Kitchen waste composting barrel

A garbage composting and kitchen waste technology, which is applied in the field of kitchen waste composting buckets and composting buckets, can solve the problems of easy and difficult diffusion of odor, incomplete degradation of organic matter, etc., and achieve the effect of improving composting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

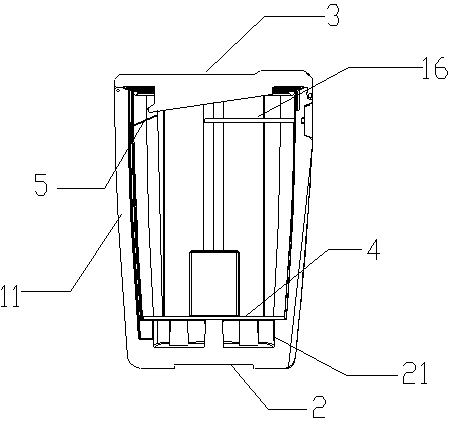

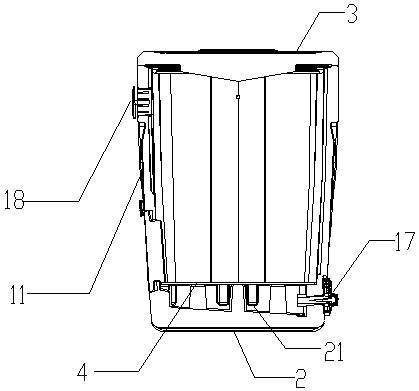

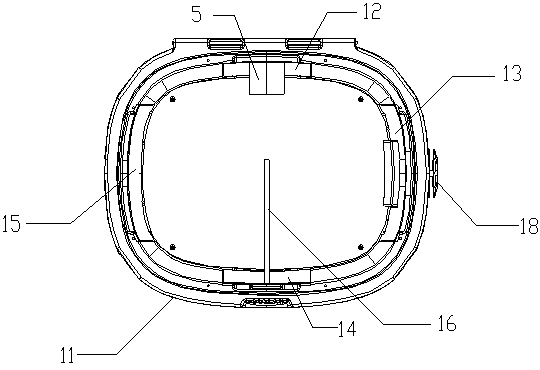

[0026] A kitchen waste compost bin, such as Figure 1-Figure 3 Shown, comprise staving and the bung 3 that is connected with staving, staving is provided with water filter plate 4, and the circumferential outside of water filter plate 4 contacts with the bucket wall 11 of staving, and water filter plate 4 will The barrel body is divided into a composting area positioned above the filter plate 4 and a filtered water collection area located below the filter plate 4; Inverted cone shape, because the inverted cone-shaped opening has the characteristics of a large top and a small bottom, it can better filter out the liquid in the kitchen waste, and prevent the solid waste in the kitchen waste from accumulating at the filter hole to filter the filter hole Blocking, convenient and practical, the staff in this technical field can also set up filter screen on the top of water filter plate 4 as required.

[0027] The inner side of barrel wall 11 is provided with a plurality of grooves,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com