Multifunctional steel bar straightening device and method

A multi-functional, steel bar technology, applied in the field of metal processing and manufacturing, can solve the problems of poor straightening effect of steel bars, etc., and achieve stable rotation, stable operation, and good straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

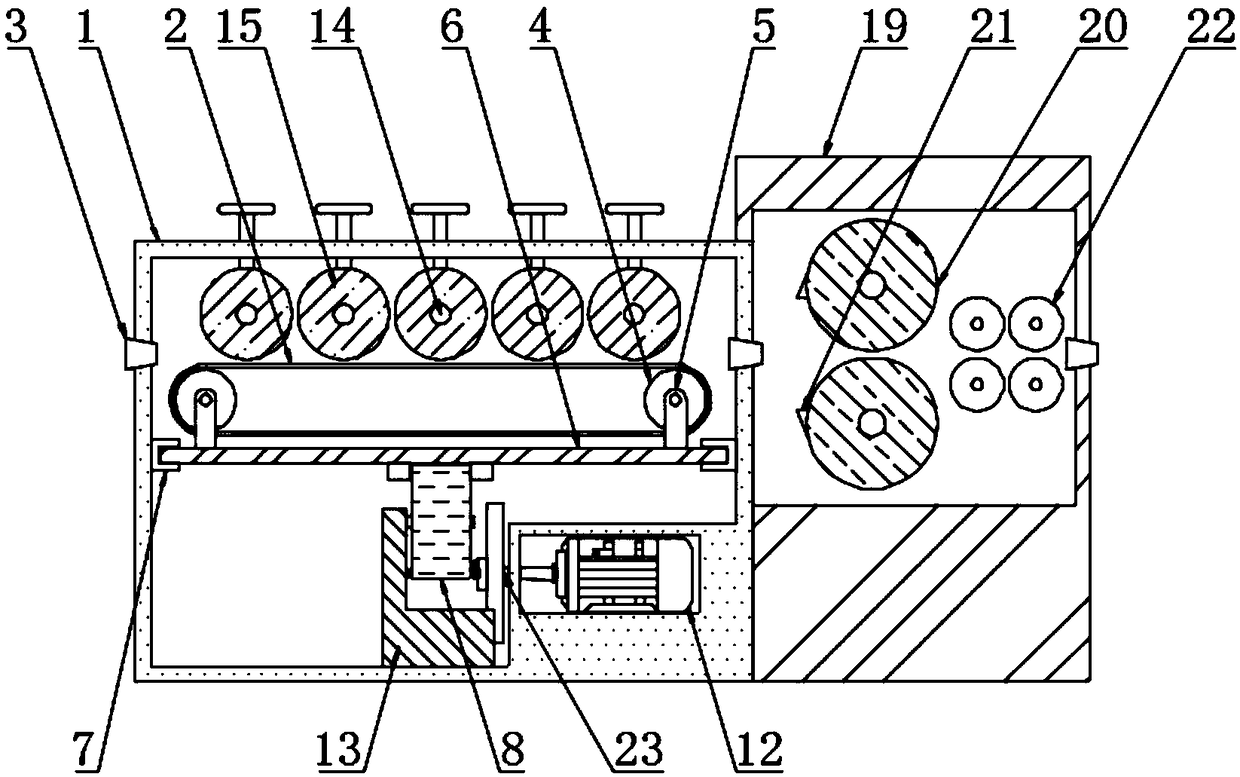

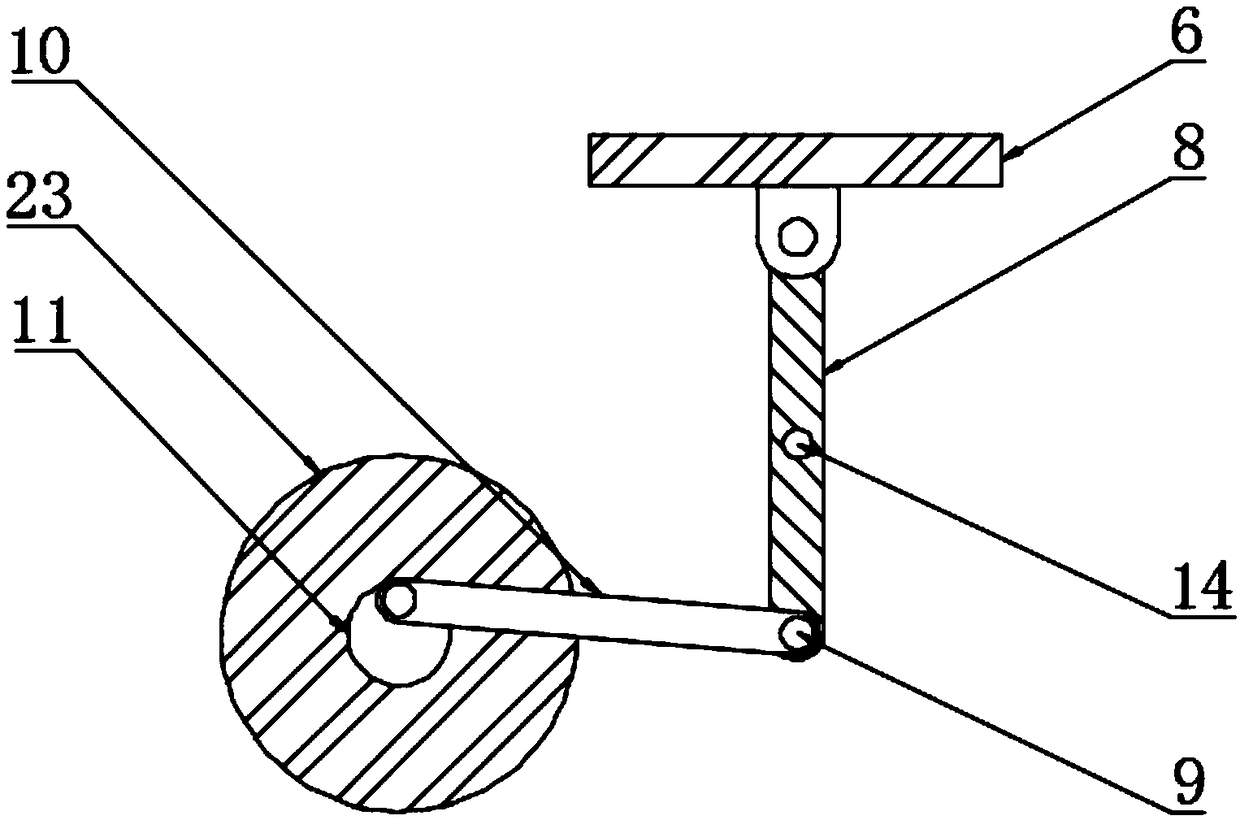

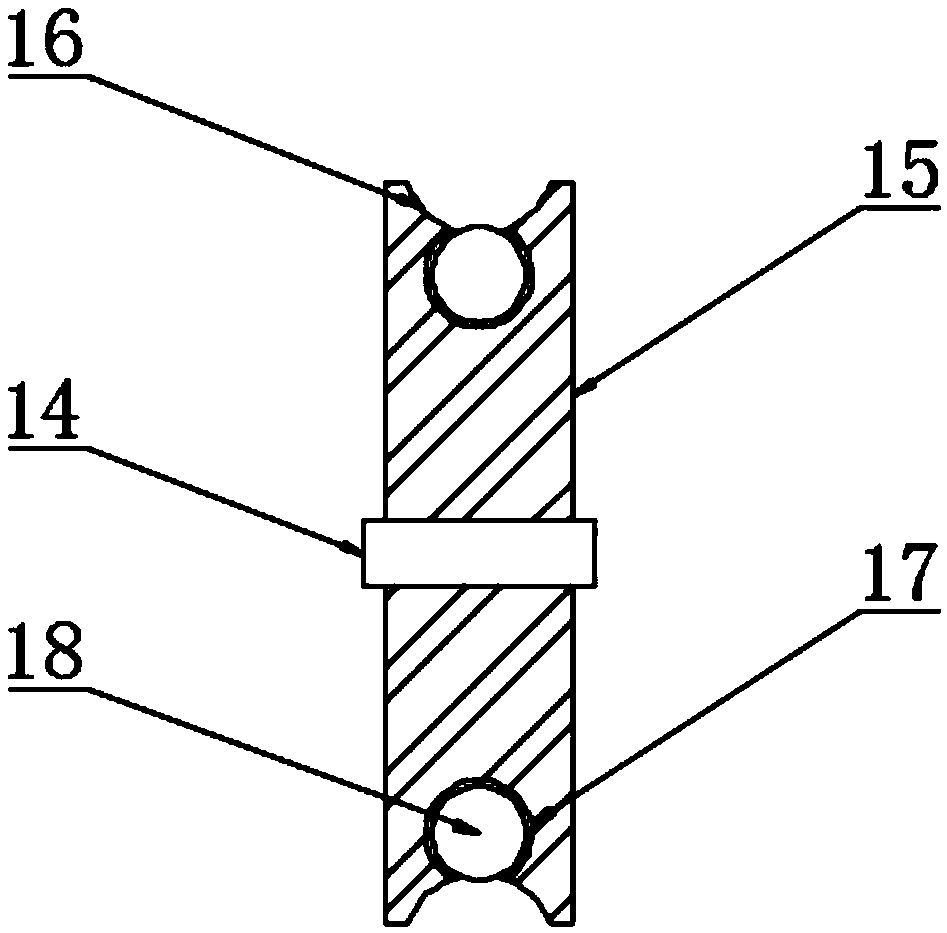

[0027] The present invention provides such Figure 1-3 The multifunctional steel bar straightening device shown includes a body 1, a traction belt 2 is arranged inside the body 1, positioning holes 3 are arranged on both sides of the traction belt 2, and a roller 4 is arranged inside the traction belt 2 , the two ends of the drum 4 are provided with a fixed frame 5, the bottom of the fixed frame 5 is provided with a movable plate 6, the two sides of the movable plate 6 are provided with chute 7, and the bottom of the movable plate 6 is provided with a linkage plate 8, The top of the linkage plate 8 is movably connected with the movable plate 6, the inside of the linkage plate 8 is provided with a shaft 9, the shaft 9 is fixedly connected with the linkage plate 8, and one end of the shaft 9 is provided with a transmission rod 10, and the transmission rod One end of 10 is provided with a runner 11, and one side of the runner 11 is provided with a motor 12, and the motor 12 is co...

Embodiment 2

[0037] A multifunctional steel bar straightening method, including the multifunctional steel bar straightening device, also includes the following steps:

[0038] S1: First, the steel bar is sent into the equipment through the positioning hole 3, and the steel bar is placed on the traction belt 2;

[0039] S2: Then the driving device drives the roller 4 to rotate between the fixed frames 5, and the rotation of the roller 4 drives the traction belt 2 to rotate, so that the steel bar moves forward continuously with the traction belt 2;

[0040] S3: The steel bar moves forward through the pressure roller 15, and when passing the pressure roller 15, the steel bar is pressed into the pressure groove 16, and the pressure wheel 15 straightens the steel bar;

[0041] S4: When the steel bar passes through the pressure wheel 15, the motor 12 drives the runner 11 to rotate, and by connecting the runner 11 and the linkage plate 8 to the transmission rod 10, the linkage plate 8 is fixed ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com