Composite modified montmorillonite rubber functional filler with flame retardant and reinforcing performance

A technology of composite modification and functional filler, applied in the field of composite modified montmorillonite rubber functional filler and its preparation, can solve the problems of low added value of montmorillonite utilization, single performance, poor compatibility, etc., and achieve high resource utilization. The effect of value-added recycling, increasing interlayer spacing and specific surface area, and reducing industry costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

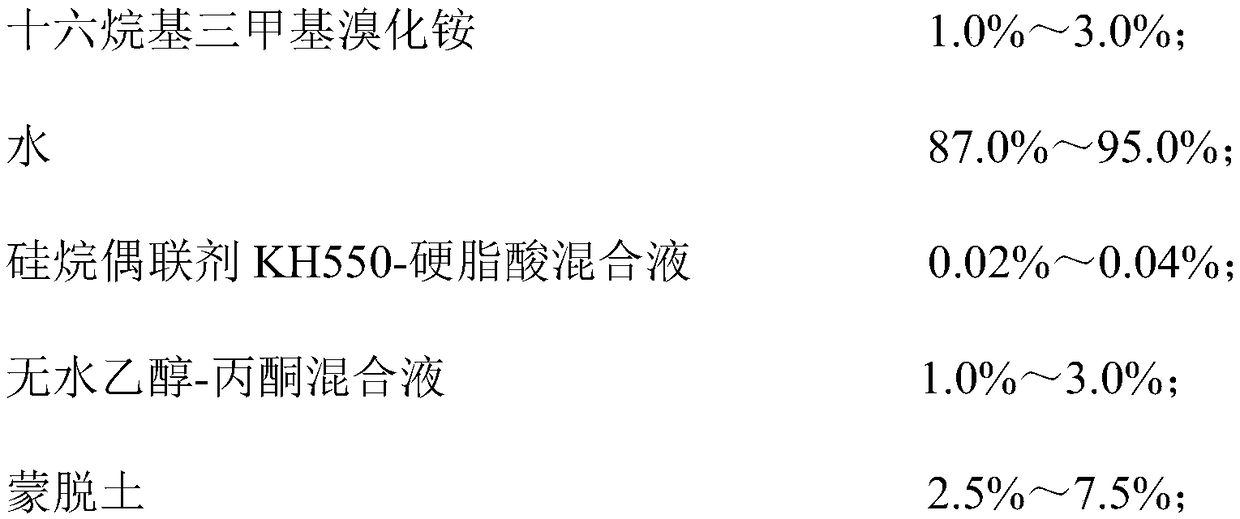

[0020] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0021]

[0022] The mass ratio of silane coupling agent KH550 and stearic acid in described silane coupling agent KH550-stearic acid mixed solution is 1:2, and silane coupling agent KH550 is industrial pure, and stearic acid is analytical pure; The mass ratio of absolute ethanol to acetone in the water ethanol-acetone mixture is 3:1, the absolute ethanol is analytically pure, and the acetone is industrial pure; the montmorillonite is calcium-based montmorillonite.

[0023] First, montmorillonite and water were mixed uniformly at a stirring speed of 2500r / min for 7h and allowed to stand for 6h to obtain a montmorillonite solution; hexadecyltrimethylammonium bromide and 3mL concentrated hydrochloric acid were stirred to obtain a protonated solution, And under the conditions that the stirring speed is 2500r / min and the stirring temperature...

Embodiment 2

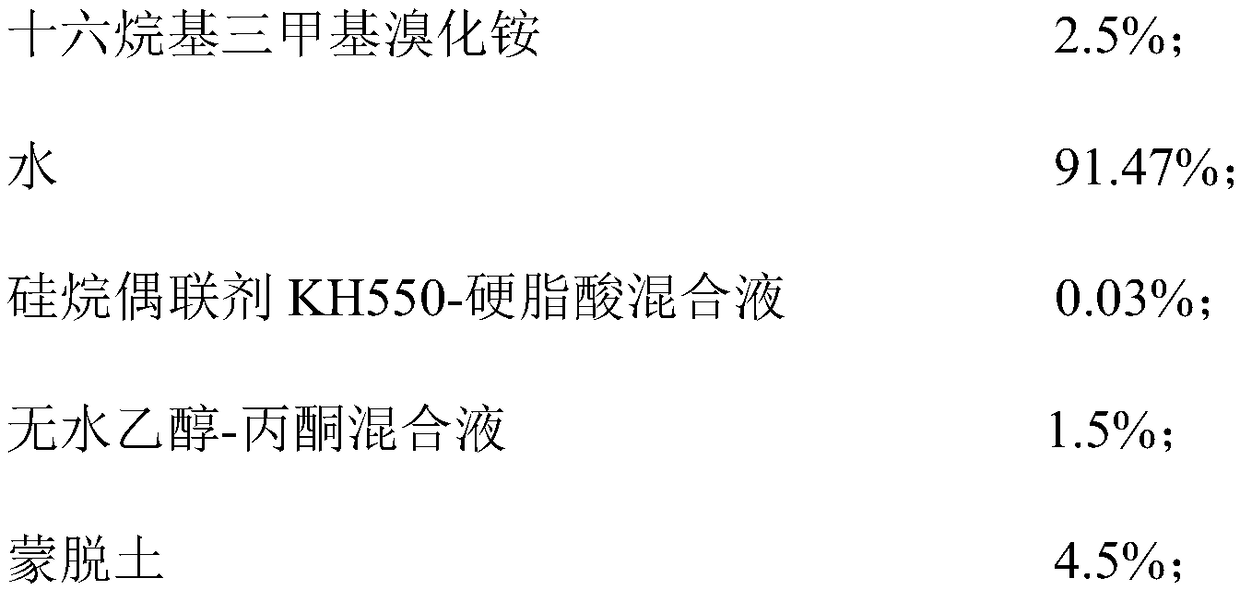

[0025] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0026]

[0027] The mass ratio of silane coupling agent KH550 and stearic acid in described silane coupling agent KH550-stearic acid mixed solution is 1:1, and silane coupling agent KH550 is industrial pure, and stearic acid is analytical pure; The mass ratio of absolute ethanol to acetone in the water ethanol-acetone mixture is 1:3, the absolute ethanol is analytically pure, and the acetone is industrial pure; the montmorillonite is magnesium-based montmorillonite.

[0028] First, the montmorillonite and water were uniformly mixed at a stirring speed of 4000r / min for 4h and allowed to stand for 6h to obtain a montmorillonite solution; cetyltrimethylammonium bromide and 5mL of concentrated hydrochloric acid were stirred to obtain a protonated solution, And under the condition that the stirring speed is 4000r / min and the stirring tempera...

Embodiment 3

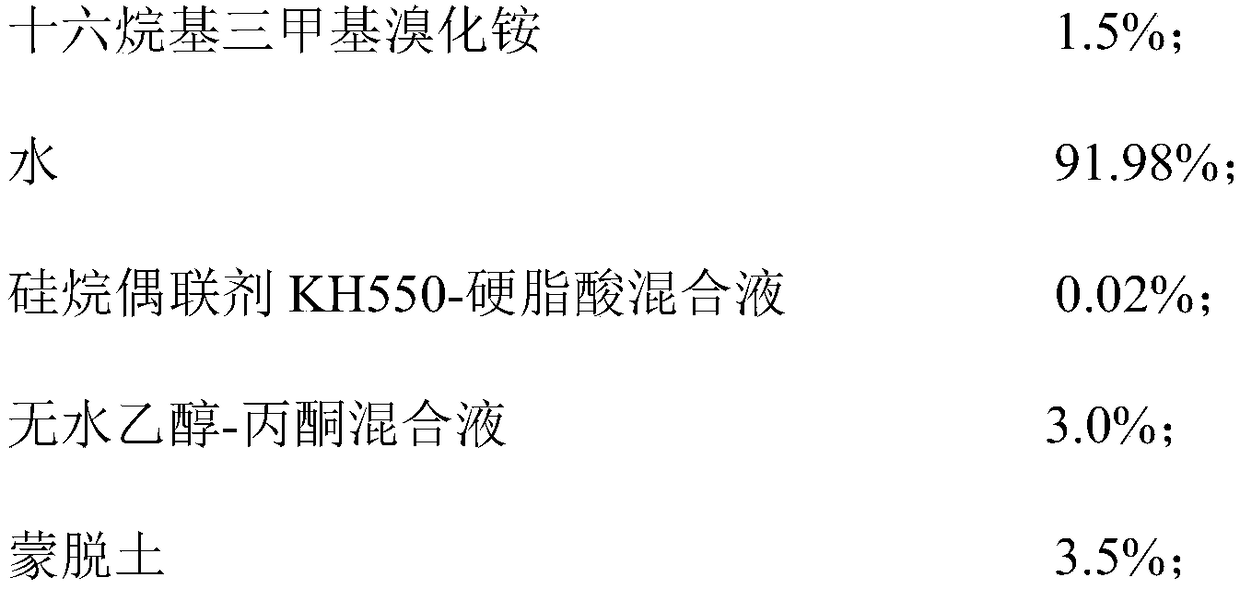

[0030] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0031]

[0032]

[0033] The mass ratio of silane coupling agent KH550 and stearic acid in described silane coupling agent KH550-stearic acid mixed solution is 3:1, and silane coupling agent KH550 is industrial pure, and stearic acid is analytical pure; The mass ratio of absolute ethanol to acetone in the water ethanol-acetone mixture is 2:1, the absolute ethanol is analytically pure, and the acetone is industrial pure; the montmorillonite is sodium-based montmorillonite.

[0034] First, mix montmorillonite and water uniformly at a stirring speed of 3500r / min for 6h and let stand for 6h to obtain a montmorillonite solution; stir cetyltrimethylammonium bromide and 2mL concentrated hydrochloric acid to obtain a protonated solution, And under the conditions that the stirring speed is 3500r / min and the stirring temperature is 80°C, the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com