A stealth exhaust pipe with adjustable tapered cavity

A conical cavity, exhaust pipe technology, applied in jet propulsion devices, machines/engines, mechanical equipment, etc., can solve complex exhaust pipe and engine matching, stealth coating materials are easy to fall off, cannot cover high temperature parts, etc. It can improve the stealth performance of radar, avoid angular reflection, and improve the performance of infrared stealth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

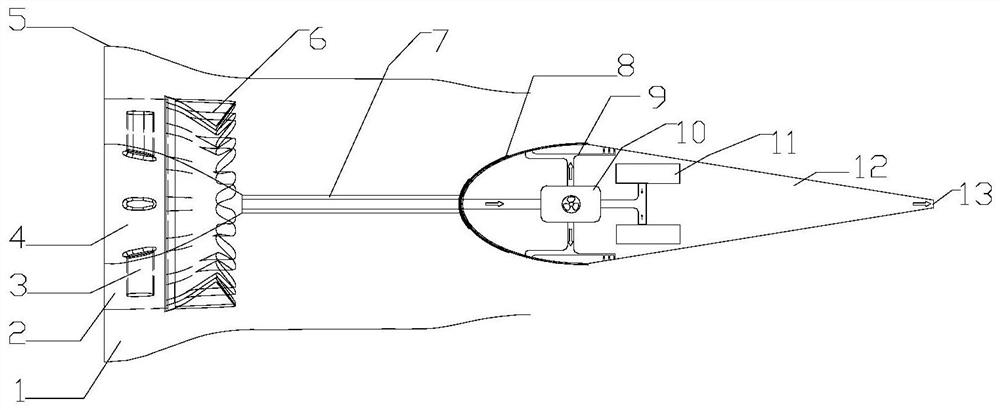

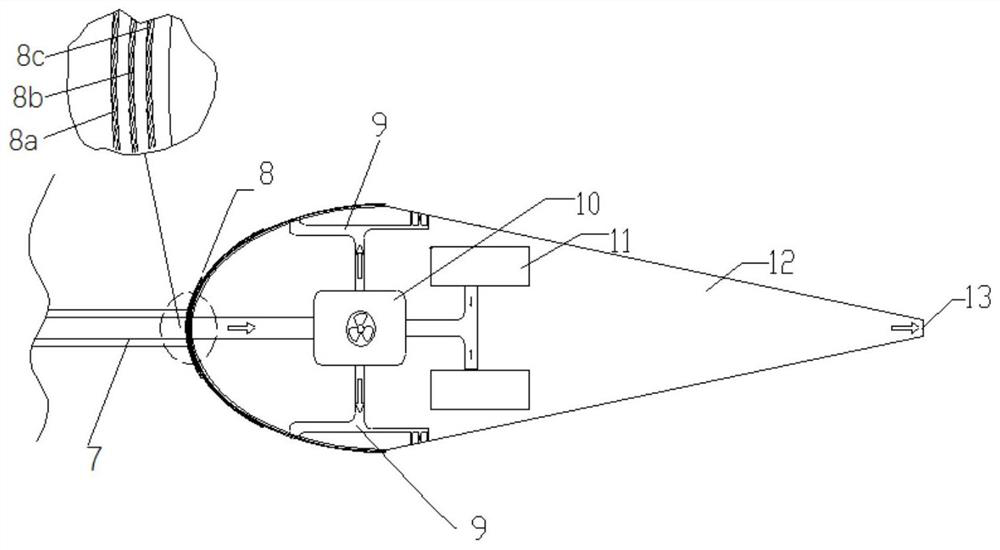

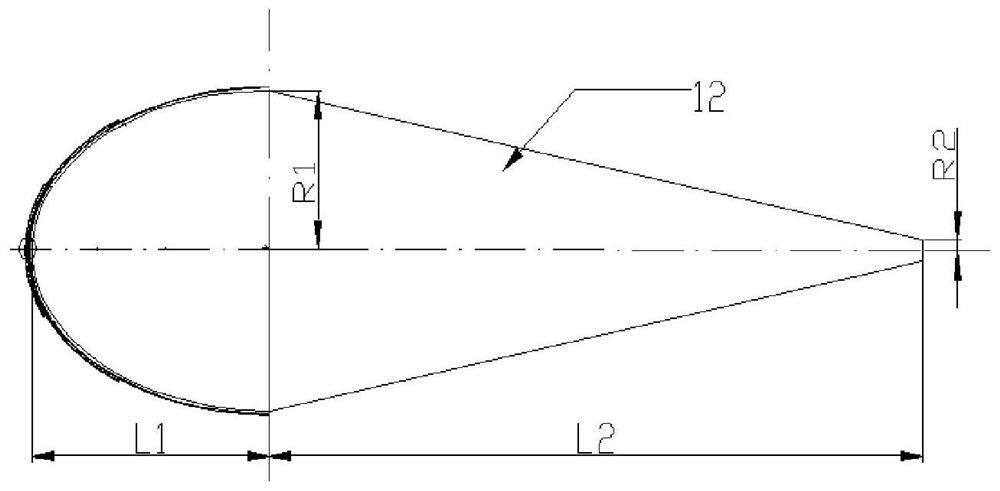

[0026] A stealth exhaust pipe with an adjustable tapered cavity, including an exhaust system, the exhaust system includes an outer duct 1, an inner duct 2, a support plate 3, a central cone 4, a nozzle wall 5 and a mixing 6, the outer duct 1 is set outside the inner duct 2, the central cone 4 is set inside the mixer 6, the support plate 3 is set outside the central cone 4, and also includes a telescopic sleeve 7, a tapered cavity Body 12 and aerosol injection device 10, the telescopic sleeve 7 is arranged on the top of the central cone 4, the telescopic sleeve 7 includes an inner sleeve and an outer sleeve, and the main function of the telescopic sleeve is to place the central cone The cooling air flow is introduced into the conical cavity 12, and the inner sleeve passes through the conical cavity 12 to communicate with the aerosol injection device 10 arranged inside the conical cavity 12, and the inside of the conical cavity 12 Several aerosol storage devices 11 are provided,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com