Vibrating screen equipment for screening building sand

A vibrating screen, sand material technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of uncontrolled screening material area, screen congestion, screening speed reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] as attached figure 1 to attach Figure 10 Shown:

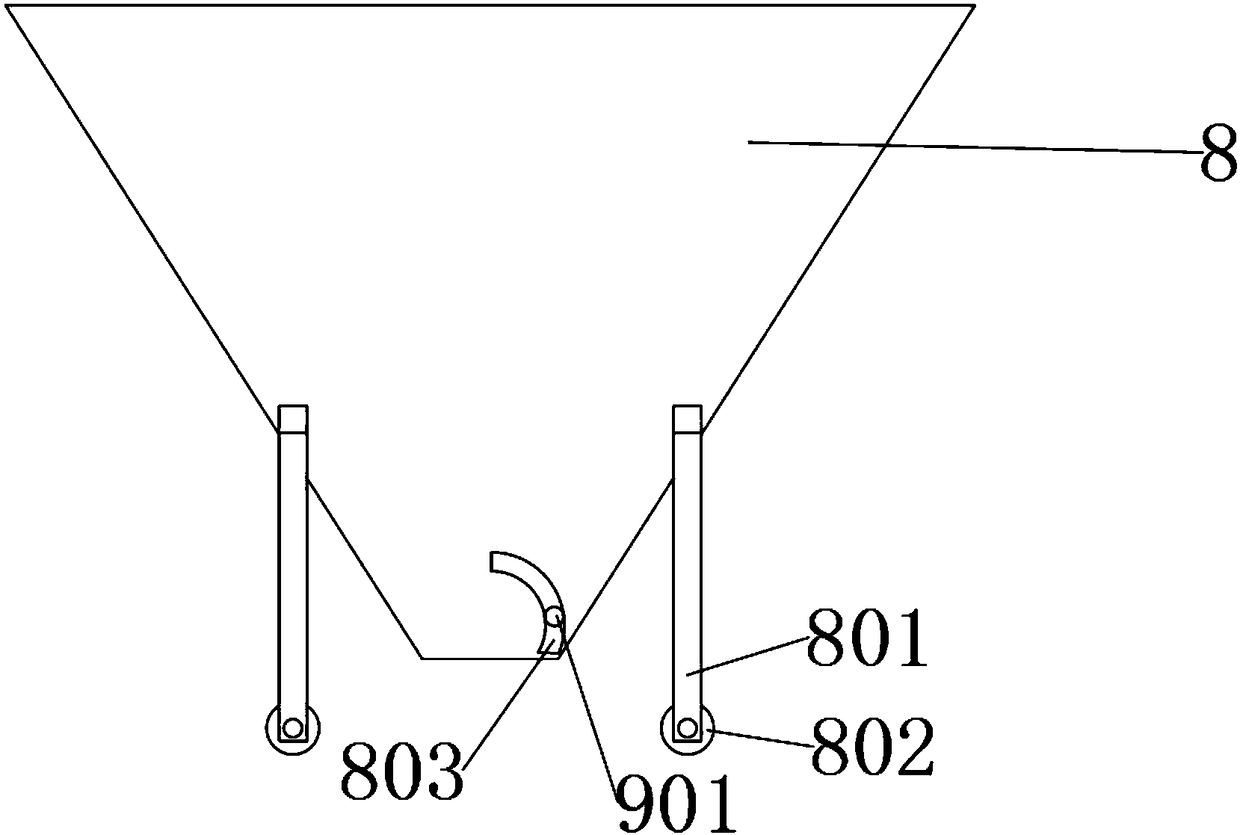

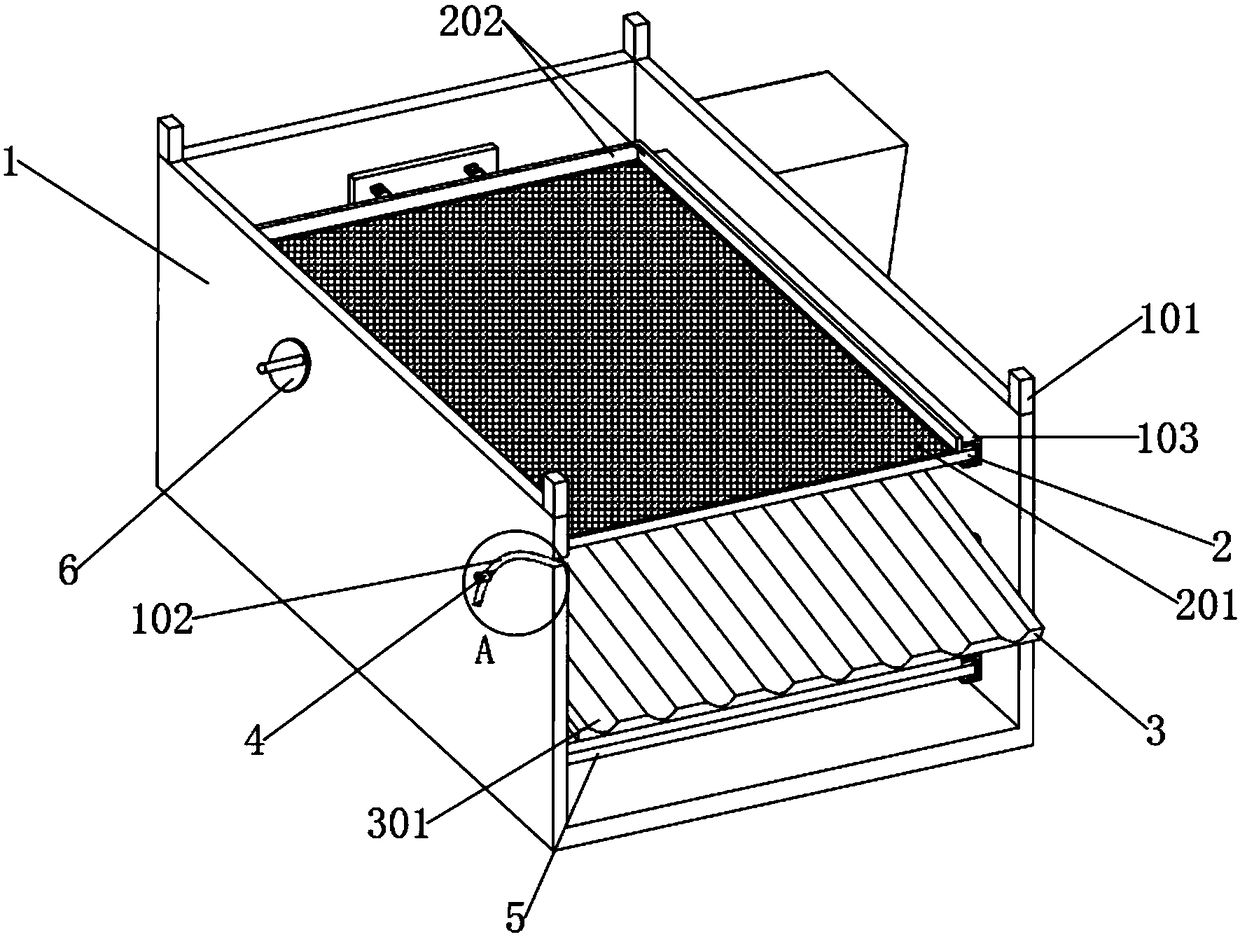

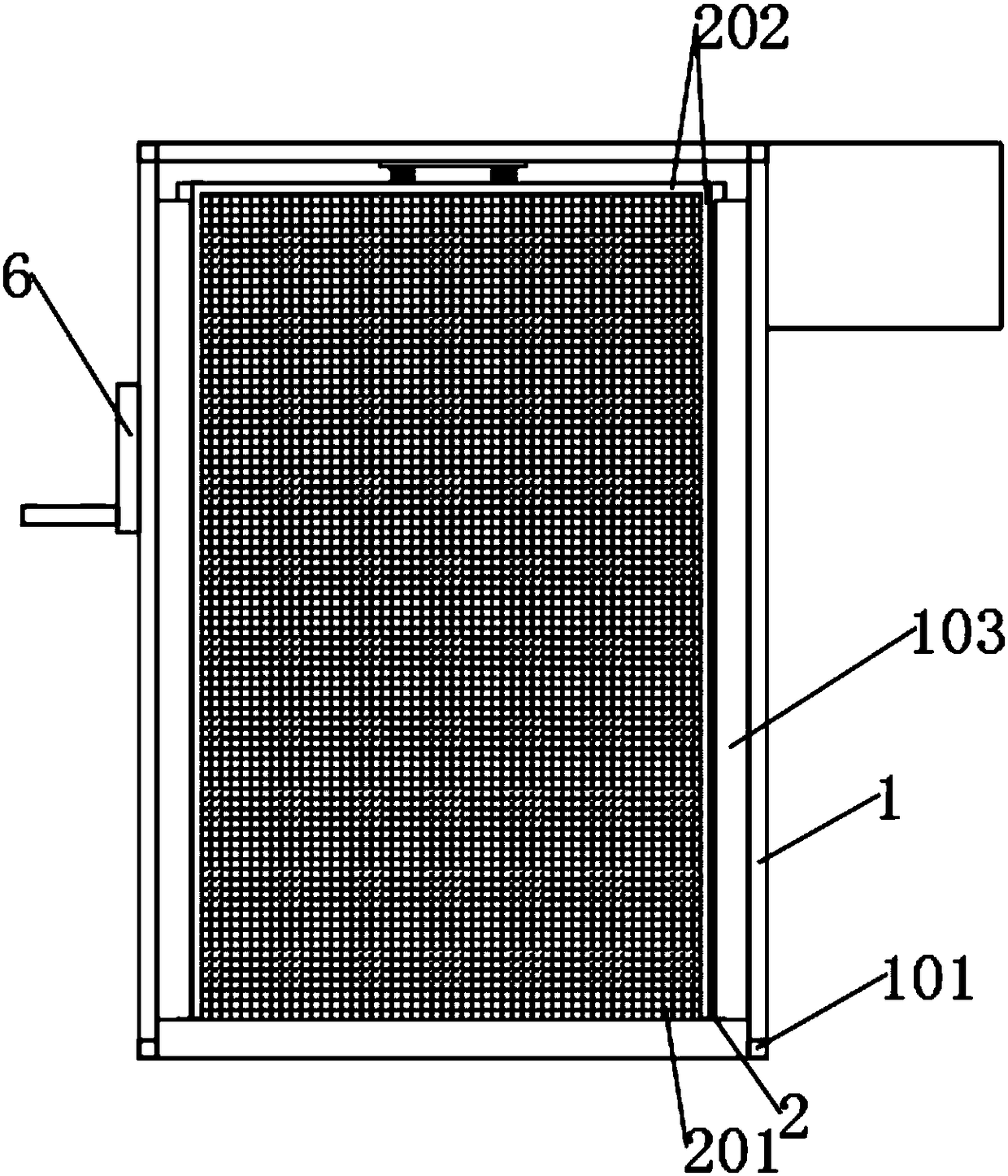

[0038]The present invention provides vibrating screen equipment for screening construction sand, including a main body 1, a stopper 101, a guide groove 102, an auxiliary connector 103, a screen body 2, a screen 201, a baffle 202, a deflector 3, and a deflector Groove 301, rotating rod 302, fixing piece 303, fixing head 4, auxiliary rotating plate 401, sand receiving plate 5, auxiliary supporting wheel 501, hand wheel 6, transmission belt 601, gear 602, supporting member 7, supporting wheel 701, sand storage Bin 8, auxiliary rod 801, connecting wheel 802, arc groove 803, top plate 9, hand crank 901, sand baffle 902 and locking teeth 903; the main body 1 is a rectangular internal hollow structure, and the upper part of the main body 1 is welded The block 101 is installed in the way, and the auxiliary connector 103 is installed on the inner side of the main body 1, and the side of the main body 1 is provided with a guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com