Processing method for organic cotton rope serving as electronic cigarette liquid guide strip

A processing method and electronic cigarette technology, applied in the field of electronic cigarettes, can solve the problems of difficult processing, reduced manufacturing efficiency, uneven sliver density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

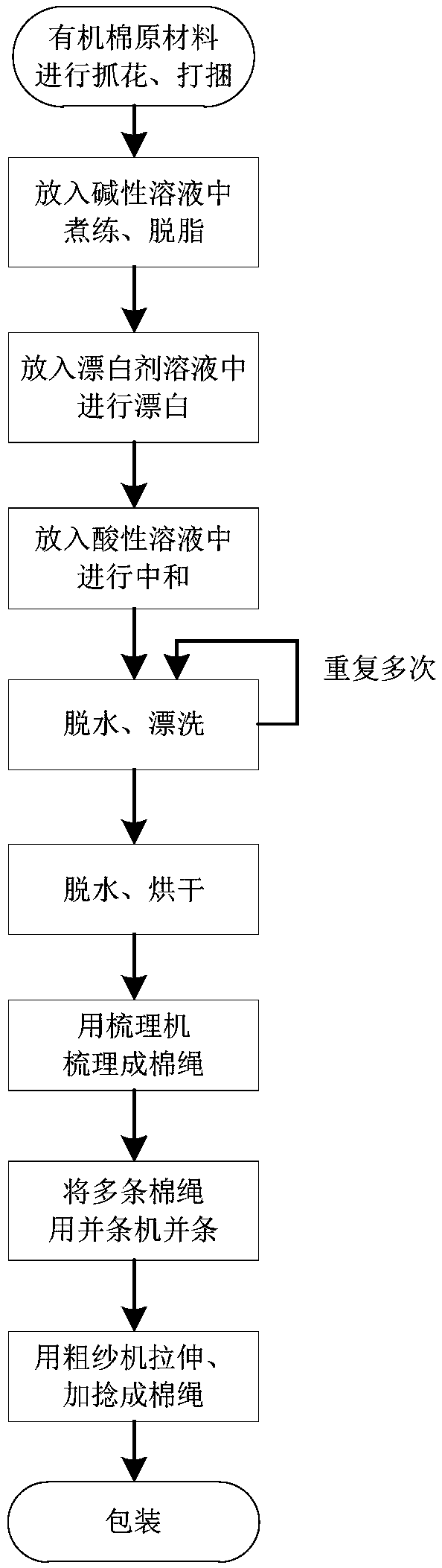

[0028] Such as figure 1 As shown, the technical solution of the present invention is realized in this way: the processing method of the organic cotton rope used as an electronic cigarette liquid guide strip includes the following steps:

[0029] 1) Put the organic cotton raw materials into the flower grabbing machine for grabbing and bundling;

[0030] 2) putting the above-mentioned organic cotton into a container filled with a certain concentration of NaOH solution for scouring and degreasing;

[0031] 3) After dehydrating the above-mentioned organic cotton, put it into a container filled with a certain concentration of hydrogen peroxide solution for bleaching;

[0032] 4) After the above-mentioned organic cotton is dehydrated, put it into a container filled with a certain concentration of citric acid solution to neutralize the pH;

[0033] 5) putting the above-mentioned organic cotton into purified water for rinsing after dehydration;

[0034] 6) Repeat step 5) 3 times; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com