Short wheelbase variable width frame assembly structure

An assembly structure and variable width technology, which is applied in the direction of the connection between the superstructure, the substructure, and the subassembly of the superstructure, can solve the problems of hidden safety hazards, self-heavy weight, weak torsion resistance of the frame, etc. Bending resistance and torsion resistance, weight and cost reduction, engine vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

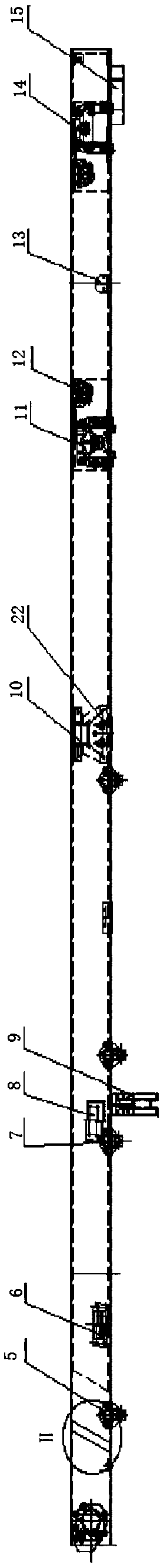

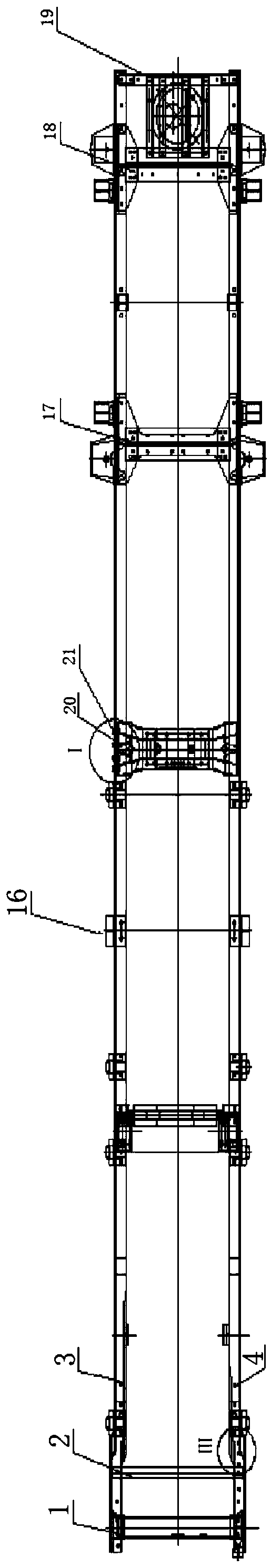

[0054] A frame assembly structure with a short wheelbase and variable width, comprising a first longitudinal beam 3, a second longitudinal beam 4, a tubular beam assembly 1, an arc beam assembly 9, a rear-front back-to-back beam assembly 17, a rear Back-to-back beam assembly 18, tail beam assembly 19;

[0055] The axis of the first longitudinal beam 3 is arranged parallel to the axis of the second longitudinal beam 4 , and the first end of the first longitudinal beam 3 and the first end of the second longitudinal beam 4 pass through The tubular beam assembly 1 is fixedly connected, with the first end of the first longitudinal beam 3 and the first end of the second longitudinal beam 4 as the front end of the frame assembly;

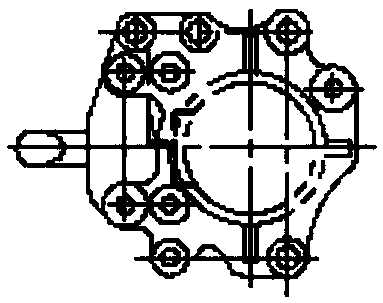

[0056] The tubular beam assembly 1 includes a tubular beam body and two connecting sleeves fixedly connected at both ends thereof, the two ends of the tubular beam body are respectively inserted into one ends of the two connecting sleeves, and the other en...

Embodiment 2

[0062] Compared with the solution of Embodiment 1, the short-wheelbase variable-width vehicle frame assembly structure also includes a spare tire support assembly 15, and the two ends of the spare tire support assembly 15 are respectively connected to the rear backrest beam assembly. 18 and the tail beam assembly 19 are fixedly connected.

[0063] It should be noted that the spare tire support assembly 15 mainly ensures the rationality of the installation position of the spare tire and the reliability and firmness of the installation; the tail beam assembly 19 ensures the installation of the spare tire support.

Embodiment 3

[0065] Compared with the solutions of Embodiments 1 and 2, the frame assembly structure with short wheelbase and variable width also includes two front leaf spring fixing supports 5 and two front lifting lug leaf spring supports 7, and the two front plates The spring fixing support 5 and the two front lug leaf spring supports 7 are symmetrically fixed on the first longitudinal beam 3 and the second longitudinal beam 4 respectively, and the front leaf spring fixing support 5 is located on the front lifting lug plate In front of the spring support 7 , the front leaf spring fixed support 5 and the front lug leaf spring support 7 are located between the tubular beam assembly 1 and the arc beam assembly 9 .

[0066] It should be noted that the front leaf spring fixing support 5 and the front lug leaf spring support 7 are mainly to ensure the reliability and safety of the connection between the vehicle frame assembly and the front suspension system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com