Four-screw drive system for vertical axis of CNC milling and boring machine

A screw drive and drive system technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of unstable operation, poor synchronization, high failure rate, etc., to reduce the failure rate, improve positioning accuracy, Effect of Seismic Performance Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure of the drive system of the present invention will be described in conjunction with the accompanying drawings and specific embodiments.

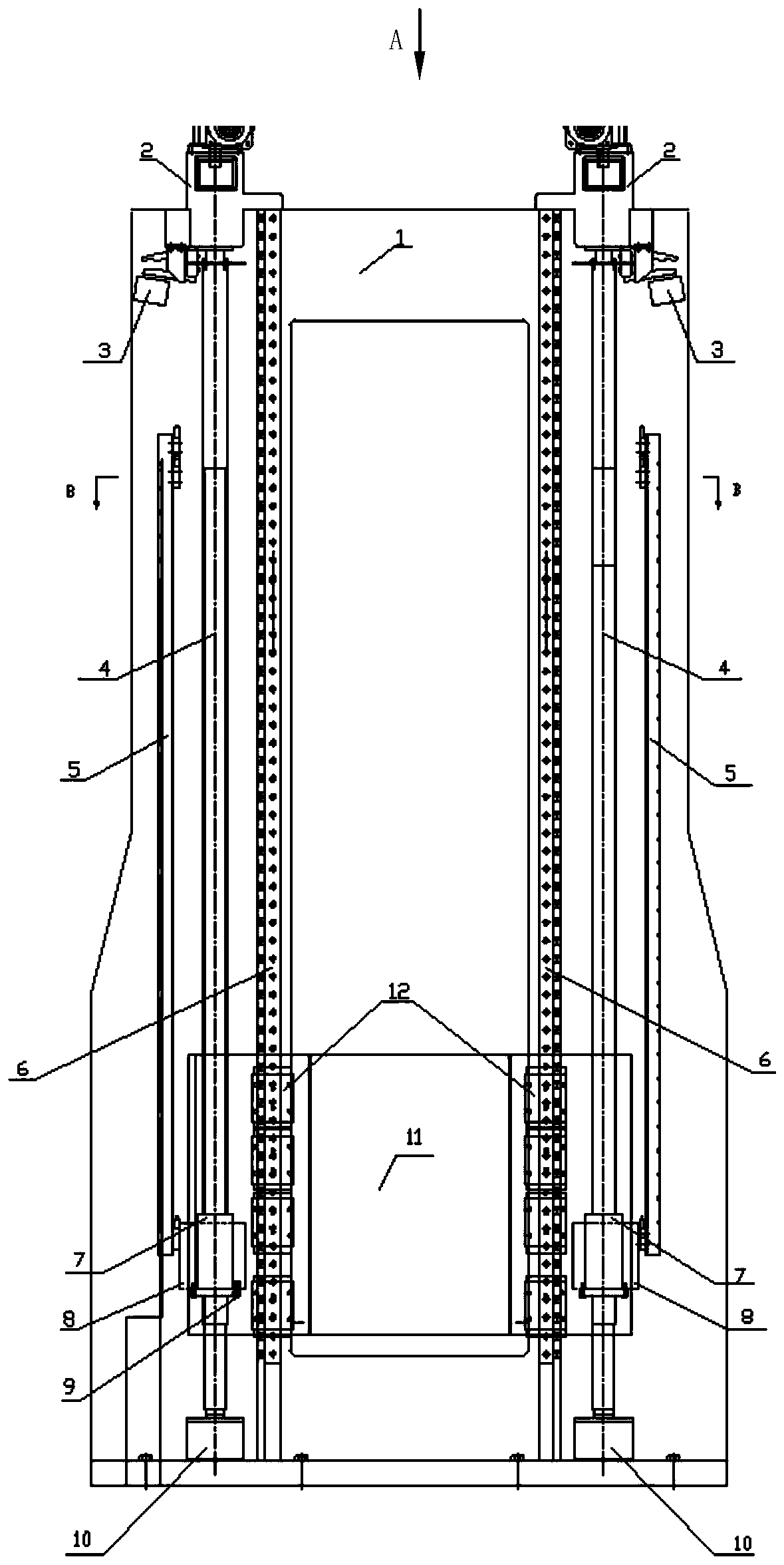

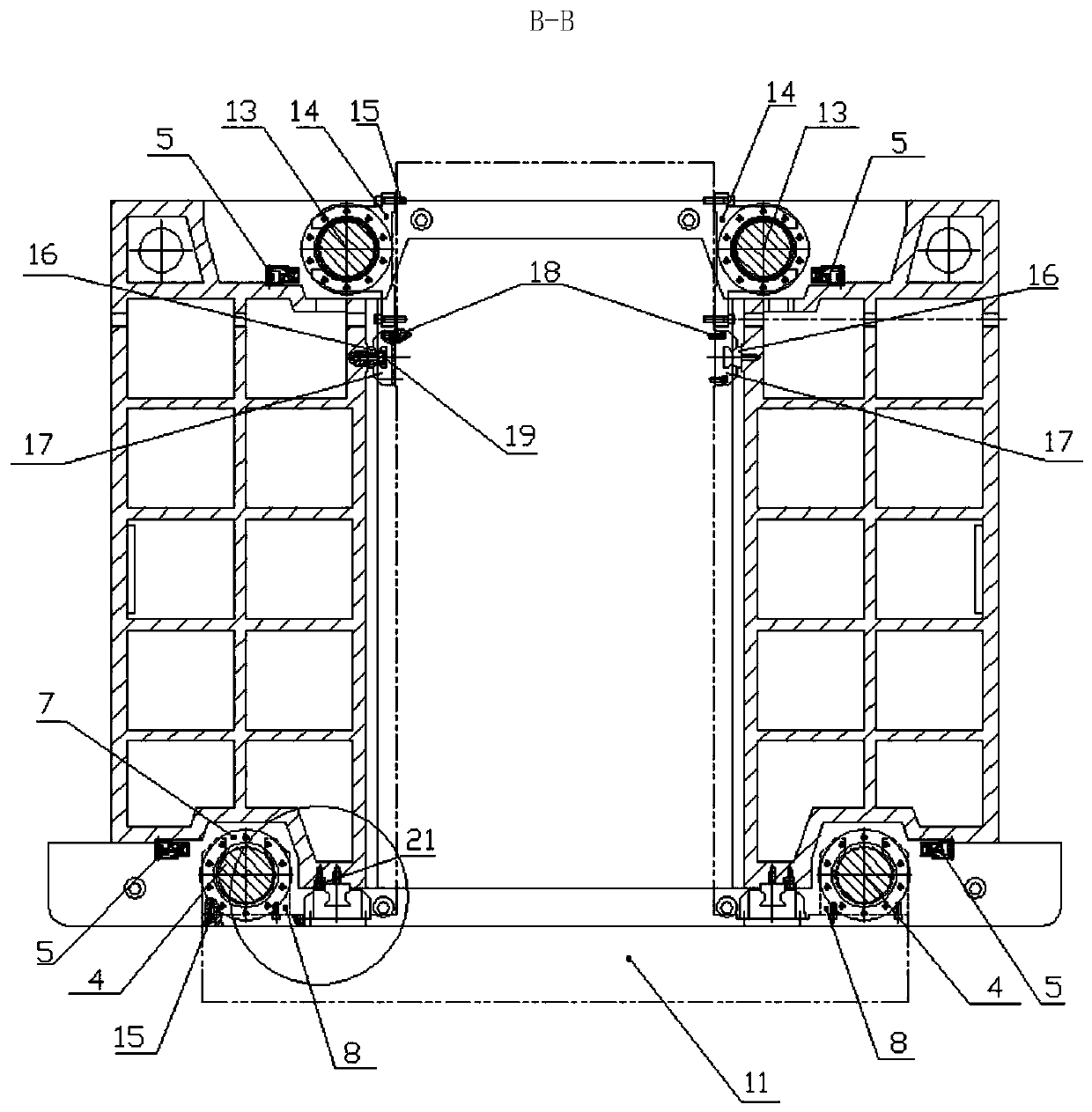

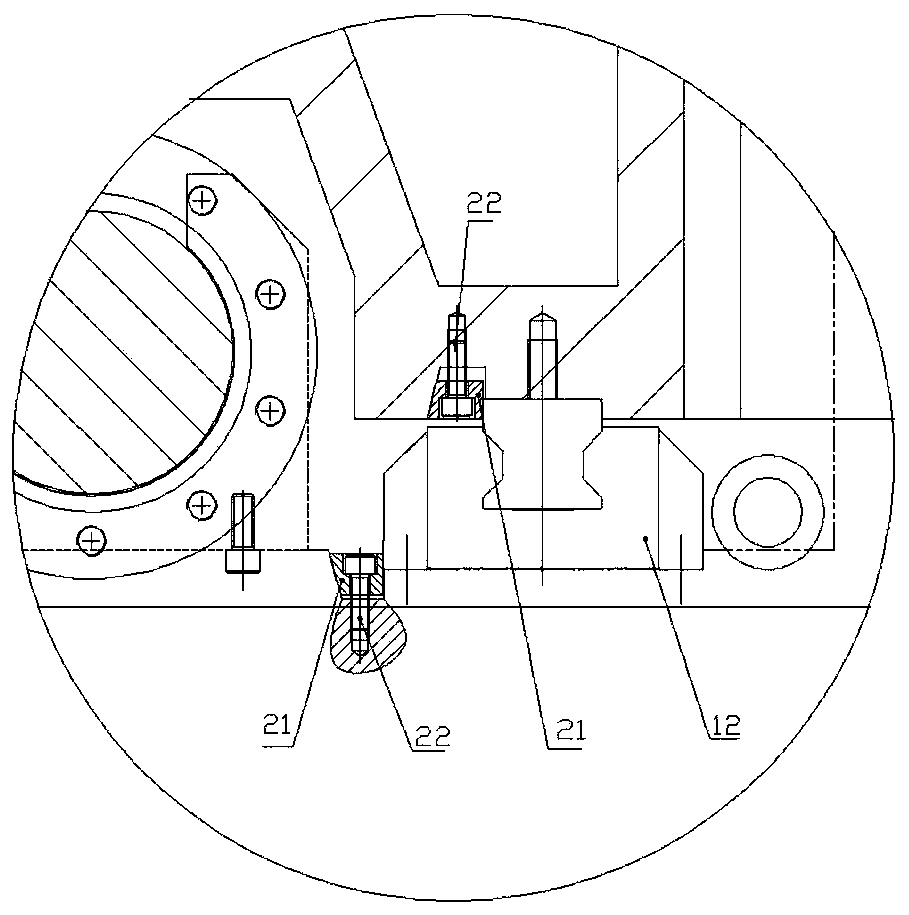

[0019] The four-screw drive system for the vertical axis of the CNC milling and boring machine mainly includes a machine tool electrical control system, four sets of screw drive structural units, four sets of vertical axis drive program units, and four sets of grating scale measurement systems. Hanging box structure, the following components: column, linear guide rail, grating ruler, upper motor seat, lower bearing seat, screw and screw nut, motor, reducer, etc., the structure of the entire drive system is shown in Figure 1~3 It is characterized in that the vertical section of the column 1 is a hollow-shaped, left-right symmetrical structure, placed vertically, two sets of front and rear screw drive systems with the same structure are respectively arranged in the front and rear of the column 1, and two sets of screw drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com