Abrasion monitoring and cleaning device for cutter head of shield tunneling machine

A technology for cleaning devices and shield machines, which is applied in the field of shield machines, can solve problems such as the temperature rise of the cutter head 2, the brittleness of the cutter head 2, and the impact on the excavation project of the shield machine, so as to achieve a simple structure of the device and improve the use of Longevity and effect of improving tunneling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

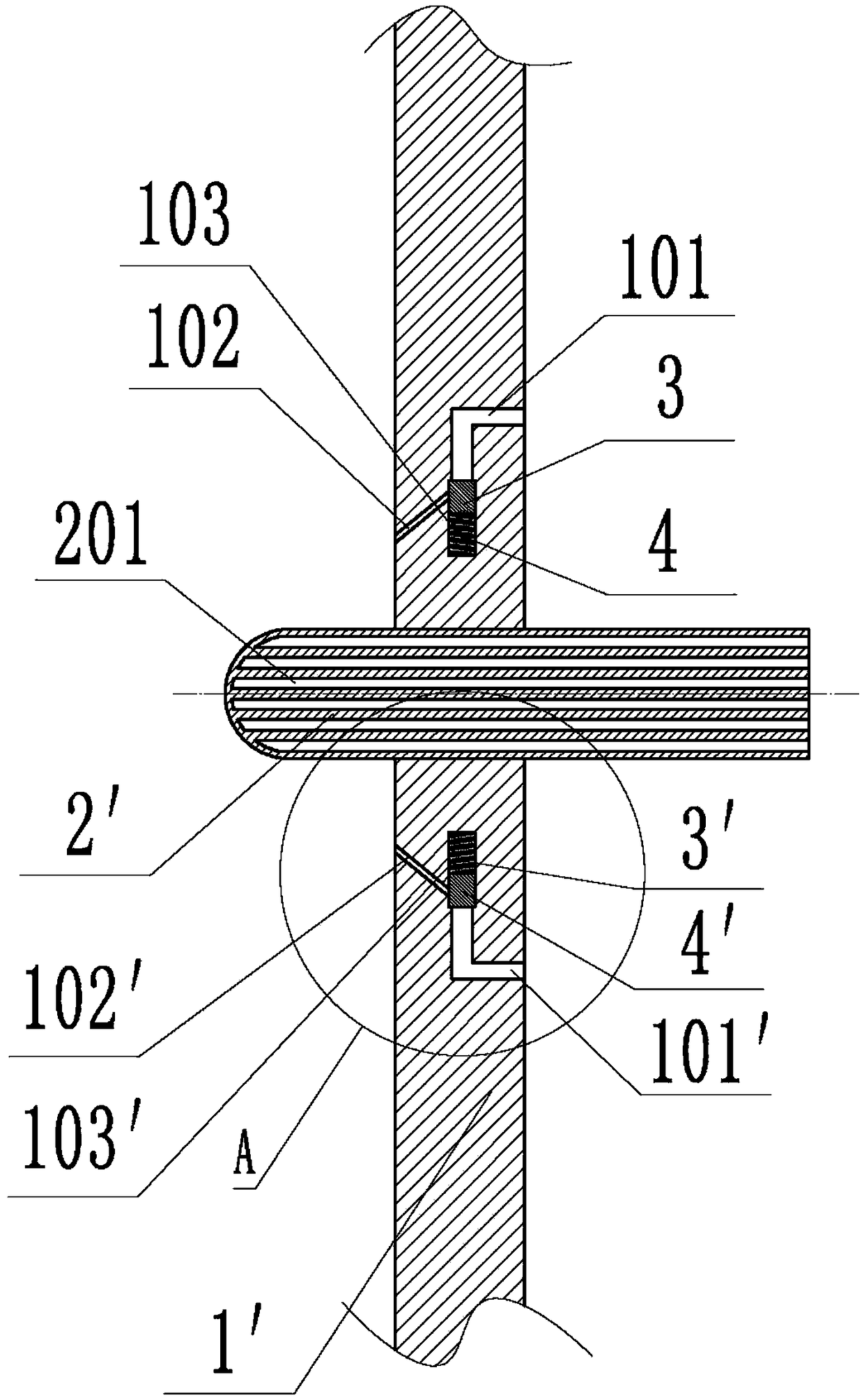

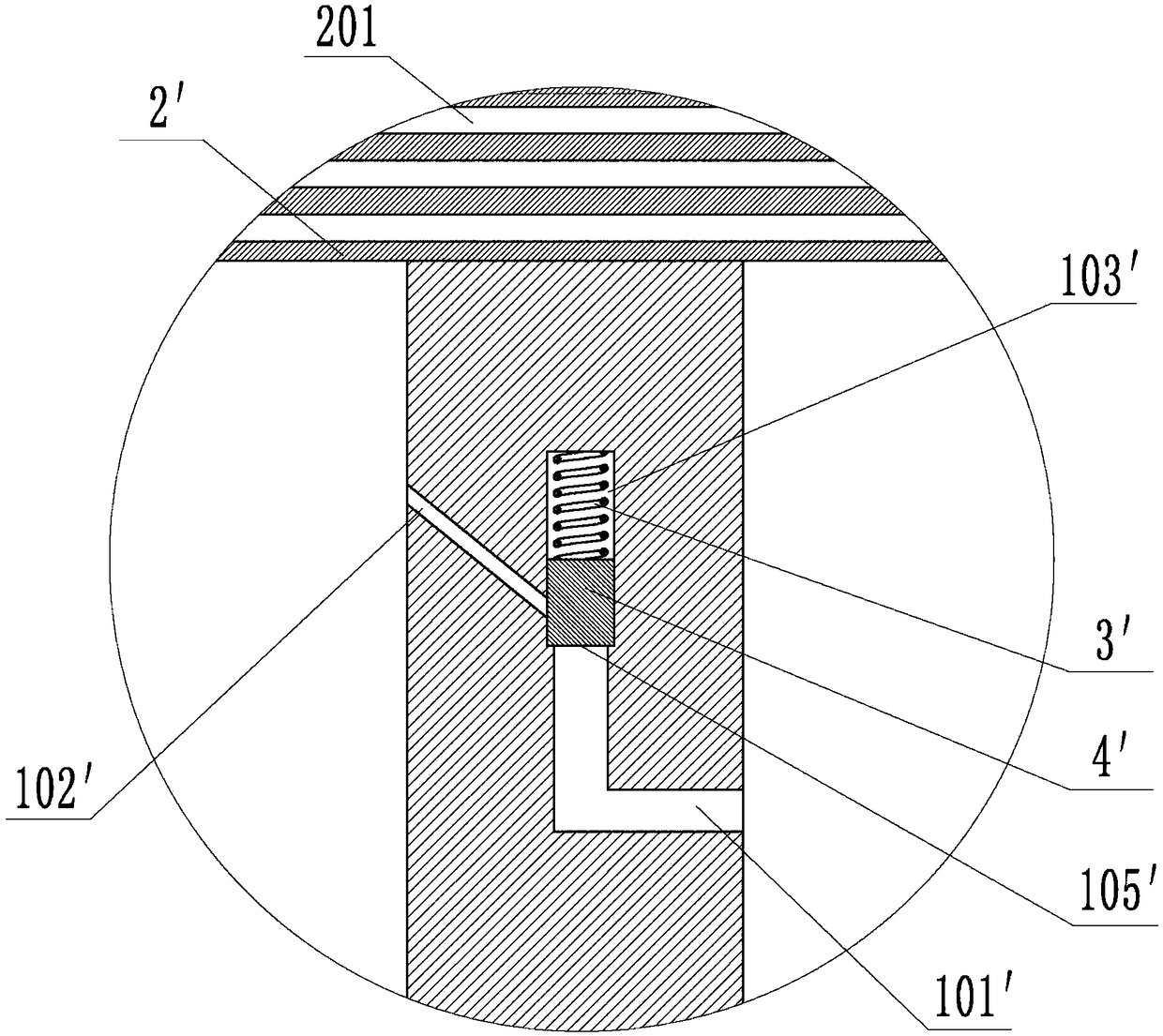

[0012] Such as figure 2 , 3 As shown, when the wear condition of the new cutter head 2' needs to be monitored, the cleaning of the new cutter head 2' needs to be completed at first. The lower piston 4, 4' compresses the upper and lower springs 3, 3' until the upper and lower high-pressure water inlets 101, 101' are connected with the upper and lower high-pressure water nozzles 102, 102', and the high-pressure water is sprayed from the upper and lower high-pressure The nozzles 102, 102' spray out to complete the cleaning of the new cutter head 2'; then feed high-pressure air into the blind hole air cavity 201, if there is an air leakage phenomenon, the new cutter head 2' will wear more seriously. And the degree of wear can be judged by monitoring the number of air leakage holes in the blind hole air cavity 201 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com