A kind of infrared low emissivity coating containing graphene

A low emissivity, graphene technology, applied in camouflage paints, conductive paints, coatings, etc., can solve problems such as poor continuity of metallic pigments, and achieve the effect of reducing emissivity, reducing infrared radiation intensity, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] According to the above method, 34g flake floating aluminum powder, 0.5g modified graphene, 50g hydroxyl acrylic resin, 1.2g titanium dioxide, 2.5ml butyl acetate, 0.5g thixotropic agent, 0.6g defoamer, 0.5g disperse solvent, 7ml xylene and 7ml cyclohexanone to make a coating.

Embodiment 2

[0044] According to the above method, 33g flake floating aluminum powder, 1g modified graphene, 50g hydroxyacrylic resin, 1.2g titanium dioxide, 2.5ml butyl acetate, 0.5g thixotropic agent, 0.6g defoamer, 0.5g dispersant , 7ml xylene and 7ml cyclohexanone to make a coating.

Embodiment 3

[0046] According to the above method, 32g flake floating aluminum powder, 1.5g modified graphene, 50g hydroxy acrylic resin, 1.2g titanium dioxide, 2.5ml butyl acetate, 0.5g thixotropic agent, 0.6g defoamer, 0.5g disperse solvent, 7ml xylene and 7ml cyclohexanone to make a coating.

[0047] Add an aliphatic isocyanate curing agent to the coating prepared in Examples 1-3, disperse and mix evenly at a high speed, spray it on a clean tinplate with a spray gun, and place it in an oven for 60 Dry at ~80°C for 6 hours to form a coating. After the blackbody temperature of the infrared emissivity tester is stabilized at 80 °C, install an 8-14 μm filter, and after instrument calibration, measure the infrared emissivity of the coating in the range of 8-14 μm.

[0048] The properties of coatings measured by national standards are shown in the table below:

[0049]

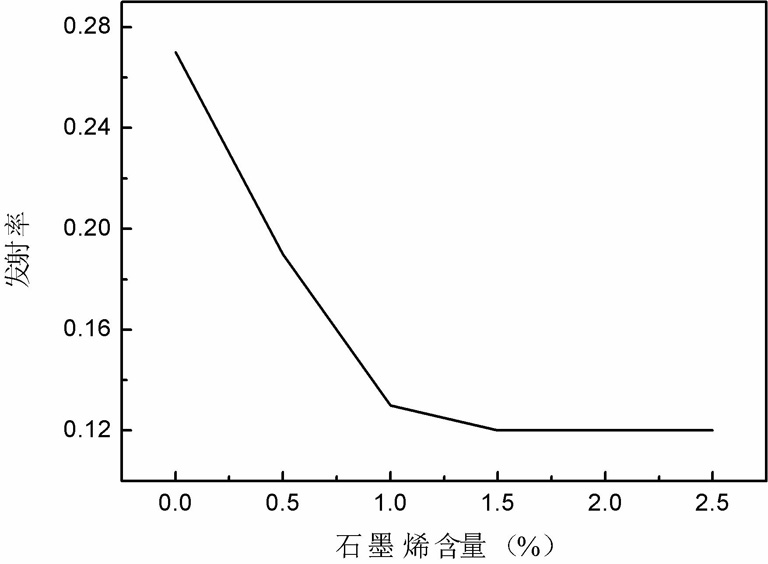

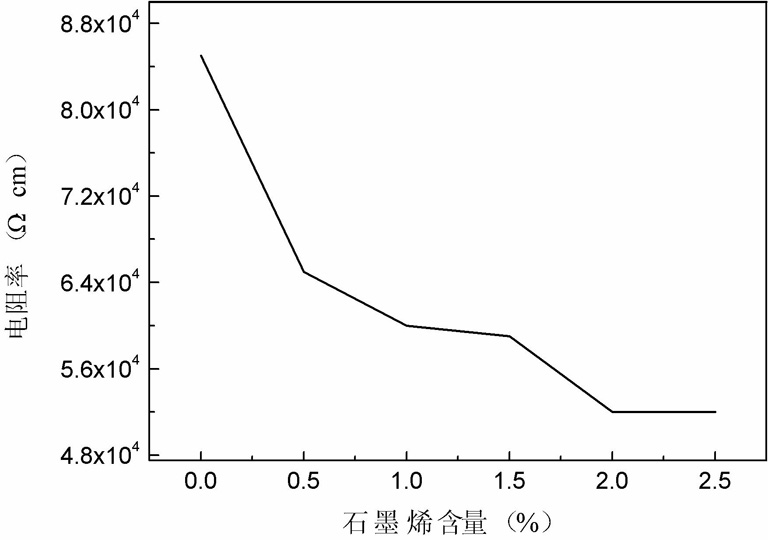

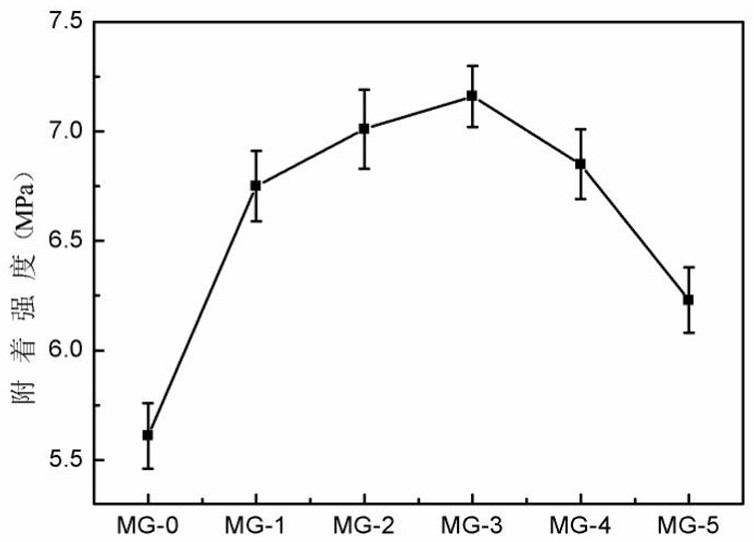

[0050] The addition of floating aluminum powder is selected as 35% of the coating weight, and the addition of modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com