A method for automatically calibrating platform position coordinates

A technology of position coordinates and automatic calibration, applied in the field of medical equipment, can solve the problems of consuming a lot of human resources, inaccurate positioning and affecting the normal operation of equipment, etc., to improve work efficiency and equipment accuracy, reduce workload, and achieve accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

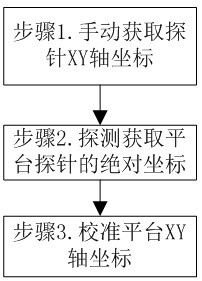

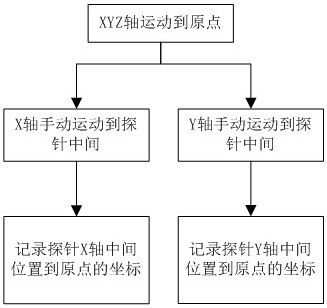

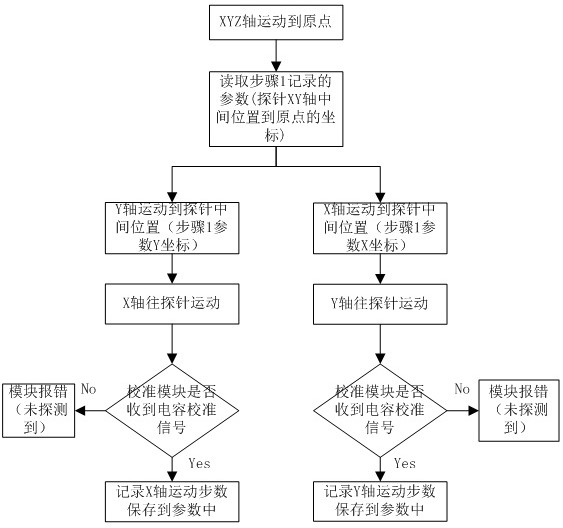

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, in a specific embodiment of the present invention, it is assumed that the actual coordinate value of the X-axis is X1, and the absolute coordinate value of the X-axis is X0; the actual coordinate value of the Y-axis is Y1, and the absolute coordinate value of the Y-axis is Y0; X1-X0=S1; Y1-Y0=S2;, the deviation tolerance value is φ, and the calibration method includes the following steps.

[0022] A method for automatically calibrating platform position coordinates according to the present invention is realized by a calibration module, which is independent from other modules on the platform and includes a capacitance detection pin, a capacitance pole and a PCB, wherein the capacitance pole includes a connection with the detection pin The conductive metal block and the metal structure in the Z-axis direction, wherein the detection pin and the conductive metal block are connected through the PCB, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com