Method for sodium alginate microsphere adsorbent through emulsion polymerization process

A technology of emulsion polymerization and sodium alginate, which is applied in the field of preparation of porous adsorbents, can solve the problems of difficult application of emulsion polymerization and preparation of sodium alginate microspheres, etc., and achieves high adsorption capacity, good industrial application prospects, and is not easy to short circuit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) First, mix 10 mL of carbon disulfide and 250 mL of 14% sodium hydroxide solution, then add 5 g of sodium alginate, and keep stirring at 30° C. for 24 hours.

[0023] (2) The obtained solution was mixed with 6 g of calcium carbonate powder, and stirred at 400 rpm for 15 min with an electric stirrer. Then add 100mL paraffin oil and 2mL Span 85 emulsifier, and continue stirring for 20min.

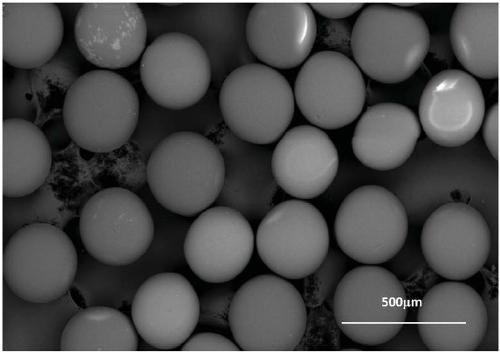

[0024] (3) Add 10 mL of glacial acetic acid to the prepared emulsion, and keep stirring for 30 min at a rotating speed. Finally, 200 mL of deionized water was added and allowed to stand for 24 h. The obtained microspherical solid is washed repeatedly with ethanol and deionized water to obtain the microspherical adsorbent of sodium alginate as raw material (its scanning electron microscope picture is as follows: figure 1 shown).

Embodiment 2

[0026] (1) First, mix 10 mL of carbon disulfide and 250 mL of 14% sodium hydroxide solution, then add 8 g of sodium alginate, and keep stirring at 30° C. for 24 hours.

[0027] (2) The obtained solution was mixed with 8 g of calcium carbonate powder, and stirred at 600 rpm for 15 min with an electric stirrer. Then add 100mL paraffin oil and 3mL Span 85 emulsifier, and continue stirring for 20min.

[0028] (3) Add 15 mL of glacial acetic acid to the prepared emulsion, and keep stirring for 30 min at a rotating speed. Finally, 200 mL of deionized water was added and allowed to stand for 24 h. The obtained microspherical solid is repeatedly washed with ethanol and deionized water to obtain the microspherical adsorbent with sodium alginate as the raw material.

Embodiment 3

[0030] (1) First, mix 10 mL of carbon disulfide and 250 mL of 14% sodium hydroxide solution, then add 10 g of sodium alginate, and keep stirring at 30° C. for 24 hours.

[0031] (2) Mix the obtained solution with 10 g of calcium carbonate powder, and stir for 15 min at 800 rpm with an electric stirrer. Then add 100mL paraffin oil and 4mL Span 85 emulsifier, and continue stirring for 20min.

[0032] (3) Add 15 mL of glacial acetic acid to the prepared emulsion, and keep stirring for 30 min at a rotating speed. Finally, 200 mL of deionized water was added and allowed to stand for 24 h. The obtained microspherical solid is repeatedly washed with ethanol and deionized water to obtain the microspherical adsorbent with sodium alginate as the raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com