Water and polymer layered injection device suitable for offshore oil fields

A technology for offshore oilfields and injection ports, which is applied in the direction of wellbore/well valve devices, production fluids, wellbore/well components, etc., and can solve the problem of retention, unsatisfactory monitoring, multi-layer injection, and impact on polymer injection wells Problems such as water accumulation, injection and allocation efficiency can be achieved to reduce operating costs, realize downhole parameter monitoring, and improve the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

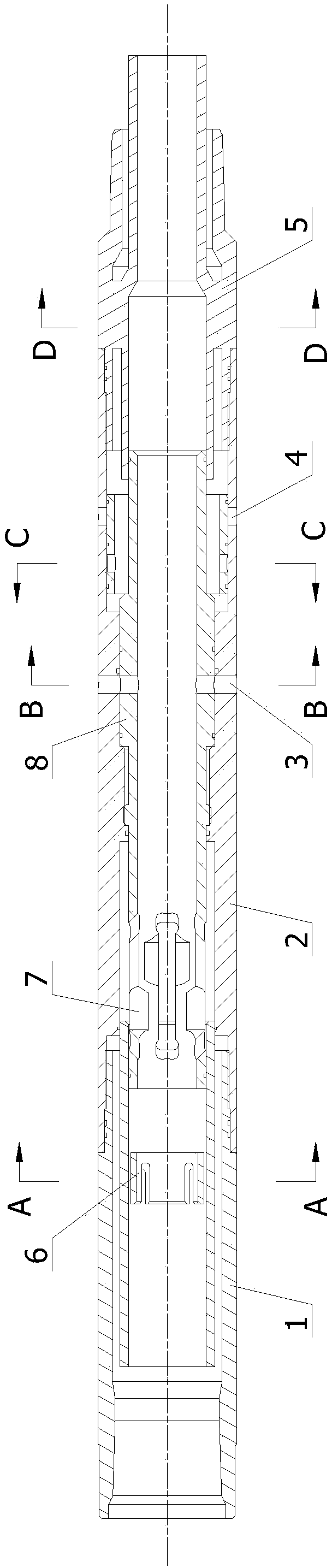

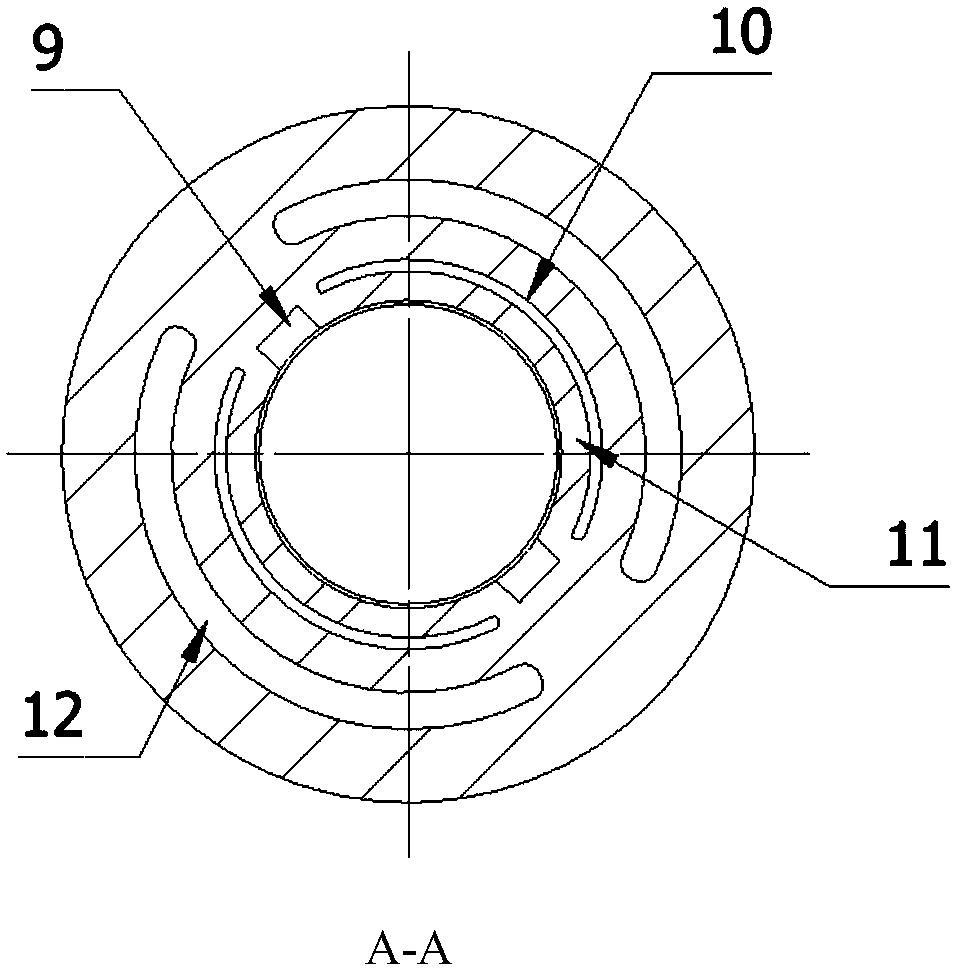

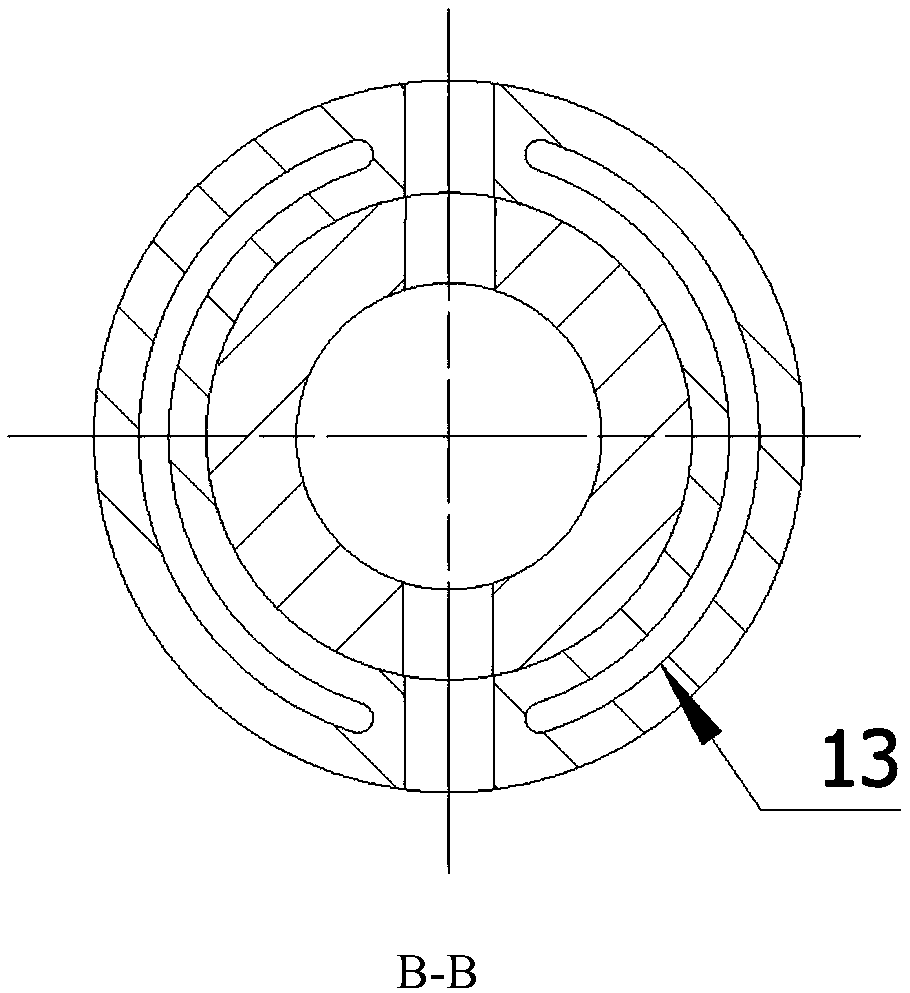

[0036] Such as figure 1As shown, one embodiment of the present invention discloses a water-polymer injection device suitable for offshore oil fields. The device mainly involves the polymer injection process in offshore oil fields. In the layered injection of polymer wells, each layer is connected in series to realize the layered injection and adjustment of water and polymer media in multi-layered polymer injection wells in offshore oilfields. The device is mainly composed of an upper joint 1, an outer cylinder 2, a lower joint 5 and a middle adjustment shaft 8, forming two major injection channels, a central injection channel and a bridge-type injection channel, which are respectively used as a water injection channel and a polymer injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com