Multilayer concave-convex embossed non-woven fabric and production method thereof

A production method and technology of non-woven fabrics, applied in the directions of lamination, lamination device, layered products, etc., can solve the problems of health impact, lack of comfort, and increased cost of producers and users, and improve the safety of use. , Improve production environmental protection, enhance the effect of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

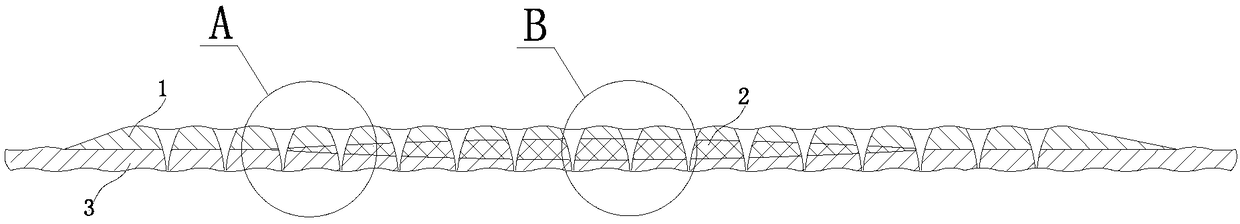

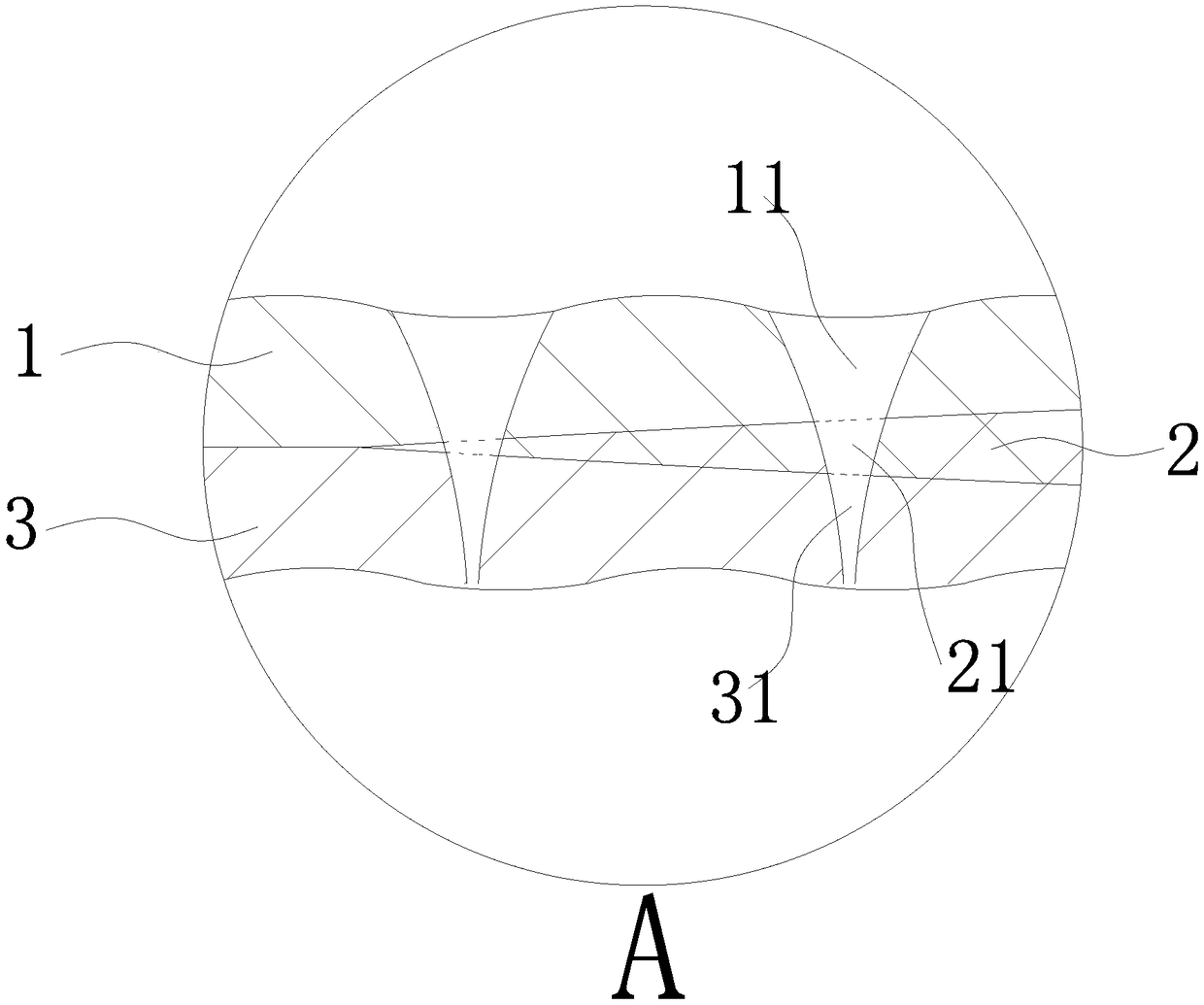

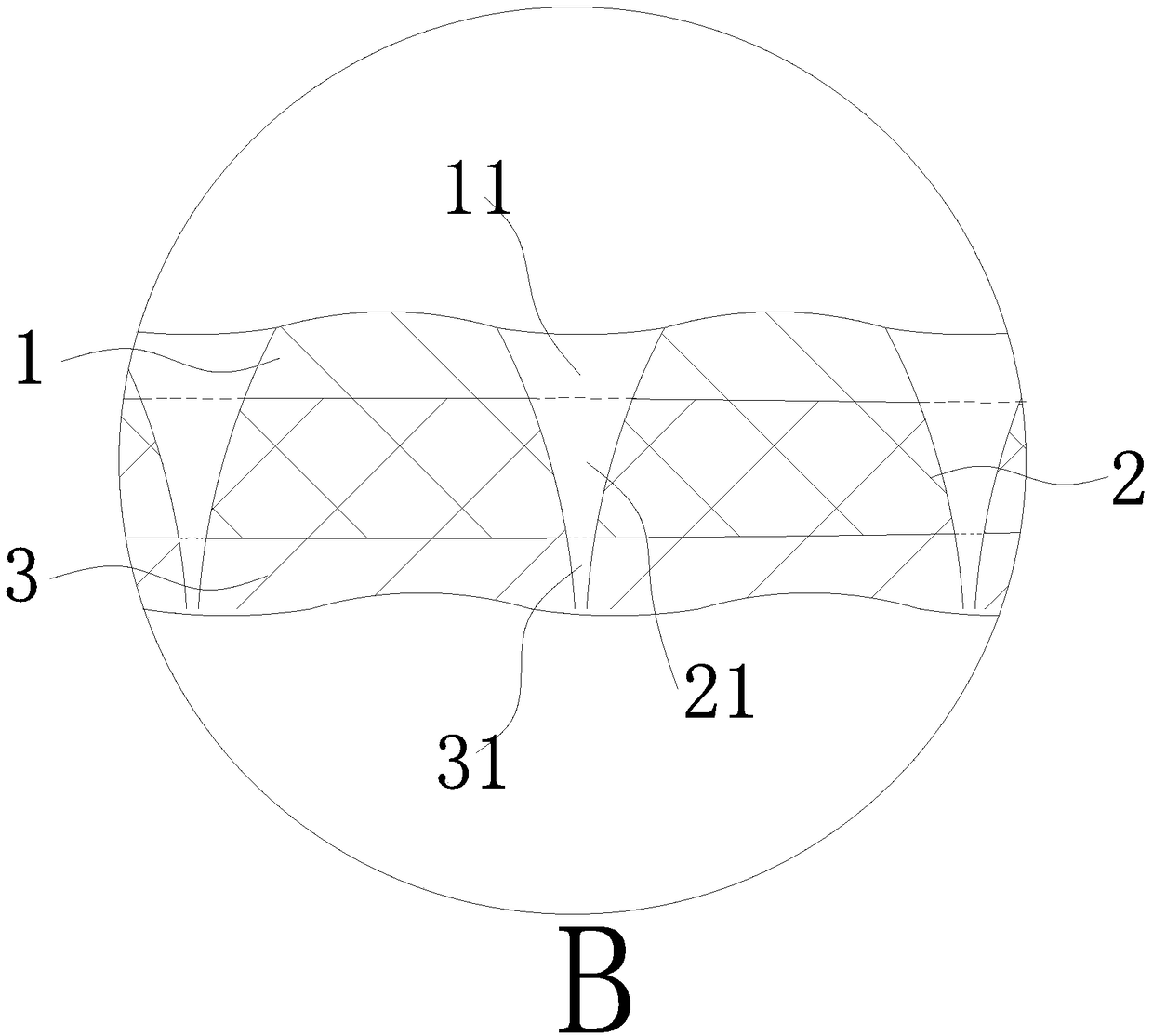

[0034] figure 1 Schematically shows a multi-layer concave-convex embossed nonwoven fabric according to an embodiment of the present invention, including a hydrophobic layer 1, a diversion layer 2 and a hydrophilic layer 3, and the diversion layer 2 is arranged between the hydrophobic layer 1 and the hydrophilic layer. Between the layers 3, the diversion layer 2 is attached to the hydrophilic layer 3, and the hydrophobic layer 1 and the hydrophilic layer 3 are attached by pressing, and the hydrophobic layer 1 is provided with concave-convex shapes.

[0035] In the multi-layer concave-convex embossed non-woven fabric provided by the present invention, the hydrophobic layer 1 of the surface layer has the function of one-way rapid water diversion and hydrophobicity, the concave part is conducive to the sliding and diffusion of liquid, and the convex part is condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com