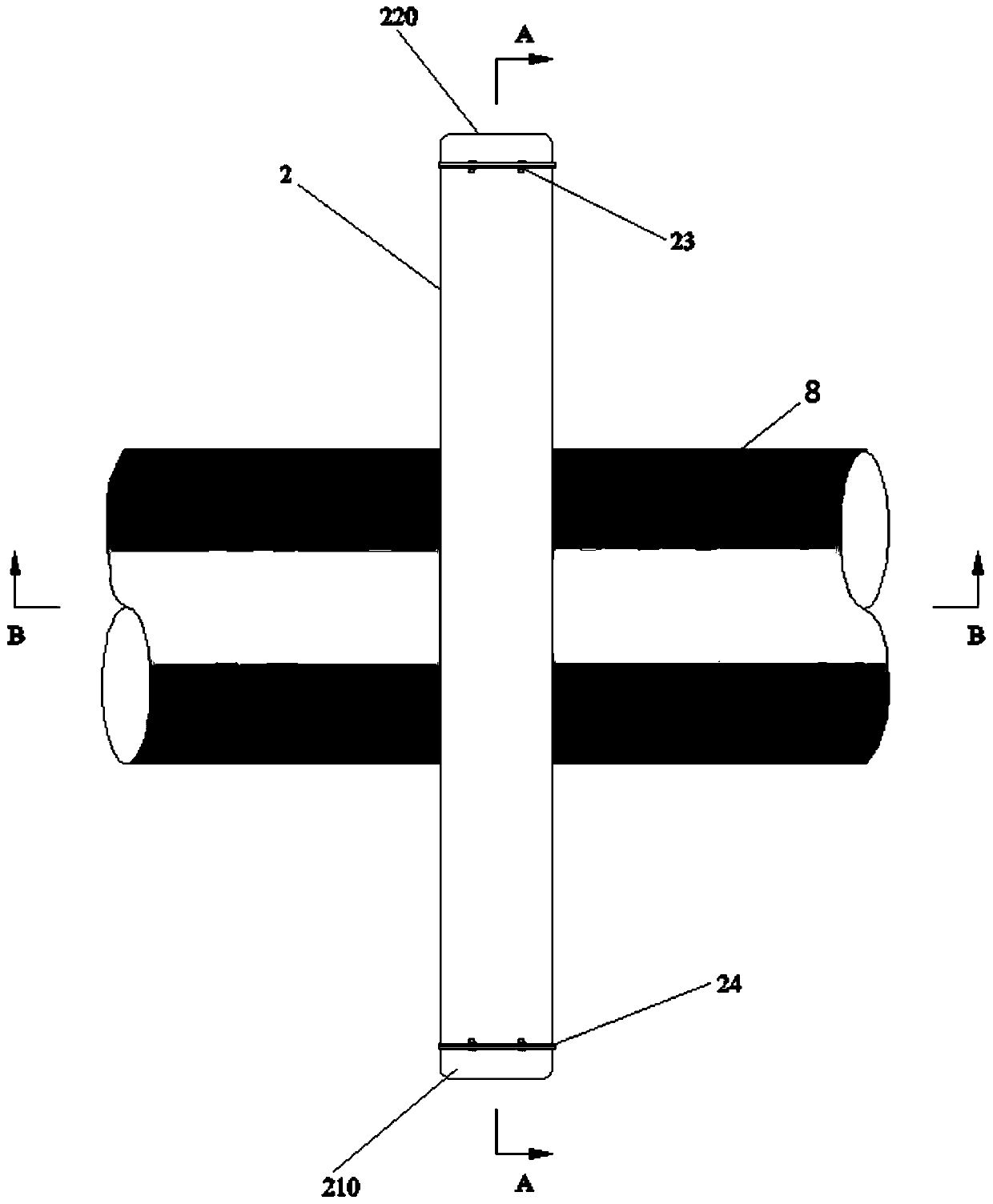

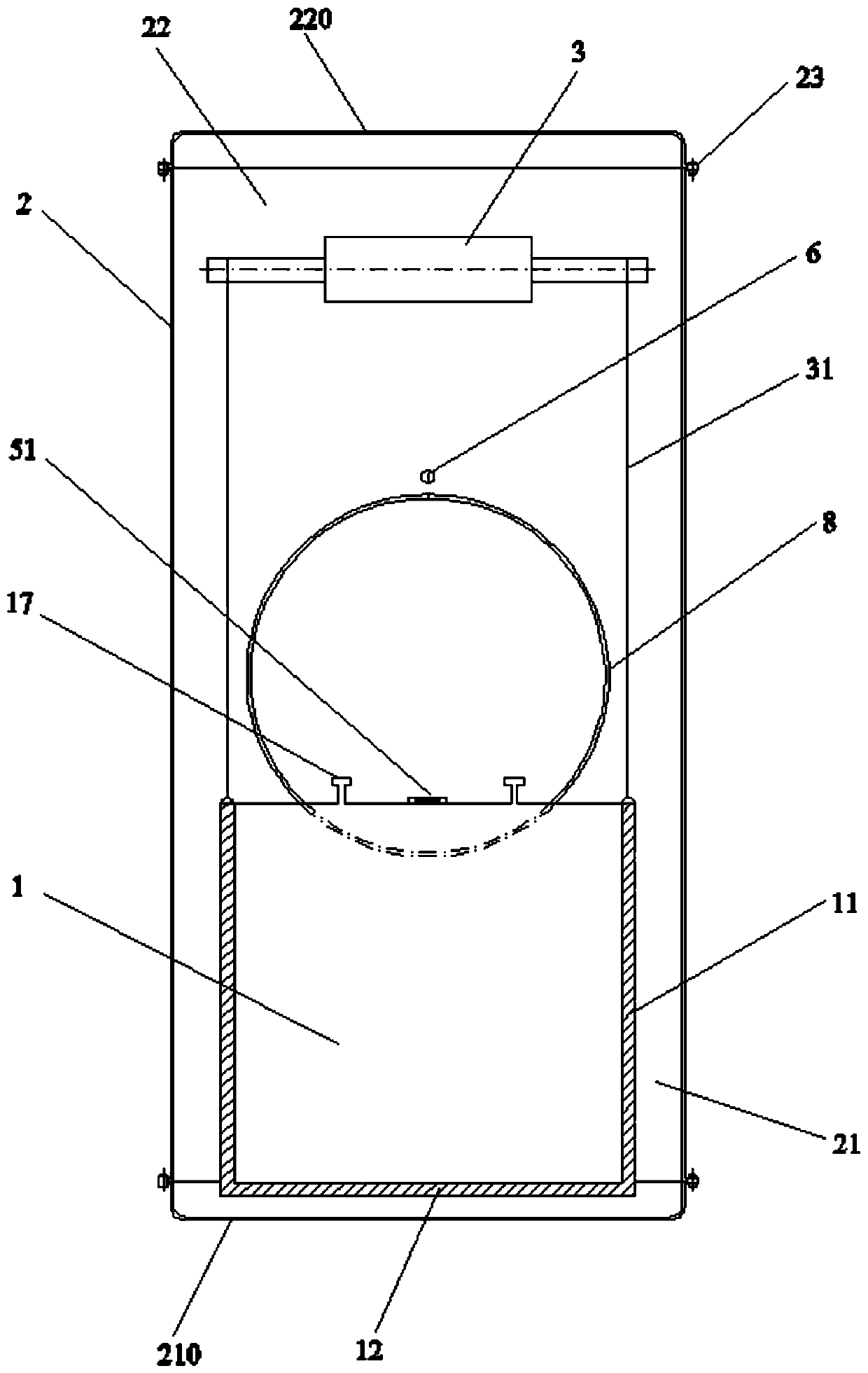

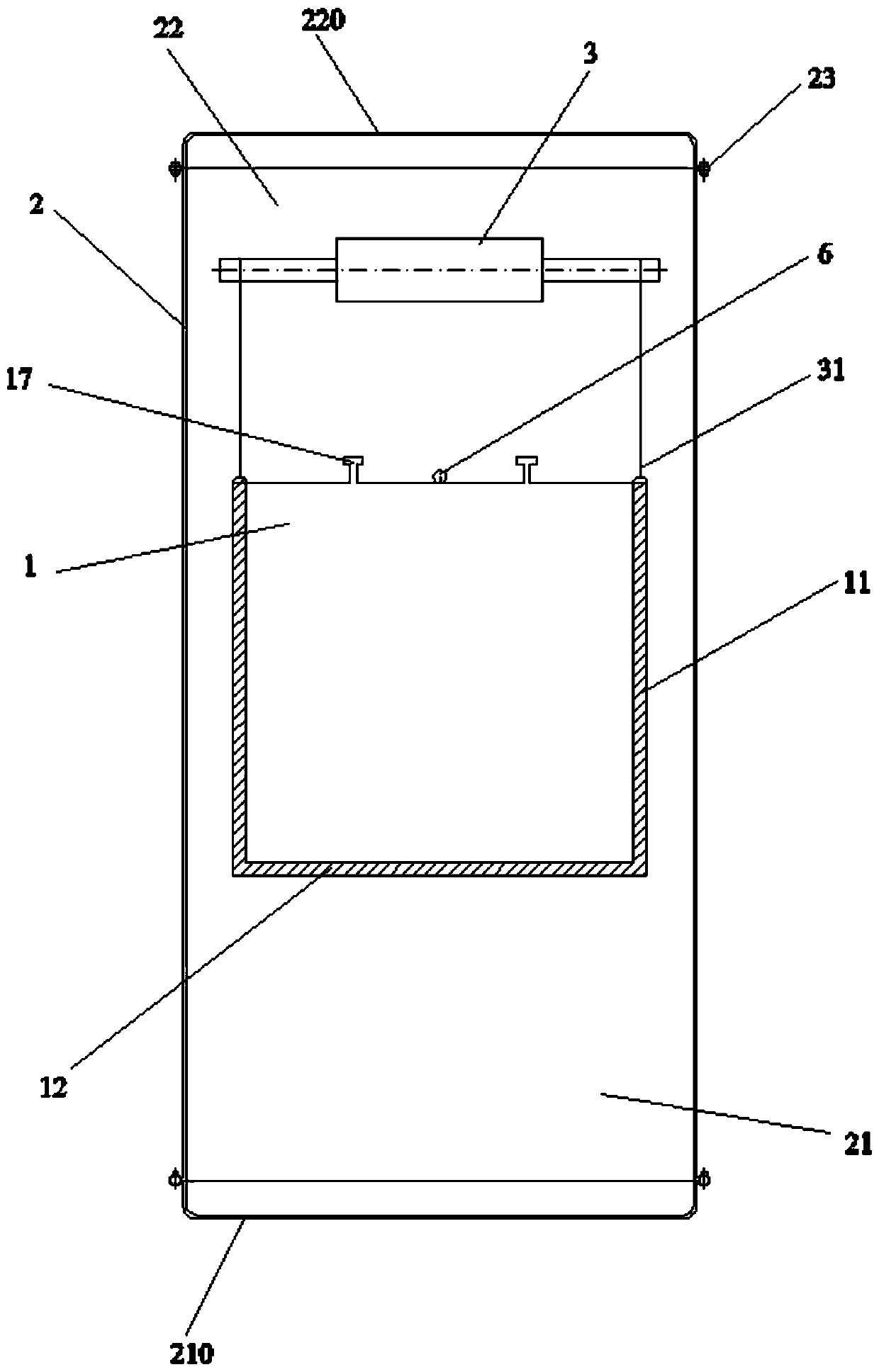

[0038] Such as Figure 1 to Figure 5As shown, a kind of ultra-thin vacuum pipe traffic isolation door that can be embedded in the rail gap includes a door chamber 2 arranged at the junction of two vacuum pipes 8. When the door chamber 2 is working normally, the inside of the door chamber 2 and the outside (vacuum pipe 8 outside and the inside of the vacuum pipe 8) are sealed and isolated to maintain good airtightness; the door chamber 2 includes an upper half door chamber 22 and a lower half door chamber 21, and the upper half door chamber 22 is provided with an isolation door 1, and the upper half door chamber A traction motor 3 is connected to the upper part of the door chamber 22, and the traction motor 3 is connected to the isolation door 1. The thickness of the isolation door 1 is less than 3mm. It is flush with and fits closely with the upper surface of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com