Engineering Drawing Method of Rolling Bearing Based on VB

A technology of engineering drawing and rolling bearing, applied in the field of drawing, can solve the problems of heavy workload, high error rate, and time-consuming electronic drawing, and achieve the effect of improving design efficiency, reducing error rate, and having traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] The engineering drawing method of the rolling bearing based on VB of the present embodiment, as Figure 12 As shown, the described method is realized through the following steps:

[0037] Step 1. Establish a standard drawing database of bearing parts;

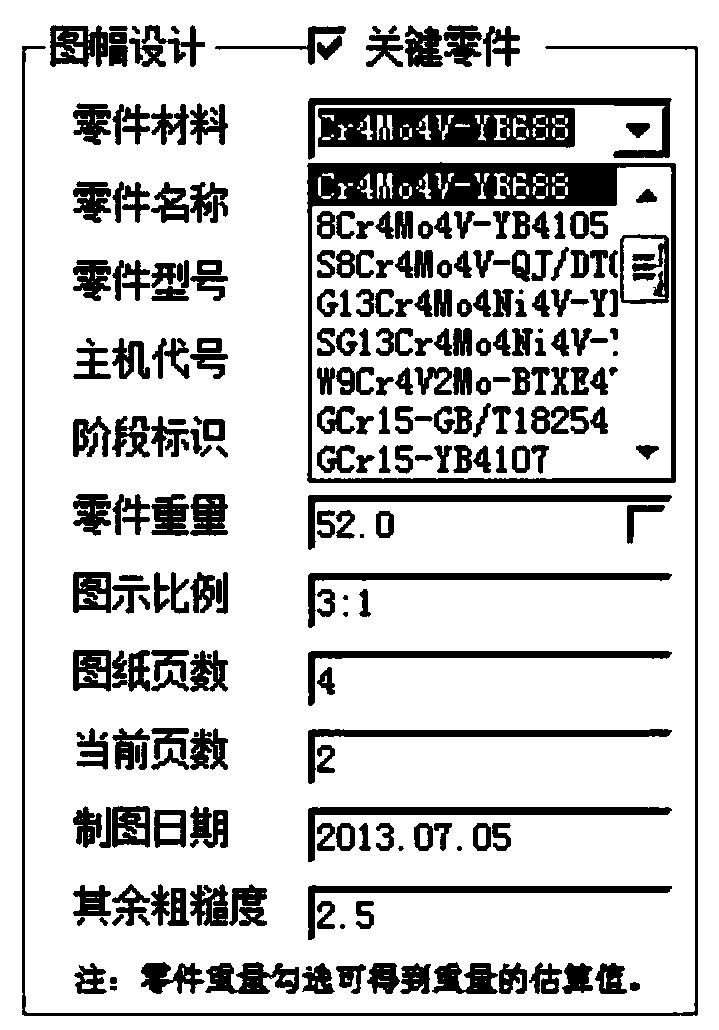

[0038] First, draw the standard drawing template of bearing parts, including: outer ring, inner ring, rolling element, cage, assembly drawing; then, use the container function of VB software to embed the standard drawing template of bearing parts into the data layer of VB software , to form a standard map frame database; finally, set the command button control for calling the standard map frame template, and complete the design process of the bearing standard map frame database;

[0039] Step 2. Query the design process of the bearing accuracy function;

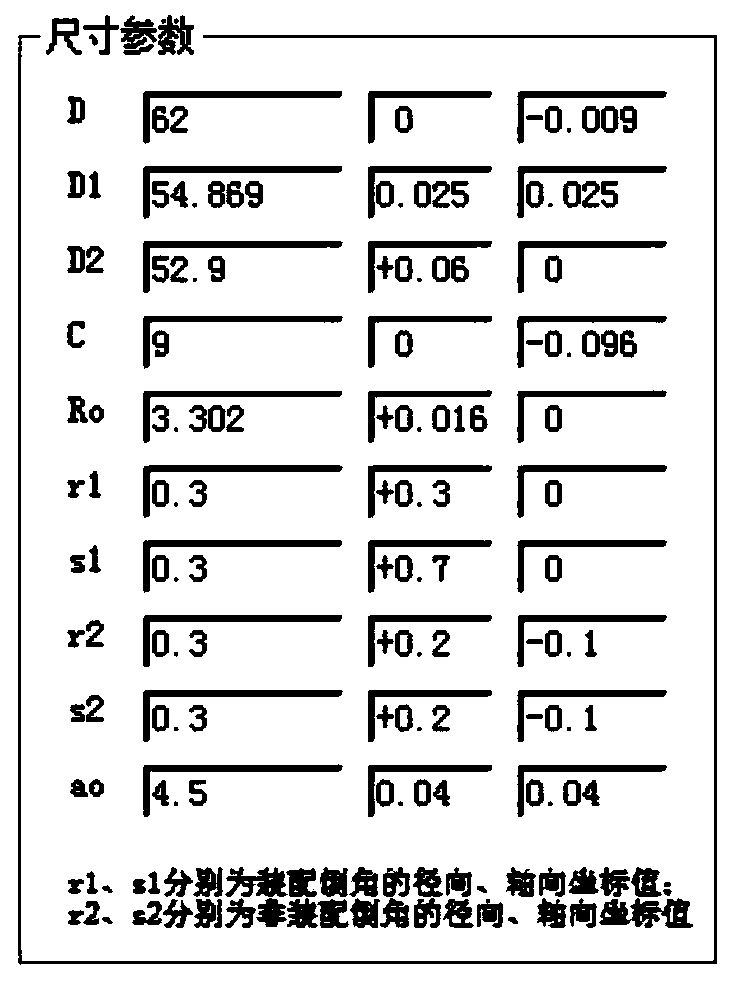

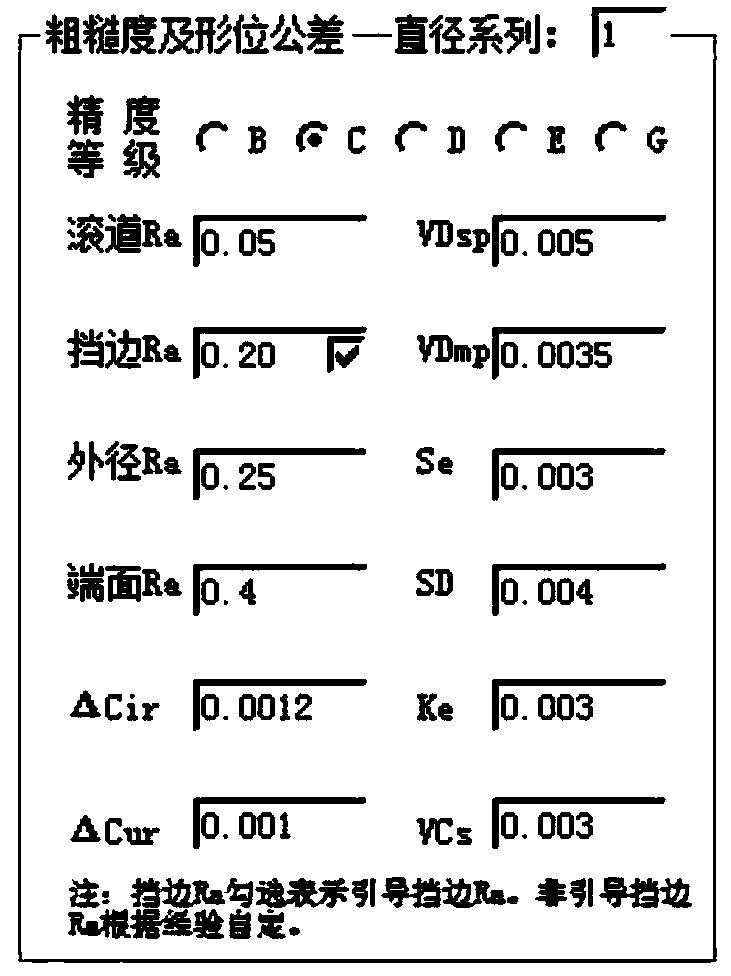

[0040] Different from the traditional bearing precision design method that uses look-up table selection, the present invention creates the bearing parts precision dat...

specific Embodiment approach 2

[0053] The difference from the first embodiment is that in the VB-based rolling bearing engineering drawing method of this embodiment, the command button control of the VB software described in step three calls the AutoCAD software to draw the engineering drawing of the two-dimensional structure of the bearing. The drawing process of the two-dimensional structure follows the drawing sequence of forming a line from a point and forming a surface from a line. Specifically, determine the two end points of the drawn line, then use the VB command to draw a line, and then connect the end points of the line to complete the bearing part Structure drawing.

specific Embodiment approach 3

[0054]The difference from specific embodiment 1 or 2 is that the VB-based engineering drawing method for rolling bearings in this embodiment also includes a design process for querying the function of bearing roughness, specifically: After the design process of querying the bearing accuracy function in step 2, create the bearing roughness database through VB software, and set the command button control for calling the bearing roughness database. During the drawing process, input the basic dimensions of the bearing, that is, quickly call the bearing roughness The database realizes the automatic query function of bearing roughness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com