Fully-automatic non-contact rail contour detecting device

A non-contact, contour detection technology, applied in the field of detection machines, can solve the problems that the detection equipment cannot meet the requirements of rail detection, low automation, and low detection accuracy, and achieves improved lateral movement accuracy, reduced labor intensity, and high detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

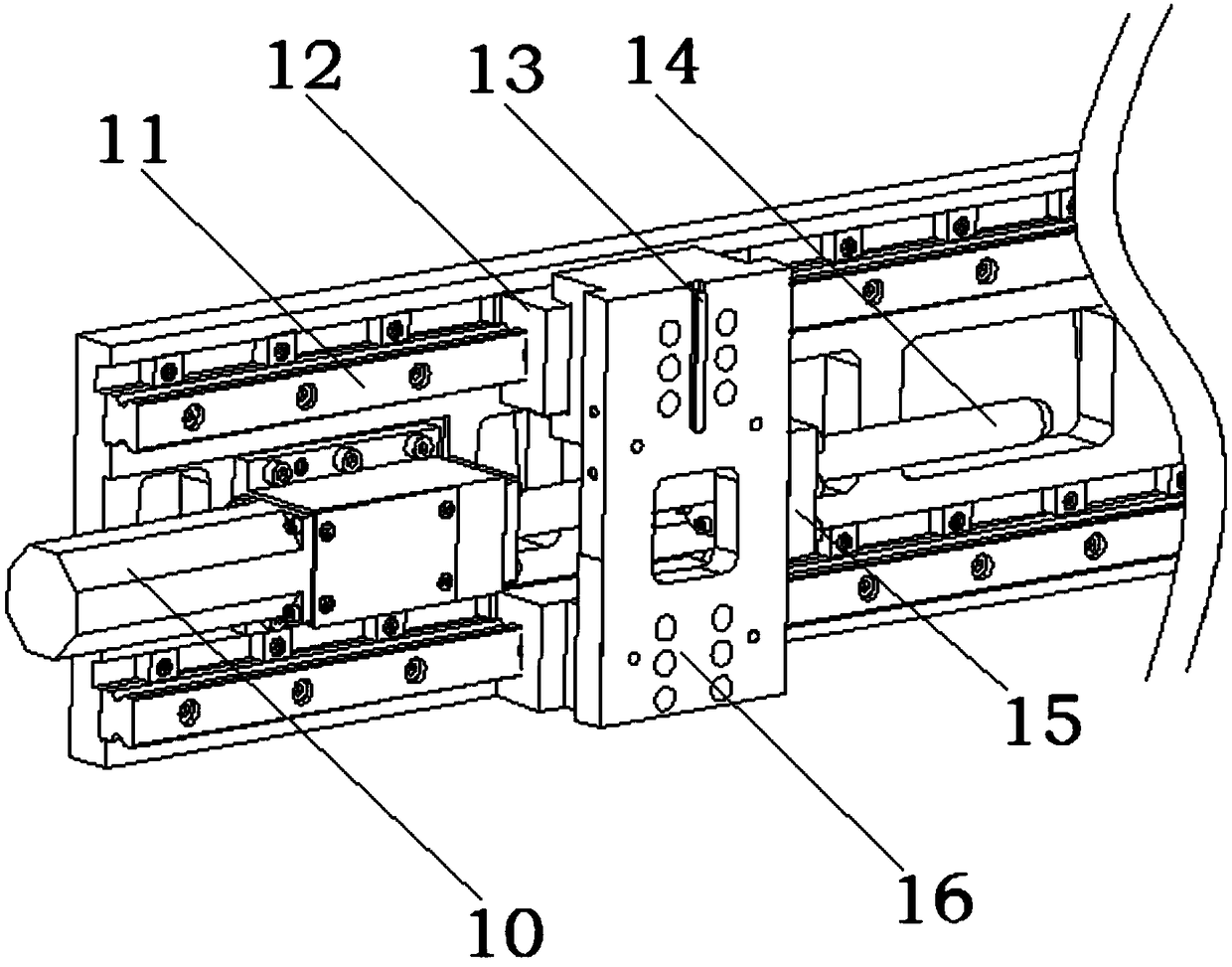

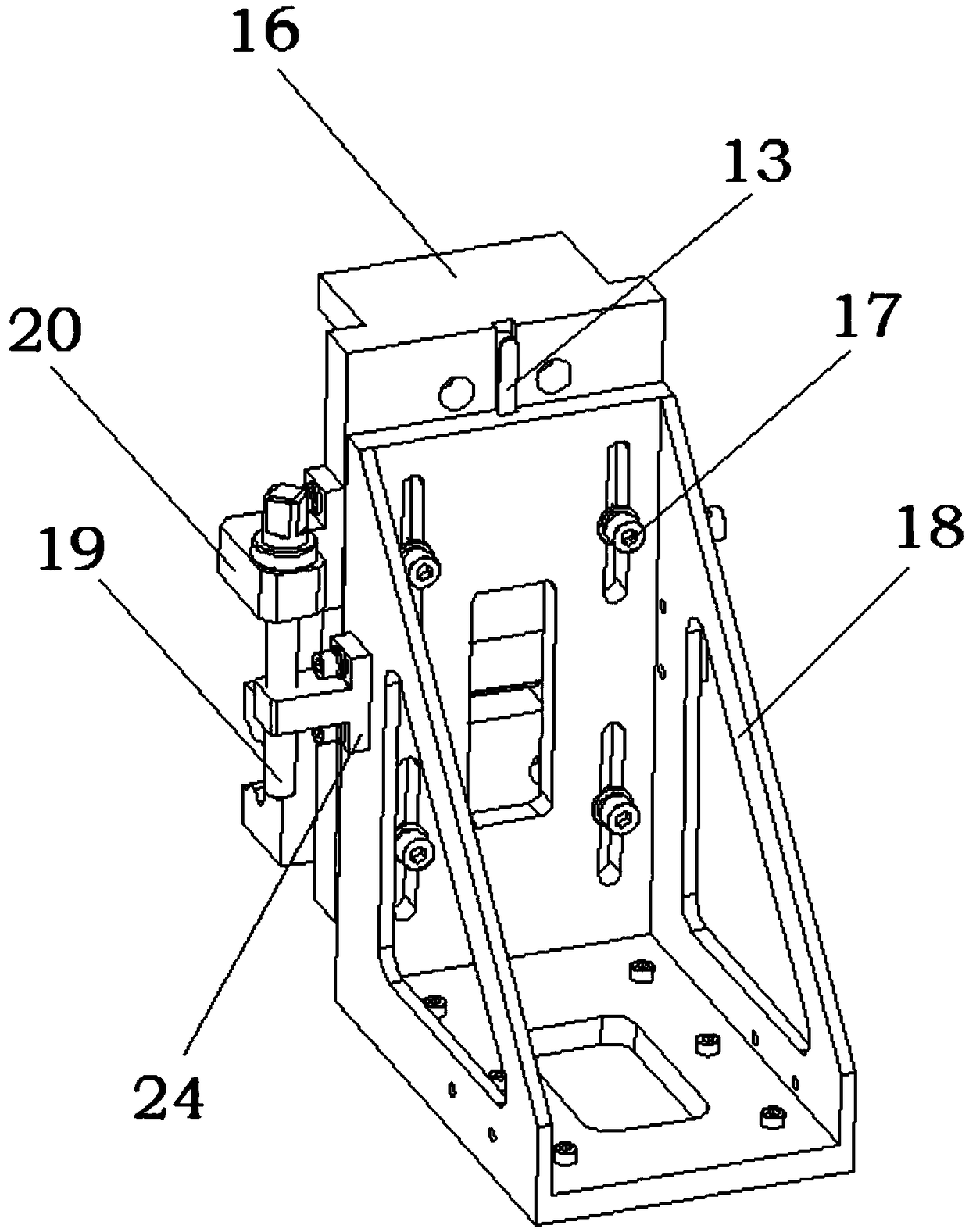

[0029] Such as Figure 1-5 As shown, the structure of the present invention is: a fully automatic rail non-contact profile detection device, including a base frame 1 and a fixing screw 8 that passes through the top surface of the base frame 1 and is installed to the bottom of the detection vehicle body, and the lower end of the base frame 1 is fixed Connect the crossbeam 3, two groups of lateral movement systems 4 are symmetrically arranged on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com