Efficient froth can

A foam and high-efficiency technology, applied in the field of foam pots, can solve the problems of inconspicuous foam, low efficiency, and long air intake channels, and achieve an obvious mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

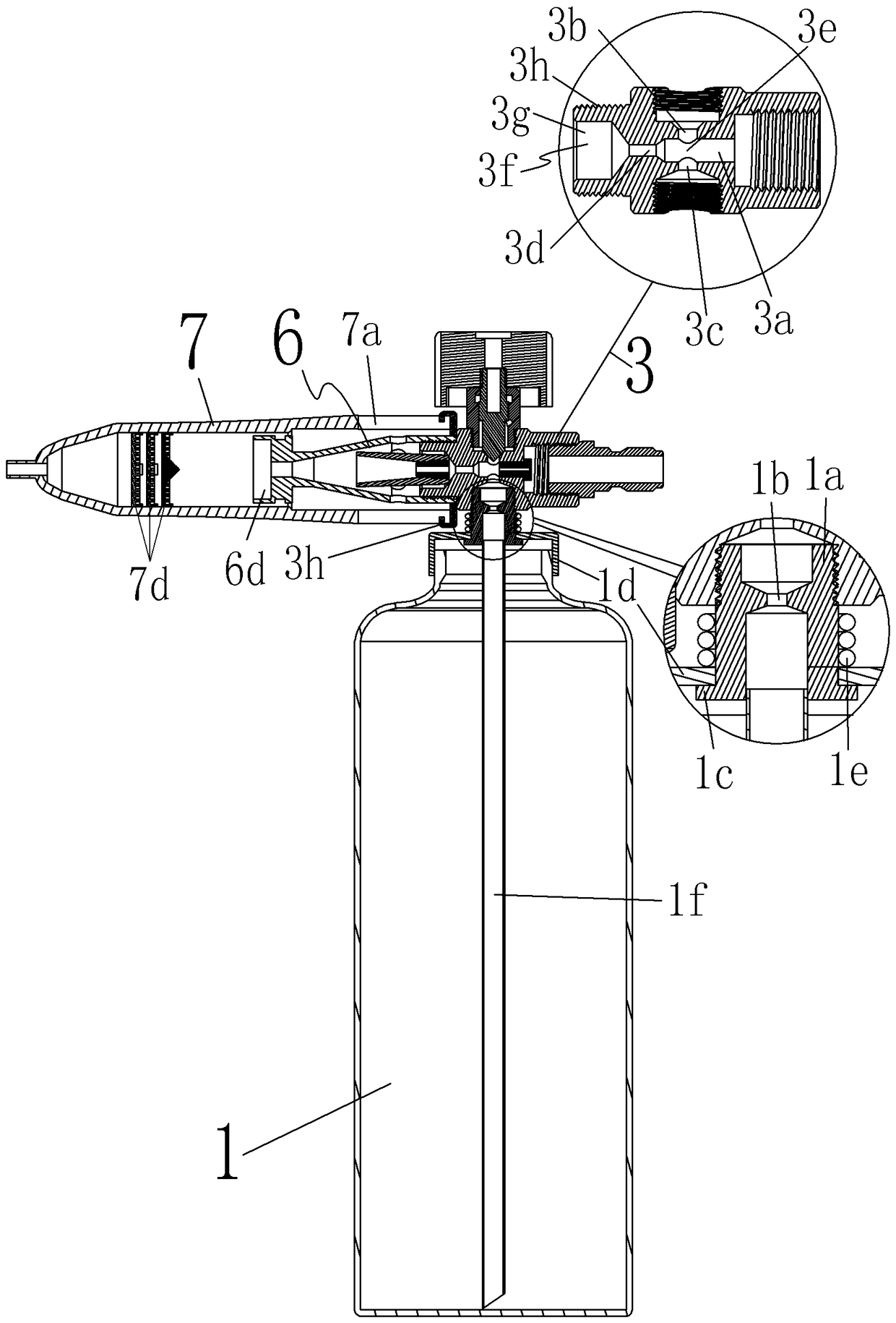

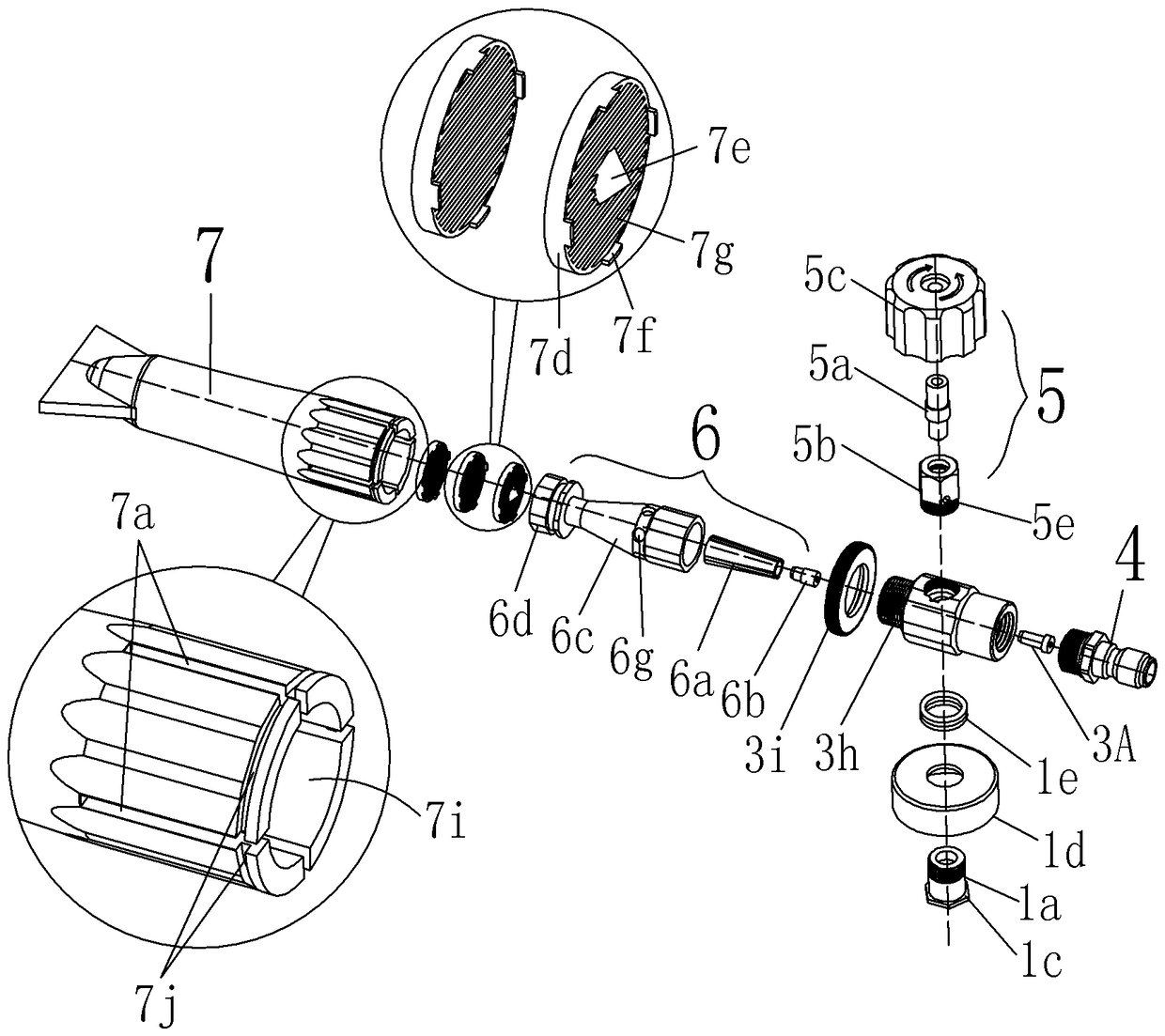

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

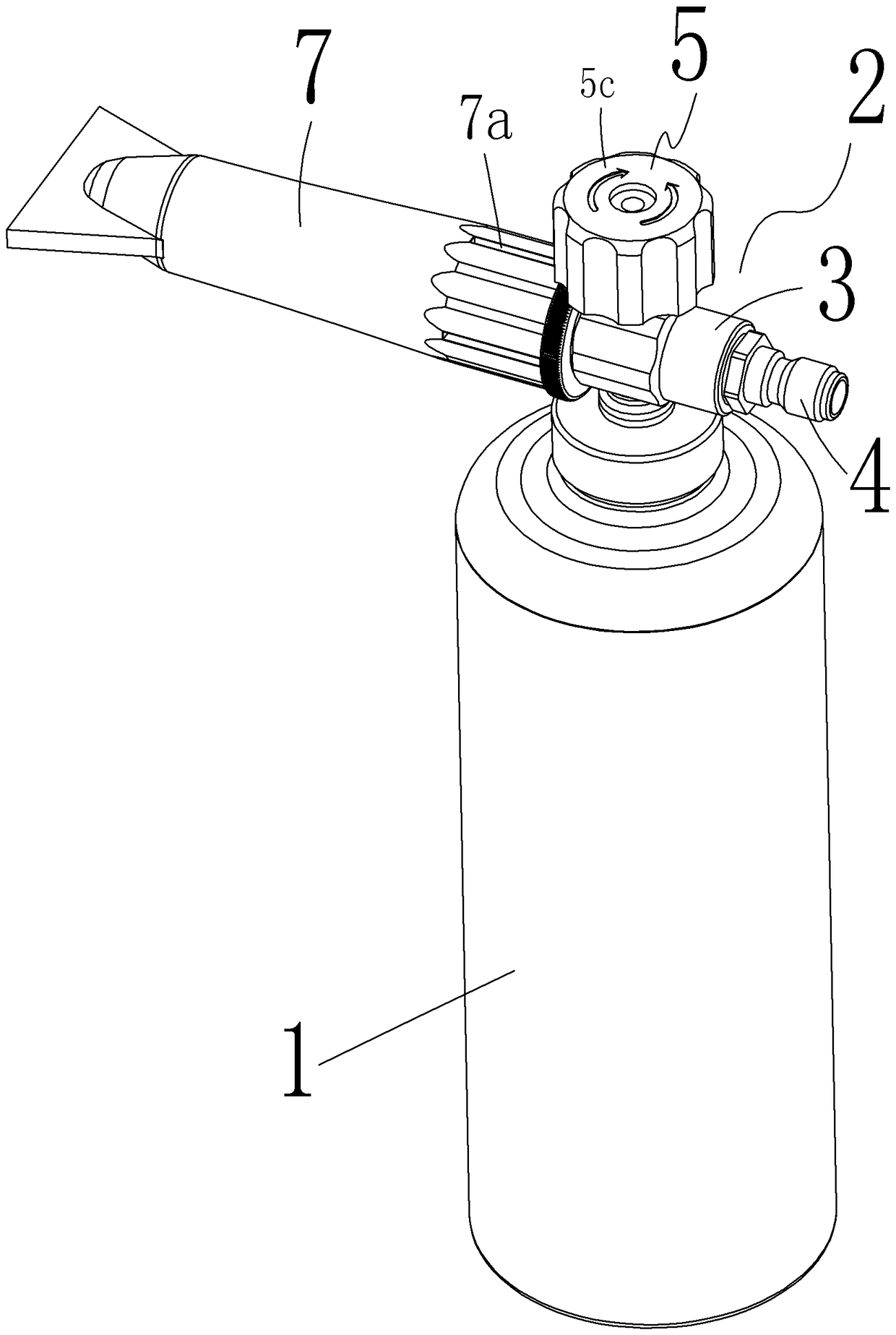

[0022] refer to Figure 1 to Figure 5 , a high-efficiency foam pot, comprising a liquid storage bottle 1, a bubble spray gun 2 installed above the liquid storage bottle 1; The holster consists of 7;

[0023] The gun core body 3 is provided with a pressure inlet hole 3a, a volume adjustment hole 3b, a liquid suction hole 3c and a nozzle hole 3d. The pressure inlet hole 3a, the volume adjustment hole 3b, the liquid suction hole 3c and the nozzle hole 3d have an intercommunication area in the gun core body 3. When the high pressure pump provides high pressure water III and enters the intercommunication area through the high pressure pump and the pump 4, According to the Venturi effect, a negative pressure is formed in the communication area, so that the adjustment hole 3b and the liquid suction hole 3c enter the air and liquid into the communication area, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com