Road sweeper suction nozzle

A technology of road sweeper and suction nozzle seat, which is applied in road cleaning, construction, cleaning methods, etc. It can solve the problems of uneven negative pressure of air flow, limited inhalation particles, and inability to remove them, so as to ensure the suction effect and increase the equivalent diameter. , to avoid the effect of secondary dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

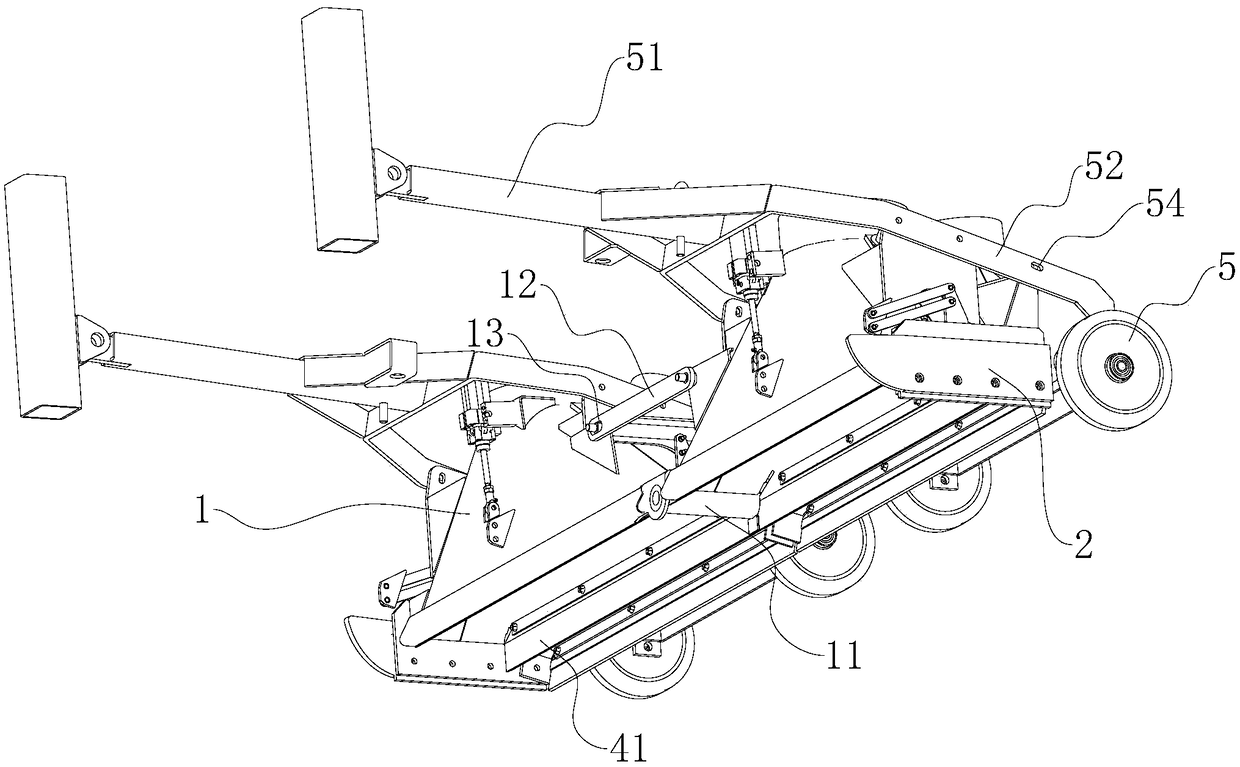

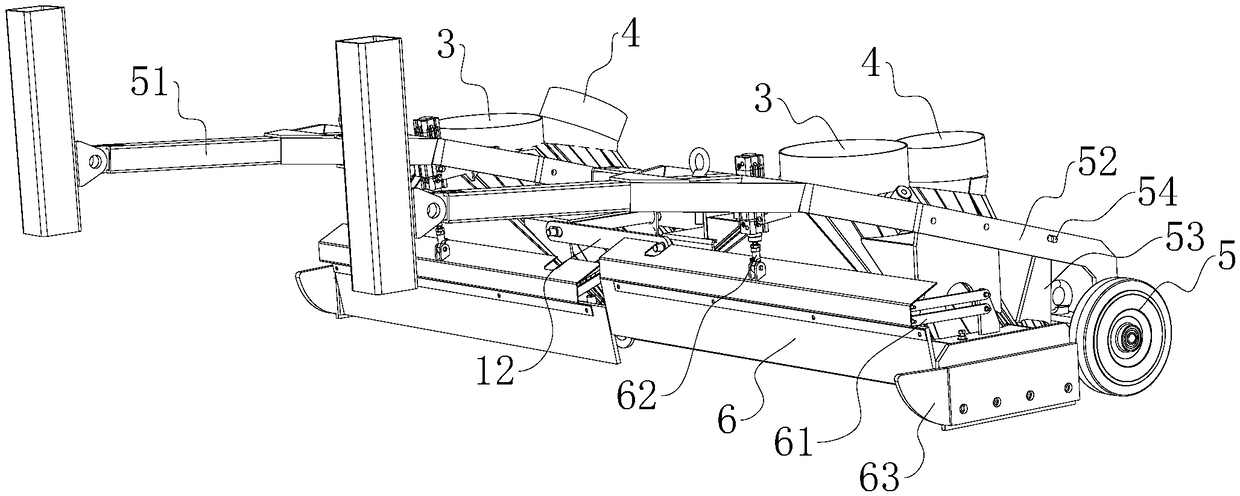

[0022] Such as Figure 1~3 For the preferred solution of the present invention, taking the direction of travel of the front of the car as an example, it includes a left suction nozzle 1, a right suction nozzle 2, a suction tube 3, an air blowing pipe 4, a walking wheel 5 and a baffle plate 6,

[0023] The left suction nozzle 1 and the right suction nozzle 2 are horizontally arranged side by side directly below the vehicle chassis, the bottom of the left suction nozzle 1 and the right suction nozzle 2 is a suction nozzle seat, and a suction cylinder 3 and a dustbin (not shown in the figure) are arranged on the top Link to each other, air blowing pipe 4 is equipped with in the direct rear of suction tube 3 (distinguish front and rear by vehicle advancing direction, the same below), and air blowing pipe 4 link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com