Steel wire rope with high structural stability and preparation process thereof

A technology of structural stability and preparation process, applied in textiles and papermaking, clothing belts, clothing and other directions, can solve the problems of increasing process steps and production costs, and achieve the improvement of rubber leakage rate, safety and service life. The effect of increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

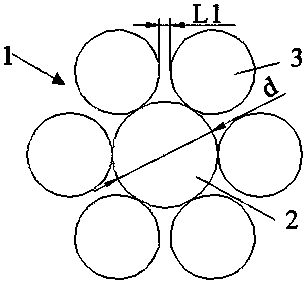

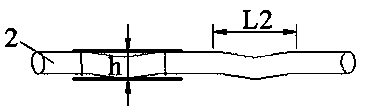

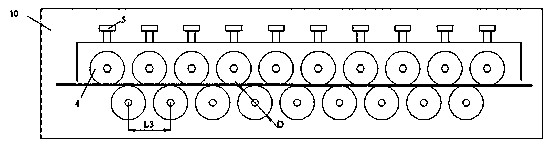

[0029] Figure 4 Shown is a schematic diagram of a transverse cross-sectional structure of a specific application case of the steel wire rope with high structural stability of the present invention. Composed of wound steel wires 7, wherein the diameter of the central steel wire 6 is 0.30 mm, and the diameter of the outer wound steel wire 7 is 0.185 mm; all steel wires are galvanized steel wires, and the deformation height of the central steel wire is measured by a precision profile projector to be 0.345 mm.

[0030] Choose the steel wire rope 18185NT of the same specification under the prior art to compare the adhesion performance with the steel wire rope of the present invention. The rubber material selected for the vulcanization experiment is provided by Shandong Yihe Conveyor Belt Co., Ltd. The test data are shown in Table 1 below.

[0031]

[0032] As can be seen from the test data in Table 1, under the same specification, the steel wire rope in the present invention ha...

Embodiment 2

[0034] Figure 5 Shown is a schematic diagram of the transverse section structure of another specific application case of the steel wire rope with high structural stability of the present invention, the structure of which is a 7×7 alternate twist structure; the steel wire rope is composed of seven strands of steel wire rope, and each strand contains seven Steel wires, wherein the central steel wire 8 in the core strand 20 is deformed, and the deformation height h can be measured by a precision profile projector; the six outer winding strands 30 are consistent with the prior art, and all steel wires are galvanized steel wires.

[0035] In this case, the diameter of the central steel wire 8 is 0.25mm, the diameter of the outer winding steel wire 9 is 0.235mm, the diameter of the outer winding central steel wire 11 is 0.23mm, and the diameter of the outer winding steel wire 12 is 0.215mm. The center wire 8 is deformed by using a straightening device for deformation. In this case,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com