Hole sealing bag and production process thereof

A technology of sealing bags and bag bodies, which is applied in the directions of bags, sacks, and bag making operations, can solve the problems of high packaging workload and difficulty, and easily affects the edge sealing of the bag body. Reduce labor costs and reduce the effect of the sealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention is further described below in conjunction with specific embodiments:

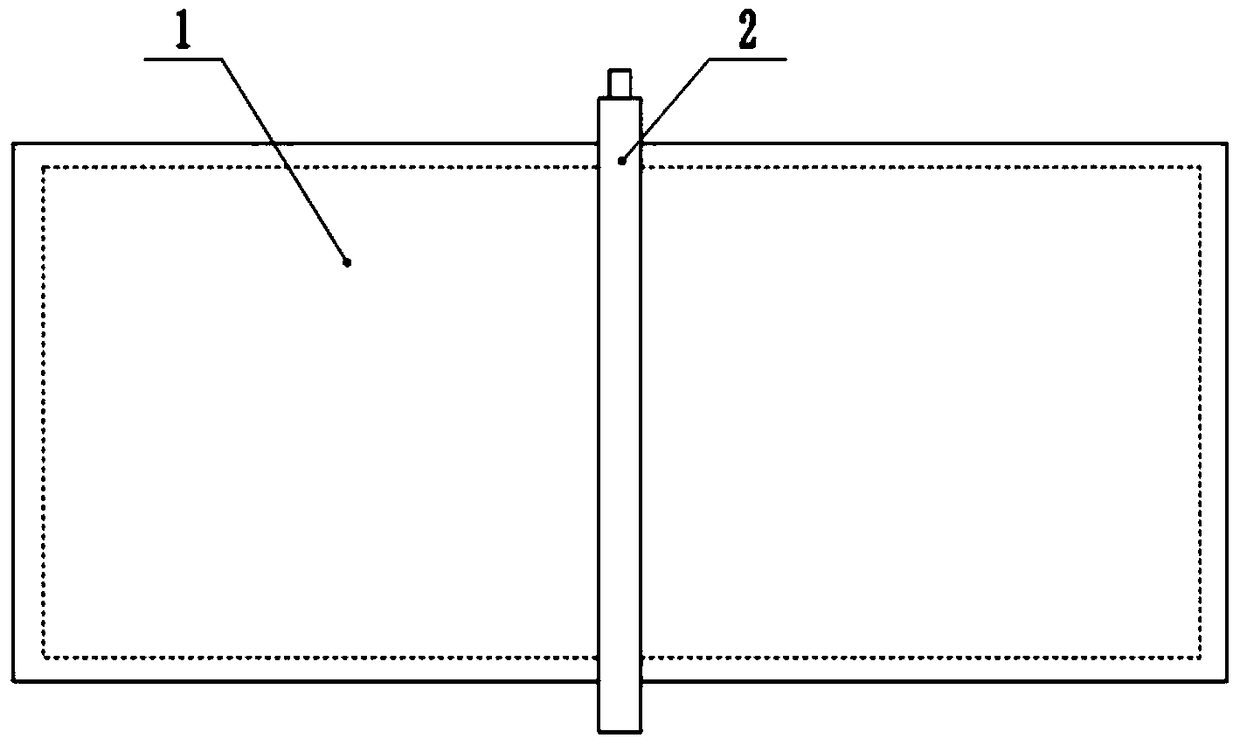

[0021] figure 1 It is a schematic diagram of the structure of a traditional sealing bag. The sealing bag includes a bag body 1 and a spacer strip 2. The spacer strip 2 passes through the middle of the bag body 1 to divide the bag body 1 into two parts that are sealed and independent from each other. The bag body 1 Divided into two independent parts, when the spacer strip 2 is drawn out from the bag body 1, the two mutually independent parts in the bag body 1 communicate, wherein the spacer strip 2 is perforated on the bag body 1 by a conventional method.

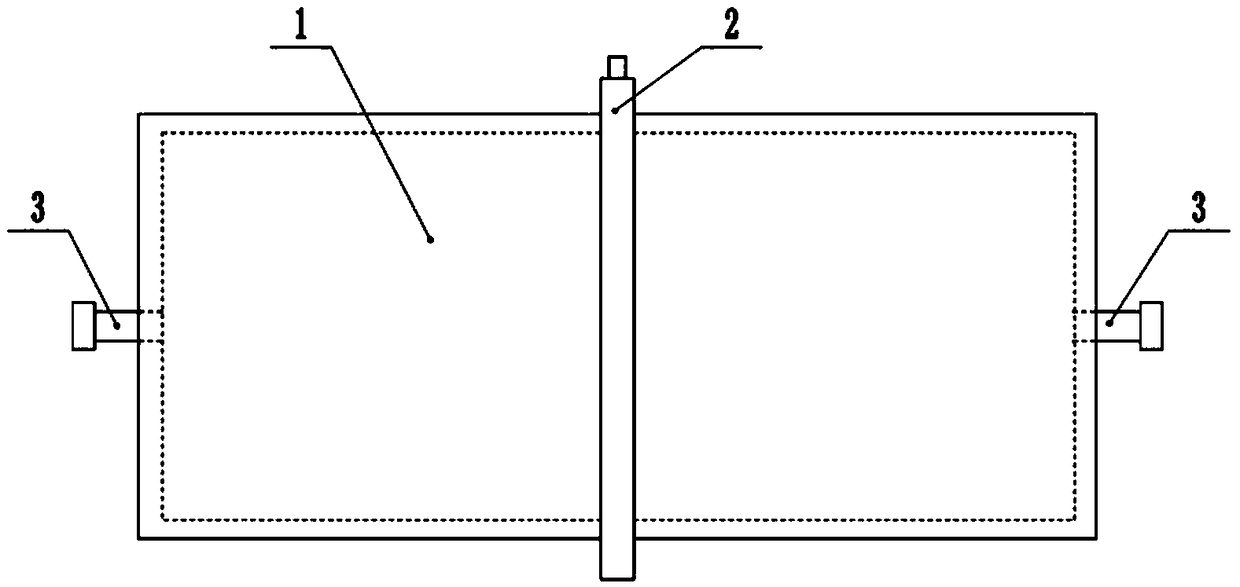

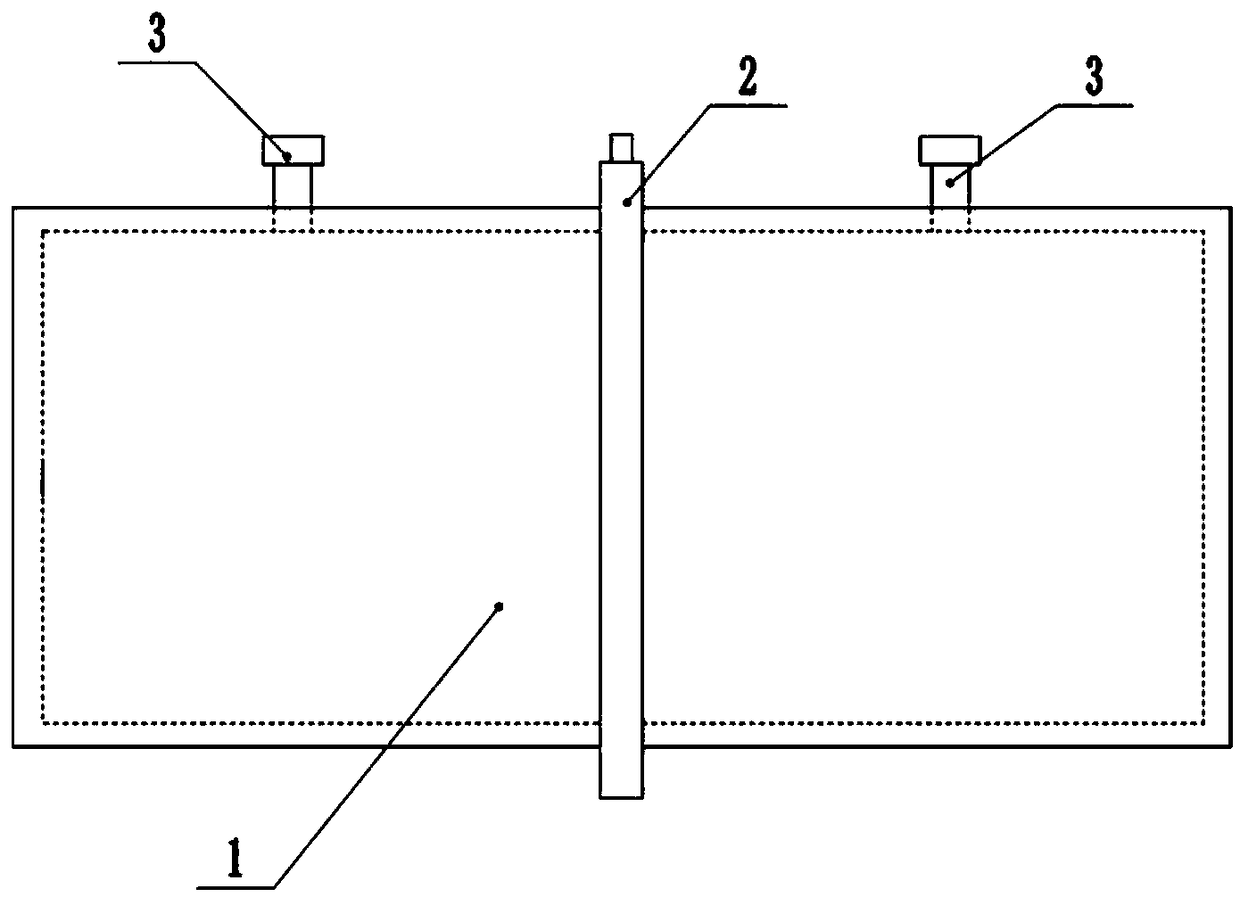

[0022] refer to figure 2 and Figure 4 On the bag body 1, two filling nozzles 3 respectively connected to two independent parts in the bag body 1 are installed, and a detachable sealing cover 4 is installed on the filling nozzle 3. Preferably, the filling nozzle 3 is arranged on the peripheral edge of the bag body 1, and its inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com