Rice fresh keeping, refrigerating and tempering system

A technology of rice and slowing down, applied in large containers, tankers, packaging, etc., can solve the problems of low integration, high investment cost, poor ability to adjust air humidity, etc., to achieve good energy saving effect, high degree of control, high precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described below with reference to specific examples. Those skilled in the art can understand that these examples are only used to illustrate the present invention and do not limit the scope of the present invention in any way.

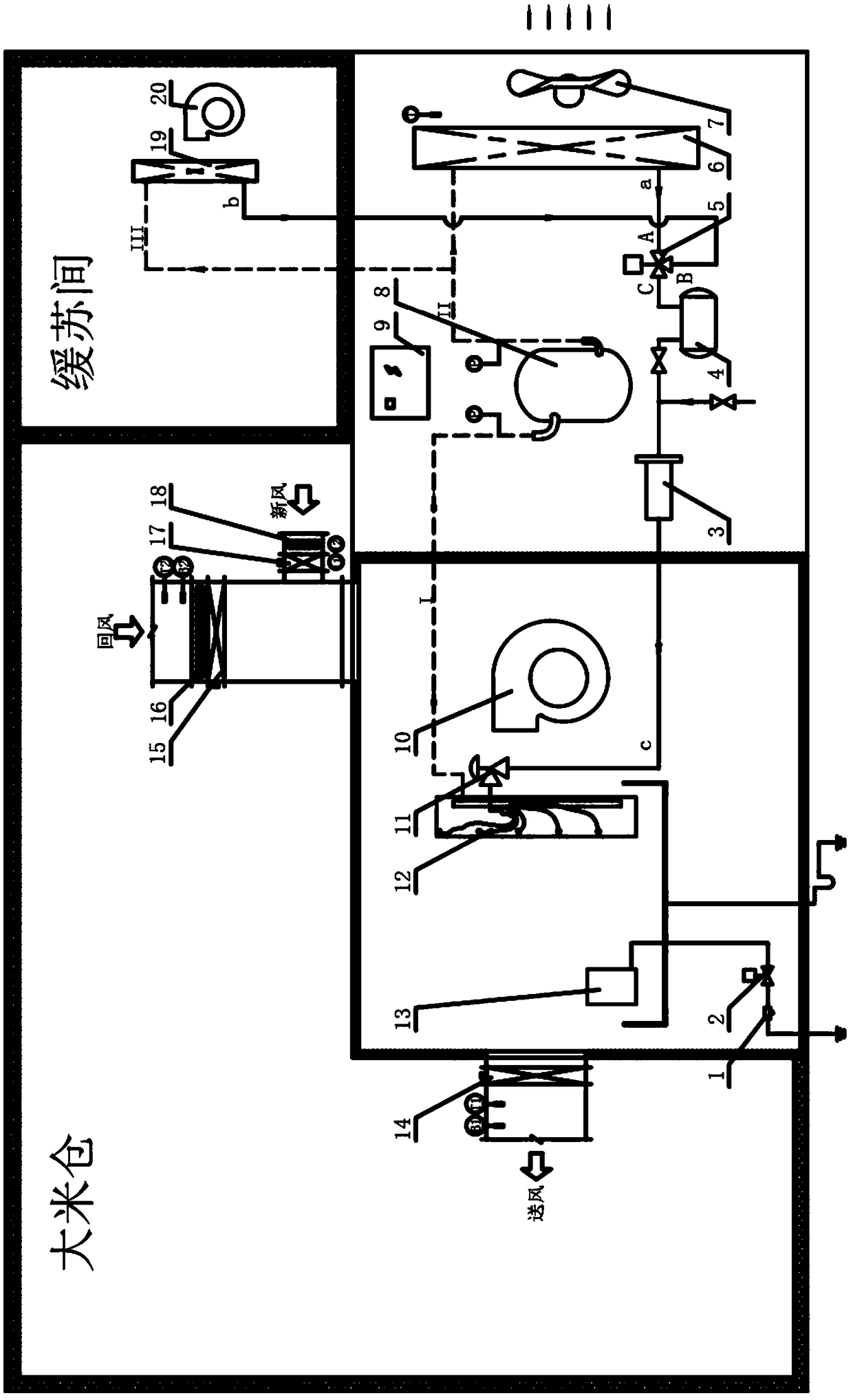

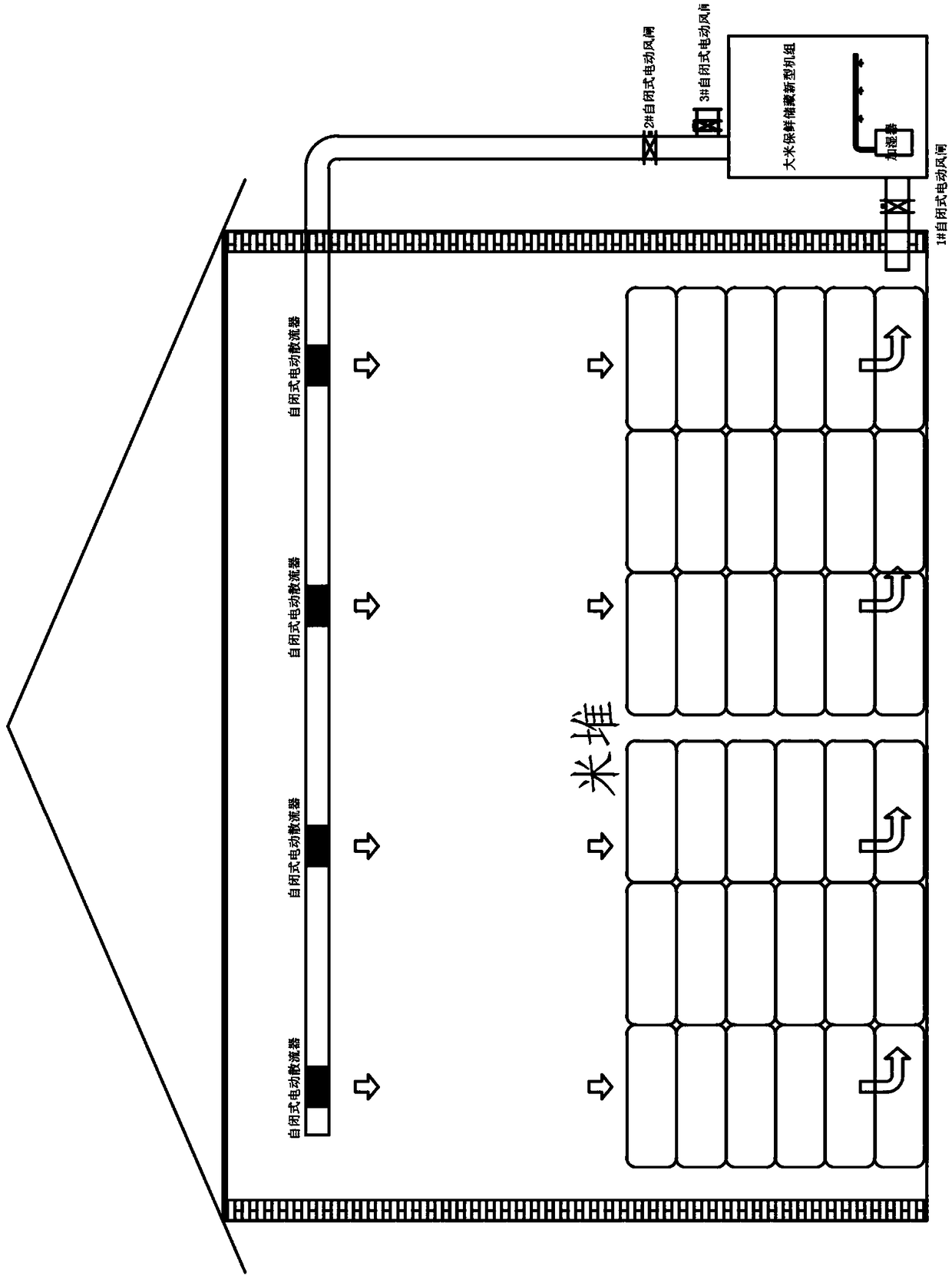

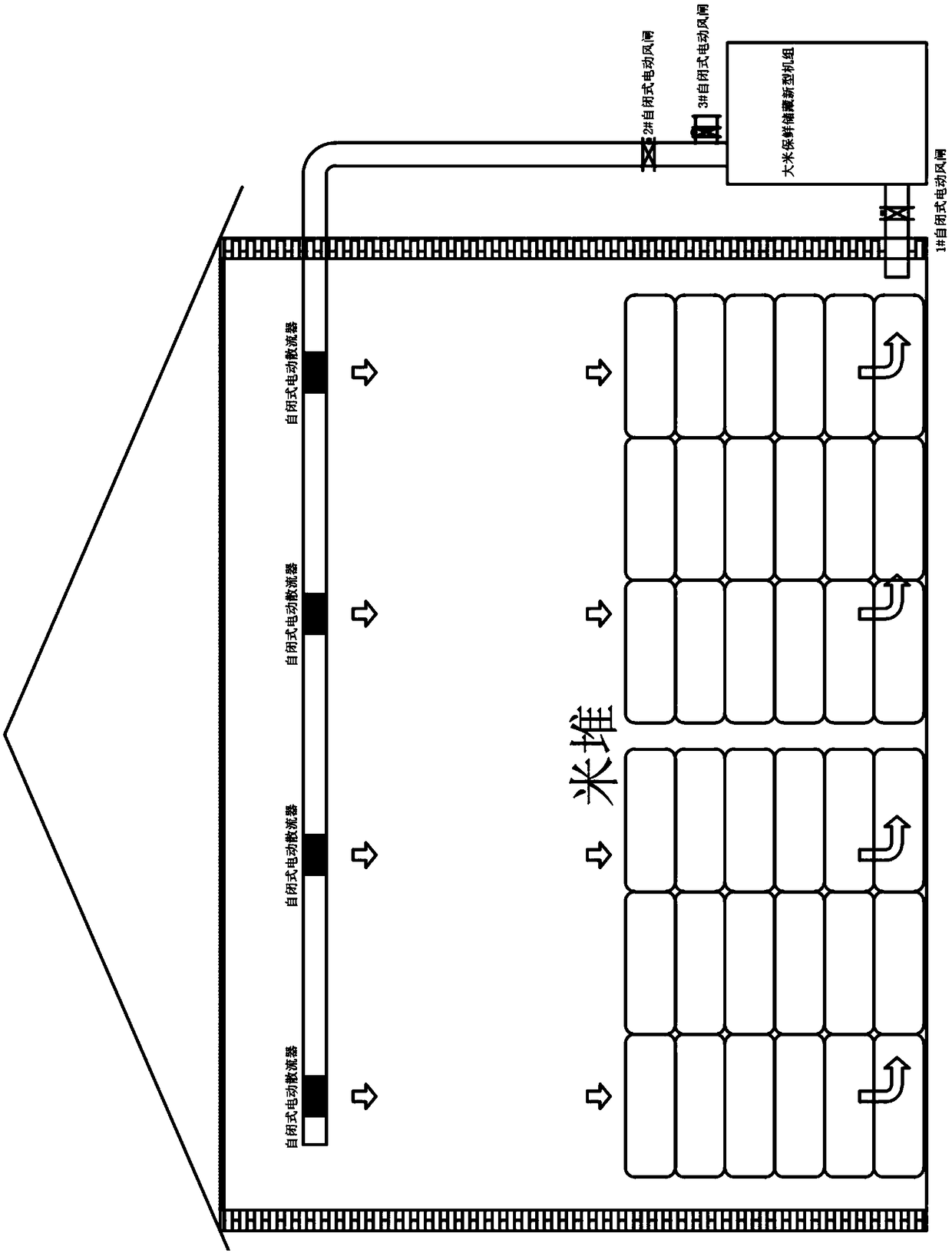

[0033] A new type of unit for rice preservation and storage is installed outside the granary, such as figure 1 As shown, including ultrasonic humidifier (13), evaporator (12), compressor (8), condenser (6), liquid receiver (4), dry filter (3) and various pipelines, also includes PLC electrical control box (9), ventilation mechanism and various sensors form humidification mechanism, heating mechanism, refrigeration circuit and ventilation mechanism:

[0034] (1) Humidification mechanism: including an ultrasonic humidifier (13) and two humidity sensors (B1, B2). The water inlet of the ultrasonic humidifier (13) is connected to the water supply port of the tap water pipeline, and there is a Y between them. Type water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com