Quick inspection tooling and inspection method for installation and completion of cargo tank adjusting pad

A fast technology for adjusting pads, applied in the direction of mechanical clearance measurement, etc., can solve the problems of affecting the installation cycle of cargo tanks, wasting precious time of shipowners, affecting the progress of tank piping and oil stringing, and shortening the time for inspection , simple structure, and the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

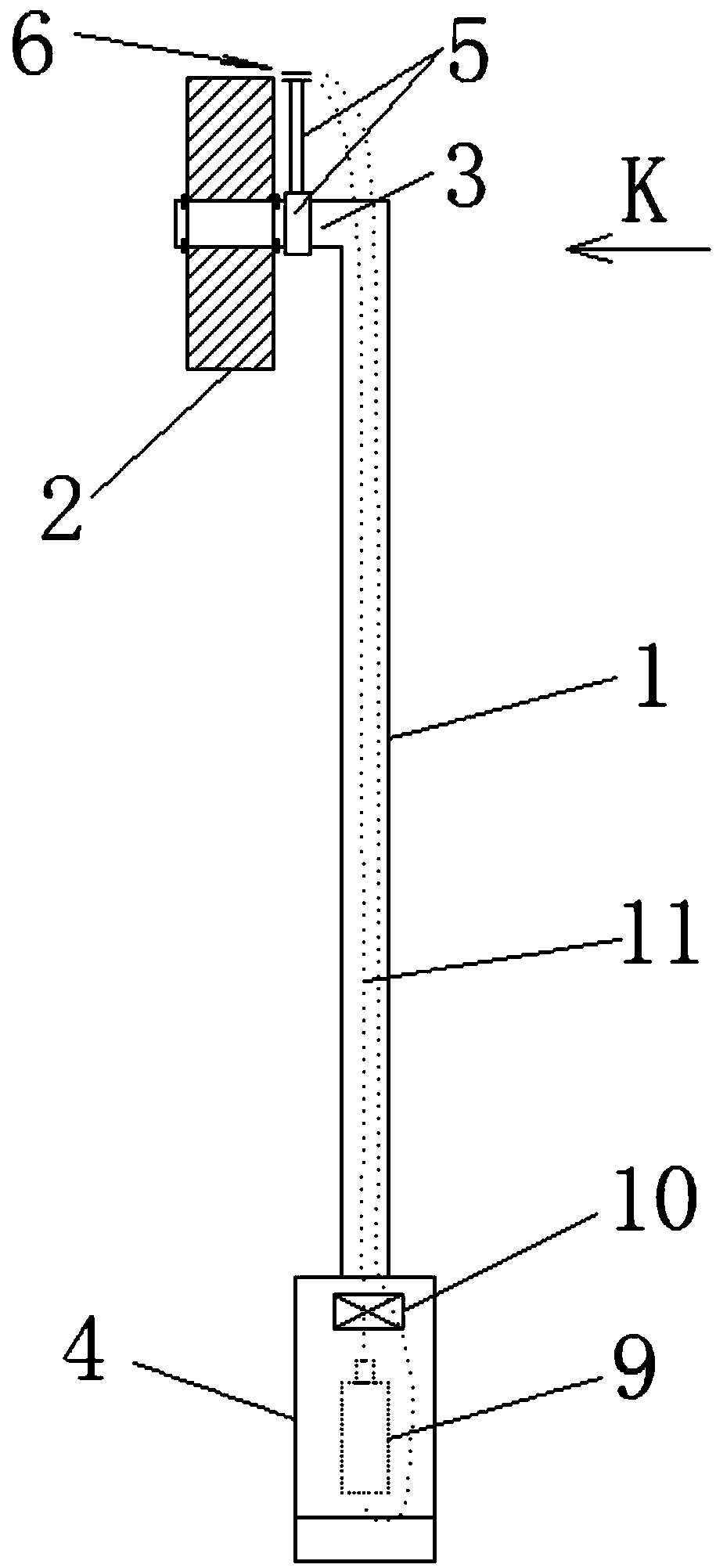

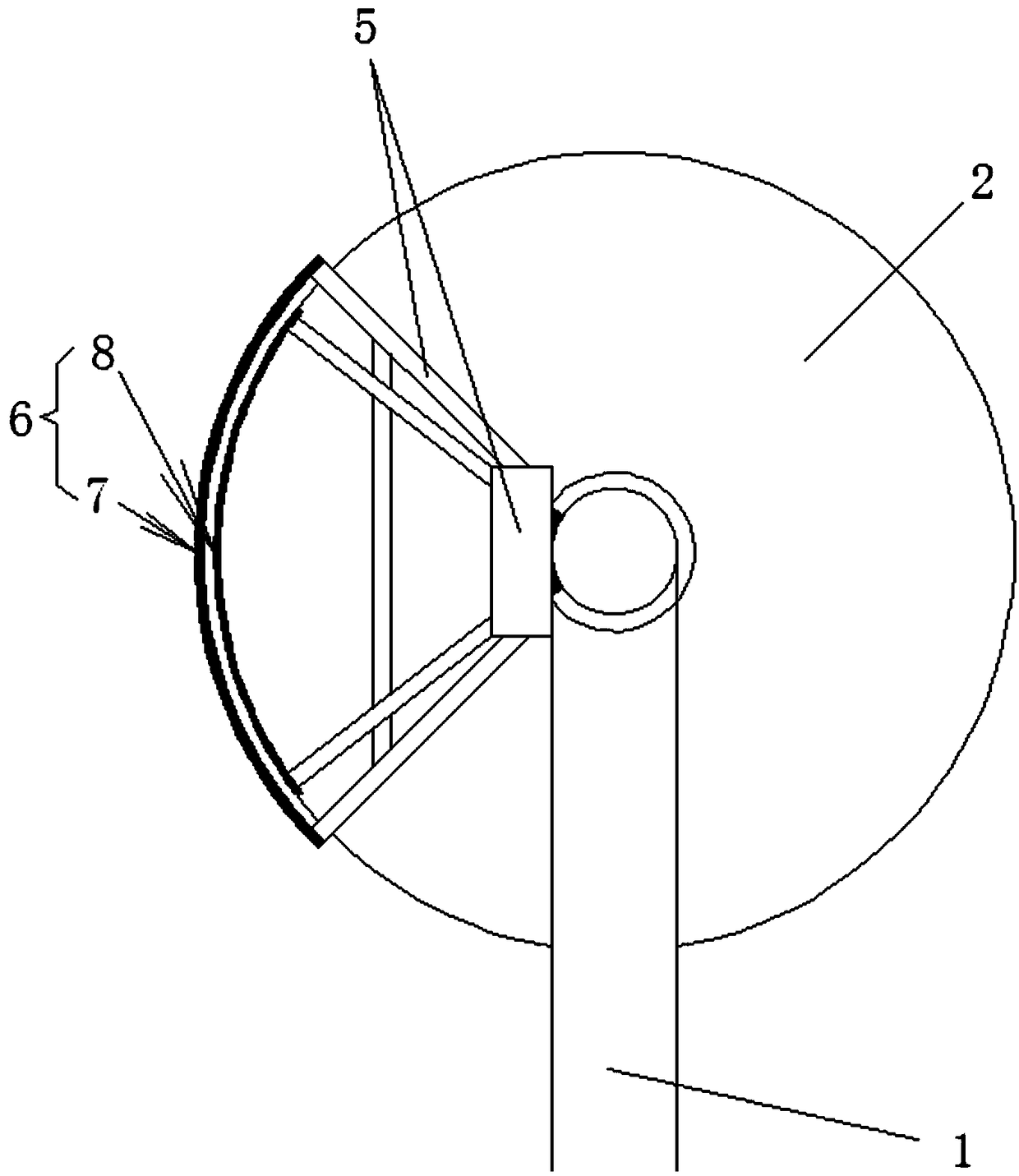

[0034] Such as Figures 1 to 3 Shown is an embodiment of a fast inspection tool for tank adjustment blocks of the present invention after installation, including a long handle 1 and a roller sample block 2 installed on the long handle 1, and the front end of the long handle 1 is provided with A section of bending section 3, and on said bending section 3, said 2 pieces of rotatable rollers are arranged.

[0035] Preferably, the long handle 1 is a long handle made of stainless steel multi-core tube, and the tail of the long handle 1 is connected with a nylon handle 4 .

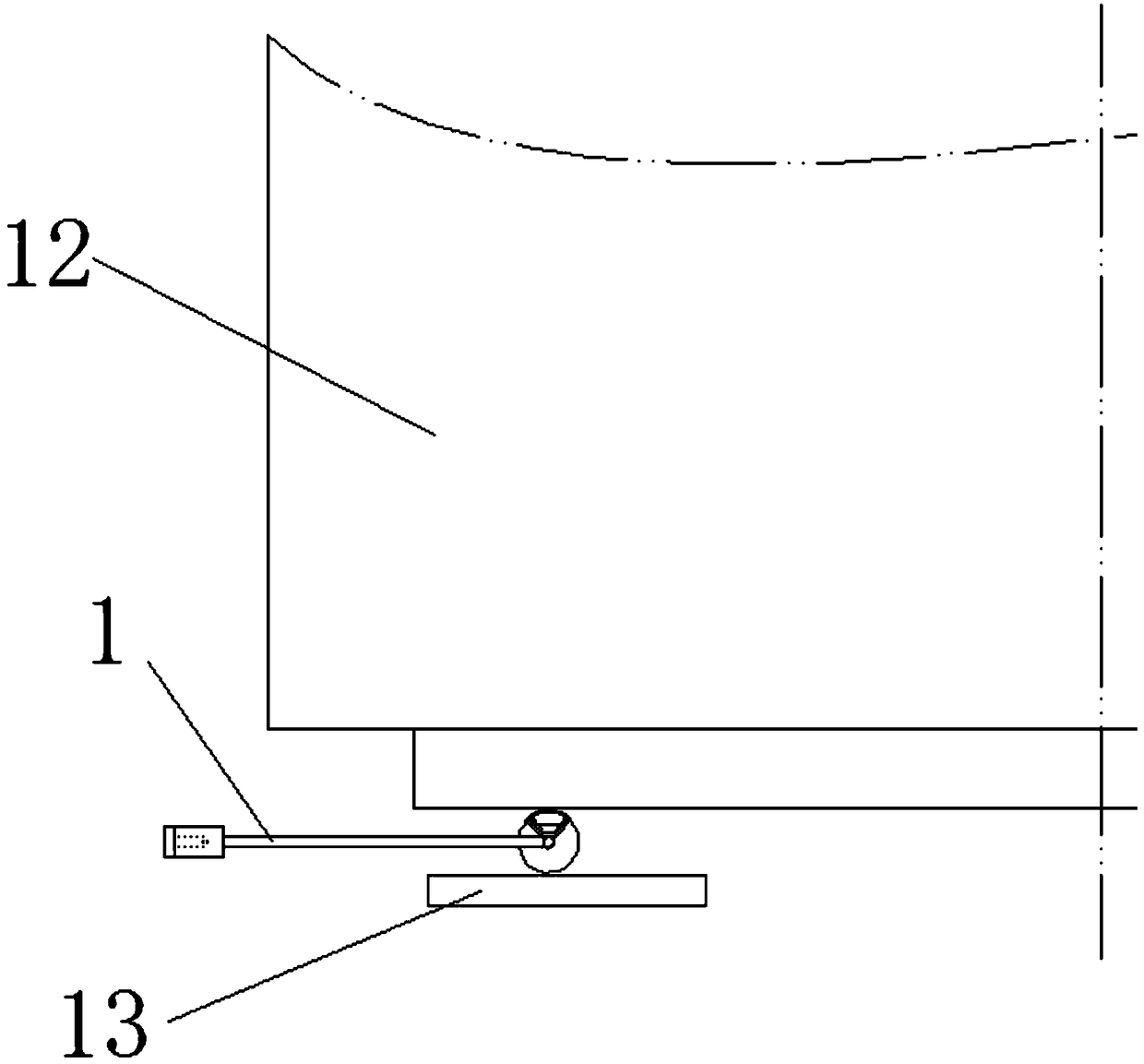

[0036] The roller samples 2 in the above-mentioned inspection tooling can be made into a series of specifications in advance, and can be selected according to the needs during the inspection, so as to determine the upper limit and the distance between the bottom of the cargo tank 12 and each adjustment pad 13 before the cargo tank is placed lower limit.

[0037]The above inspection tool includes a long handle ...

Embodiment 2

[0044] A method for quickly inspecting the installation of cargo tank adjustment pads by using the tooling of the above embodiment, comprising the following steps:

[0045] (1) Holding the long handle 1, place the roller sample block 2 at the front end of the long handle 1 against the upper plane of the adjustment block 13, and roll and push the roller sample block 13 into the adjustment block 13 and the bottom of the cargo tank 12 before falling into the tank Back and forth movement detection between planes;

[0046] (2) During the detection process, observe whether the roller sample block 2 is stuck, and observe whether the signal lamp 10 continues to shine during the detection process;

[0047] (3) If the roller sample block 2 is not stuck during the detection process, and at the same time the signal light 10 continues to light up during the detection process, it is judged that the installation of the cargo tank adjustment pad 13 is qualified.

[0048] Wherein, the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com