Zinc sulfide/porous carbon nano-fiber composite material and preparation method thereof

A technology of nanofibers and composite materials, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor material structure stability, limited application of composite materials, high requirements for process equipment, etc., to achieve inhibition Effect of agglomeration, improvement of cycle stability, and mitigation of volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

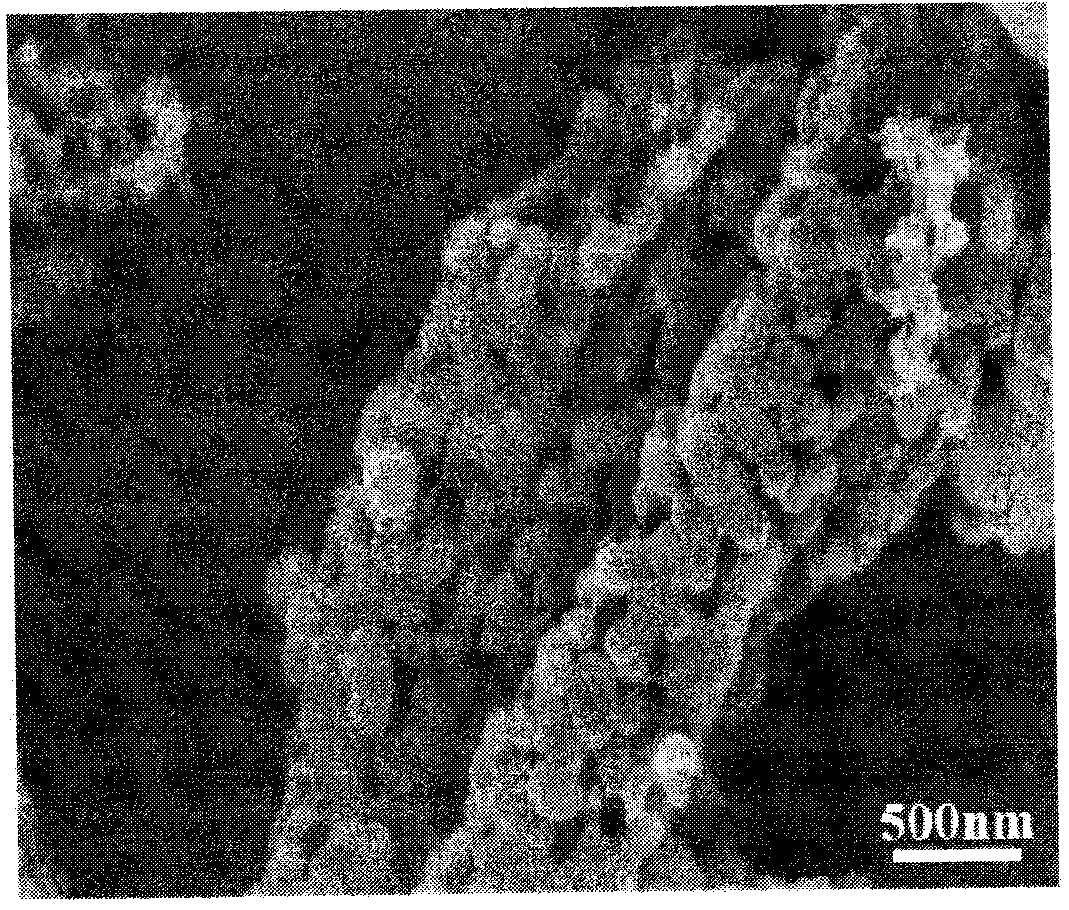

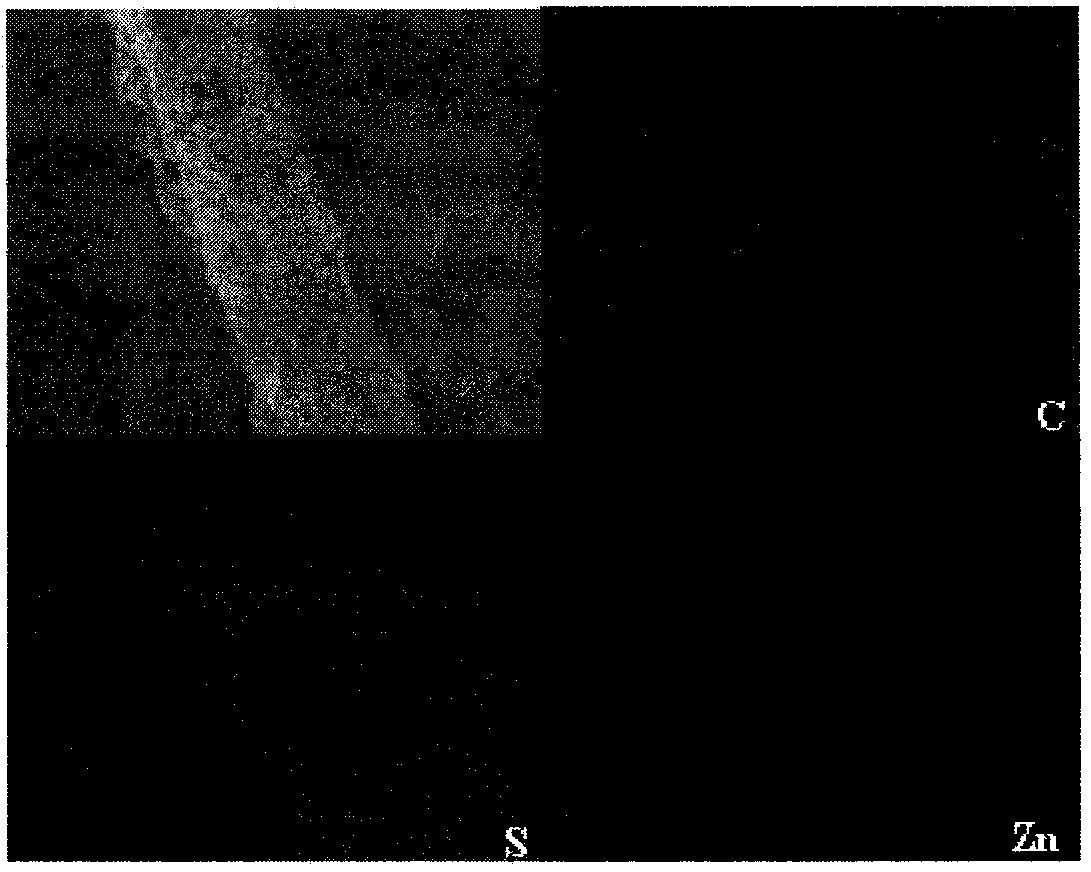

Image

Examples

Embodiment 1

[0020] (1) The present invention is first based on the invention patent that our research group has applied for: a porous carbon nanofiber membrane for lithium-sulfur battery positive electrode material and its preparation method (CN105161722A), and polytetrafluoroethylene aqueous emulsion, polyvinyl alcohol Solution and boric acid solution were blended to prepare spinning solution, and polyvinyl alcohol / polyvinylidene fluoride nanofibers were prepared by electrostatic melt blowing method. preoxidation treatment to obtain preoxidized polyvinyl alcohol / polyvinylidene fluoride nanofibers.

[0021] (2) Dissolve 7mmol of zinc acetate and 14mmol of thiourea in 70mL of ethylene glycol, then add 8.4g of pre-oxidized fibers for ultrasonic dispersion for 30min, then transfer to a reactor, and react at 160°C for 12h. After centrifugal washing and drying at 60°C for 12 hours, preoxidized polyvinyl alcohol / polyvinylidene fluoride nanofibers loaded with zinc sulfide precursor were obtained...

Embodiment 2

[0024] (1) The present invention is first based on the invention patent that our research group has applied for: a porous carbon nanofiber membrane for lithium-sulfur battery positive electrode material and its preparation method (CN105161722A), and polytetrafluoroethylene aqueous emulsion, polyvinyl alcohol Solution and boric acid solution were blended to prepare spinning solution, and polyvinyl alcohol / polyvinylidene fluoride nanofibers were prepared by electrostatic melt-blowing method. preoxidation treatment to obtain preoxidized polyvinyl alcohol / polyvinylidene fluoride nanofibers.

[0025](2) Dissolve 7mmol of zinc nitrate and 14mmol of thioacetamide in 70mL of distilled water, then add 16.8g of pre-oxidized fibers for ultrasonic dispersion for 60min, then transfer to a reactor, and react at 80°C for 6h. After centrifugal washing and drying at 60°C for 12 hours, preoxidized polyvinyl alcohol / polyvinylidene fluoride nanofibers loaded with zinc sulfide precursor were obtai...

Embodiment 3

[0028] (1) The present invention is first based on the invention patent that our research group has applied for: a porous carbon nanofiber membrane for lithium-sulfur battery positive electrode material and its preparation method (CN105161722A), and polytetrafluoroethylene aqueous emulsion, polyethylene Alcohol solution and boric acid solution were blended to prepare spinning solution, and polyvinyl alcohol / polyvinylidene fluoride nanofibers were prepared by electrostatic solution blowing method. In the air atmosphere, the temperature was raised to 300°C at a rate of 2°C / min and kept for 3h for nanofibers. Perform pre-oxidation treatment to obtain pre-oxidized polyvinyl alcohol / polyvinylidene fluoride nanofibers.

[0029] (2) Dissolve 7mmol of zinc sulfide and 14mmol of thiourea in 70mL of ethanol, then add 4.2g of pre-oxidized fibers for ultrasonic dispersion for 60min, then transfer to the reactor, and react at 70°C for 6h. After centrifugal washing and drying at 50°C for 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com