A kind of method and system thereof for recovering production solvent from nmp waste liquid

A waste liquid recovery and solvent technology, which is applied in the direction of organic chemistry, can solve the problems that the purity of NMP products in the second tower cannot be guaranteed, the waste water, tail gas and still residue cannot be effectively used, and the stability of the process is reduced, so as to save steam energy consumption, significant economic benefits, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

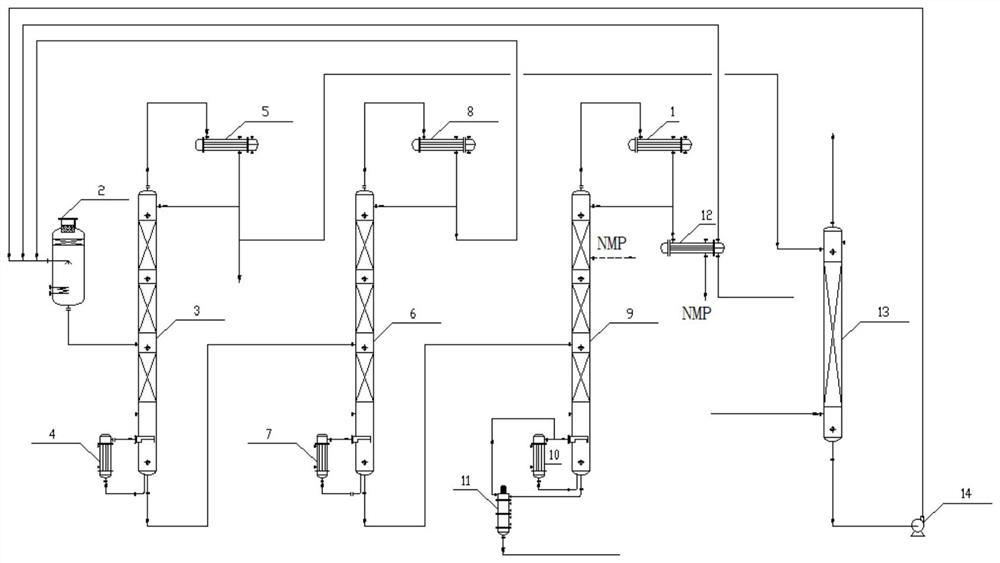

[0036] Embodiment 1: as figure 1 As shown, a system for recovering NMP waste liquid includes a raw material preheater 1, a deoxygenation tank 2, a dehydration tower 3, and a rectification tower 6. The specific recycling method includes the following steps:

[0037] Step 1. Raw material preheating: pump the waste liquid from the NMP waste liquid storage tank to the pre-raw material heater 1 for preheating;

[0038] Step 2. Deoxidation treatment: put the NMP waste liquid preheated in step 1 into the deoxidation tank 2 for deoxidation and non-condensable gas treatment. The operating temperature of the deoxidation tank 2 is 45°C and the operating pressure is -0.1MPa;

[0039] Step 3. Dehydration treatment: NMP waste liquid after deoxidation treatment is pumped to dehydration tower 3 for dehydration treatment. The temperature at the top of the dehydration tower is 50°C, the temperature of the bottom of the dehydration tower is 120°C, and the pressure at the top of the dehydration ...

Embodiment 2

[0044] Such as figure 1 As shown, a system for recovering NMP waste liquid includes a raw material preheater 1, a deoxygenation tank 2, a dehydration tower 3, and a rectification tower 6. The specific recycling method includes the following steps:

[0045] Step 1. Raw material preheating: pump the waste liquid from the NMP waste liquid storage tank to the raw material preheater 1 for preheating;

[0046] Step 2. Deoxidation treatment: put the NMP waste liquid preheated in step 1 into the deoxidation tank 2 for deoxidation and non-condensable gas treatment. The operating temperature of the deoxidation tank 2 is 45°C and the operating pressure is -0.08MPa;

[0047] Step 3. Dehydration treatment: NMP waste liquid after deoxidation treatment is pumped to dehydration tower 3 for dehydration treatment. The temperature at the top of the dehydration tower is 60°C, the temperature of the bottom of the dehydration tower 3 is 130°C, and the pressure at the top of the dehydration tower 3...

Embodiment 3

[0052] Such as figure 1 As shown, a system for recovering NMP waste liquid includes a raw material preheater 1, a deoxygenation tank 2, a dehydration tower 3, and a rectification tower 6. The specific recycling method includes the following steps:

[0053] Step 1. Raw material preheating: pump the waste liquid from the NMP waste liquid storage tank to the raw material preheater 1 for preheating;

[0054] Step 2. Deoxidation treatment: put the NMP waste liquid preheated in step 1 into the deoxidation tank 2 for deoxidation and non-condensable gas treatment. The operating temperature of the deoxidation tank 2 is 65°C and the operating pressure is -0.09MPa;

[0055] Step 3. Dehydration treatment: NMP waste liquid after deoxidation treatment is pumped to dehydration tower 3 for dehydration treatment. The temperature at the top of dehydration tower 3 is 55°C, the temperature at the bottom of the dehydration tower is 125°C, and the pressure at the top of the dehydration tower is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com