Automatic film tearing machine for accessory assembly

A film machine and auxiliary material technology, applied in lamination auxiliary operations, chemical instruments and methods, lamination, etc., can solve the problems of low tearing efficiency, affecting assembly accuracy and quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

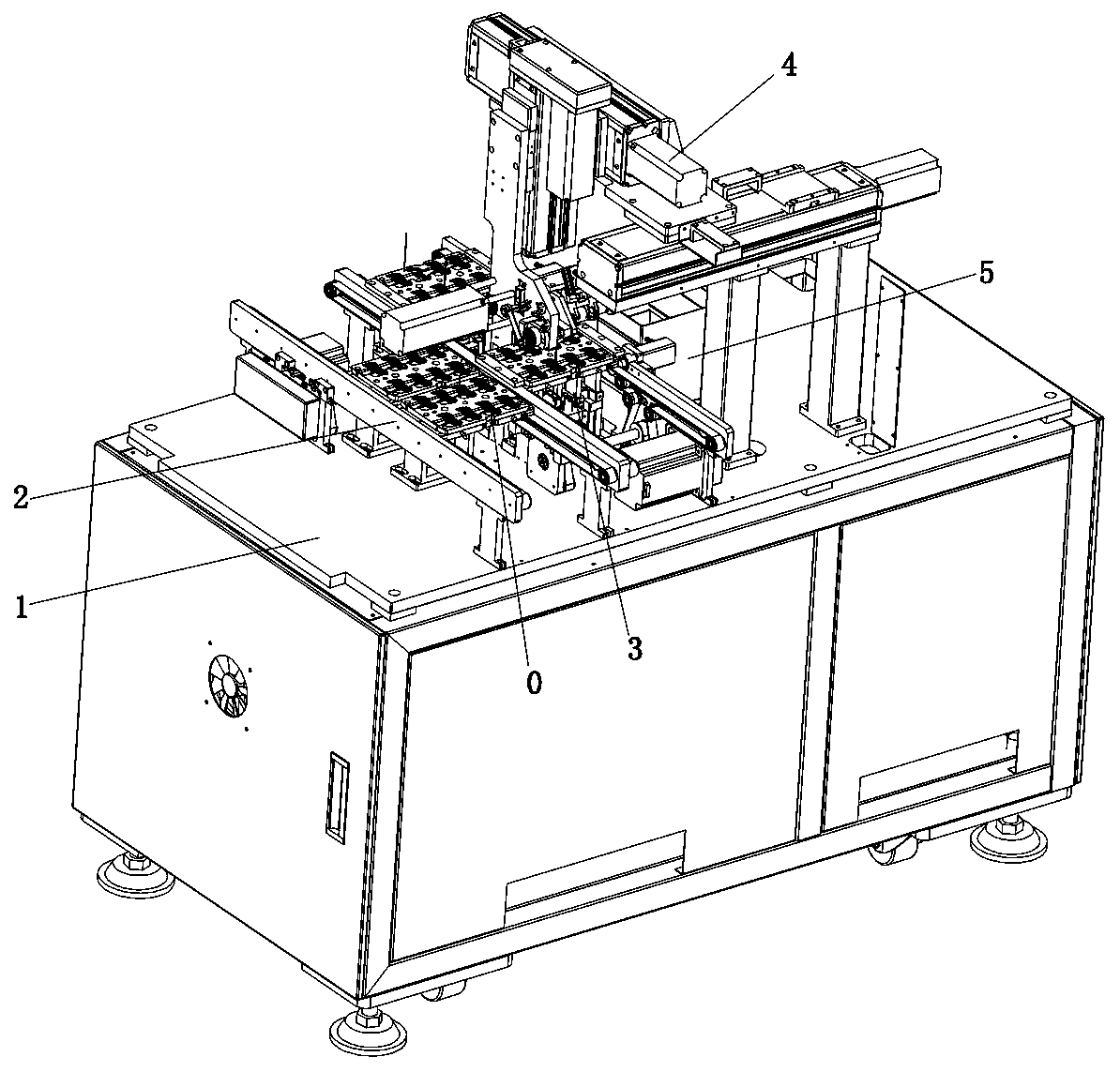

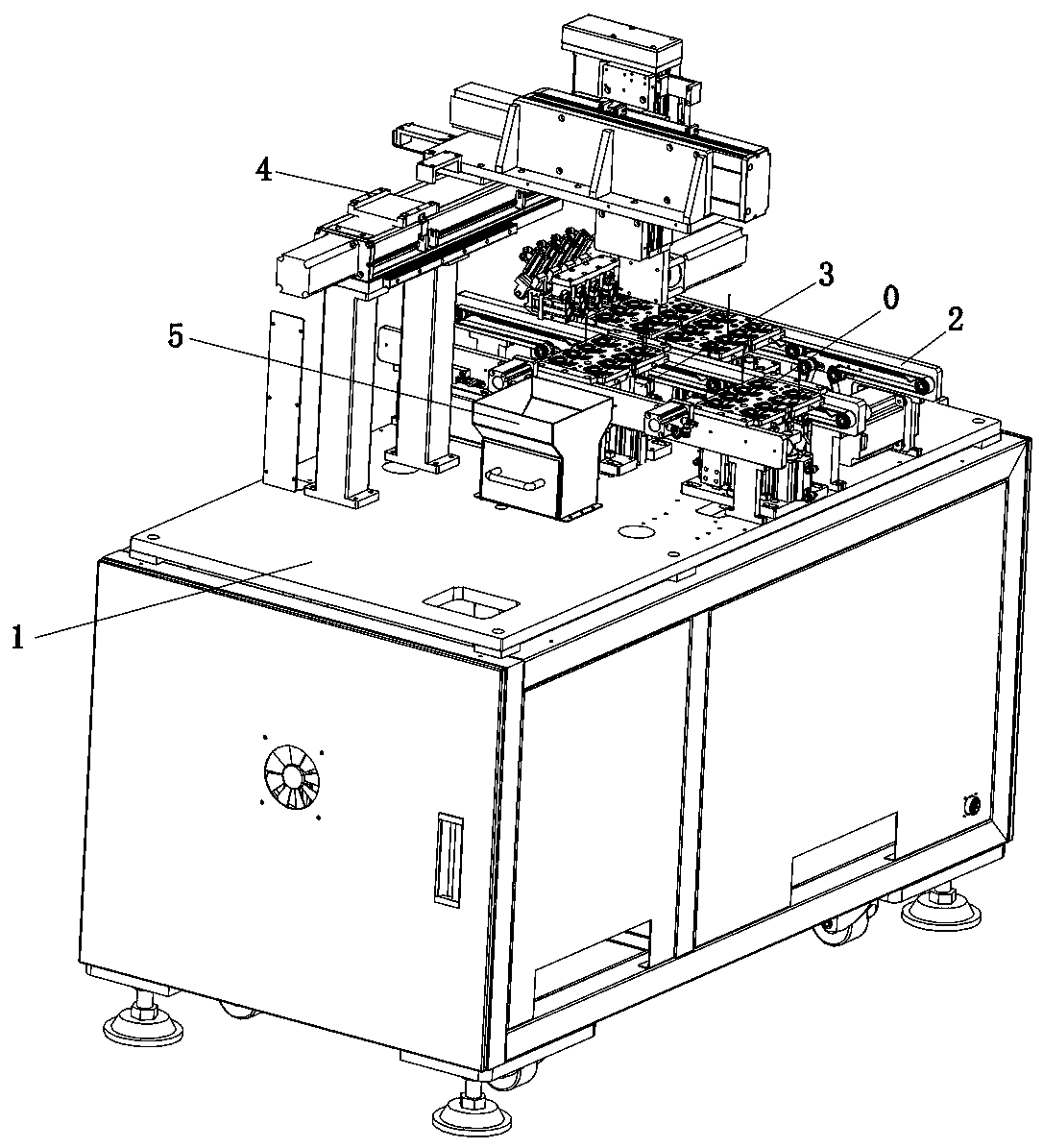

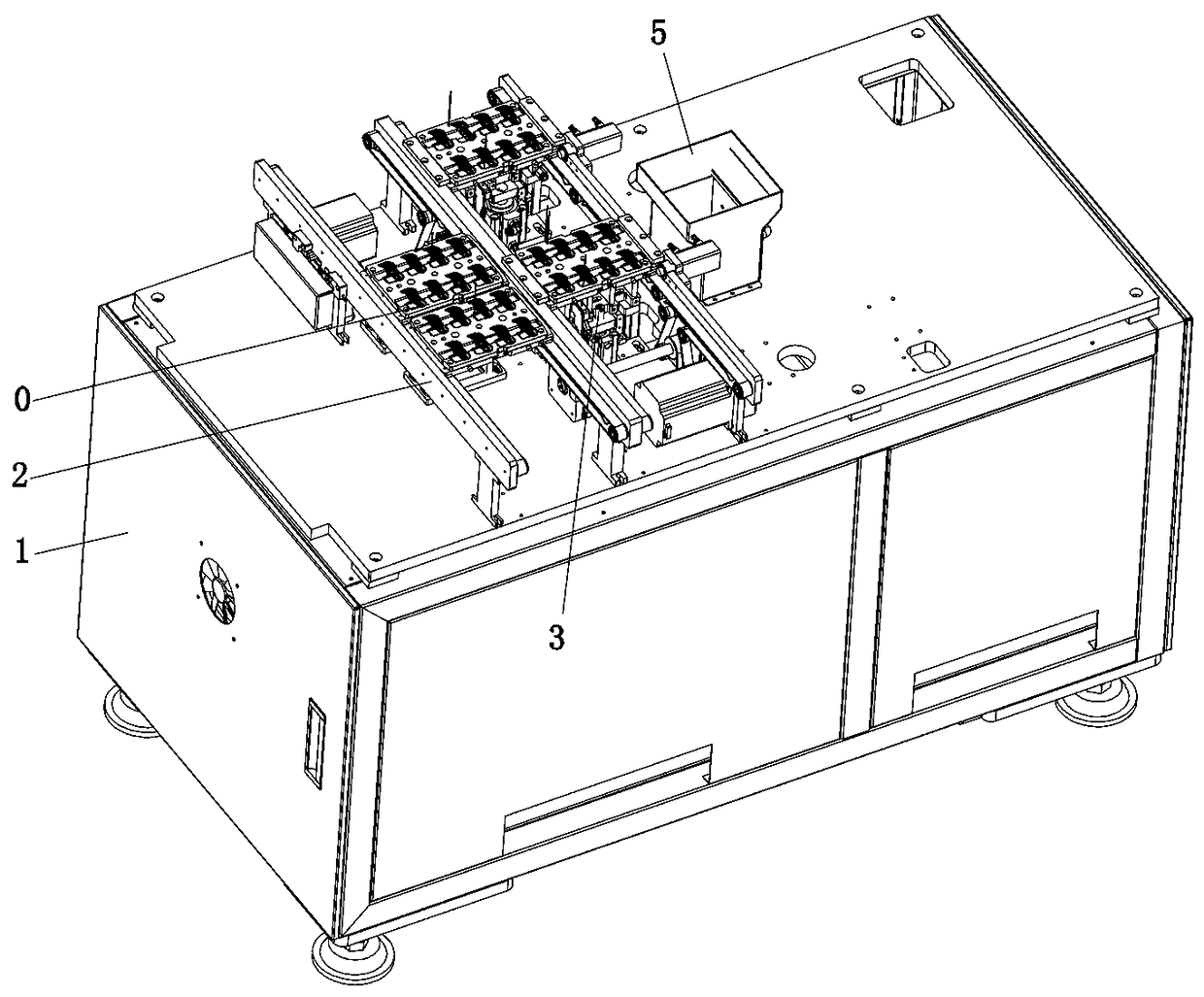

[0032] Such as Figure 1 to Figure 12 As shown, the technical solution adopted by the present invention is as follows: an automatic film tearing machine for auxiliary material assembly, including a transmission mechanism 2, a positioning and supporting mechanism 3, a film tearing mechanism 4 and a material box 5, wherein the above transmission mechanism 2 is horizontally arranged on the machine On the shelf 1, there is a jig transmission space inside the transmission mechanism 2, and timing belts are arranged on both sides of the transmission space. position; the above-mentioned positioning and supporting mechanism 3 is set at the tearing film station, after the jig 0 moves to the tearing film station, after positioning and supporting mechanism 3 positioning, the glass sheet to be torn off placed in the jig 0 passes through The positioning and supporting mechanism 3 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com