Corrugated case printing-adhering production line with high-speed code-spraying function

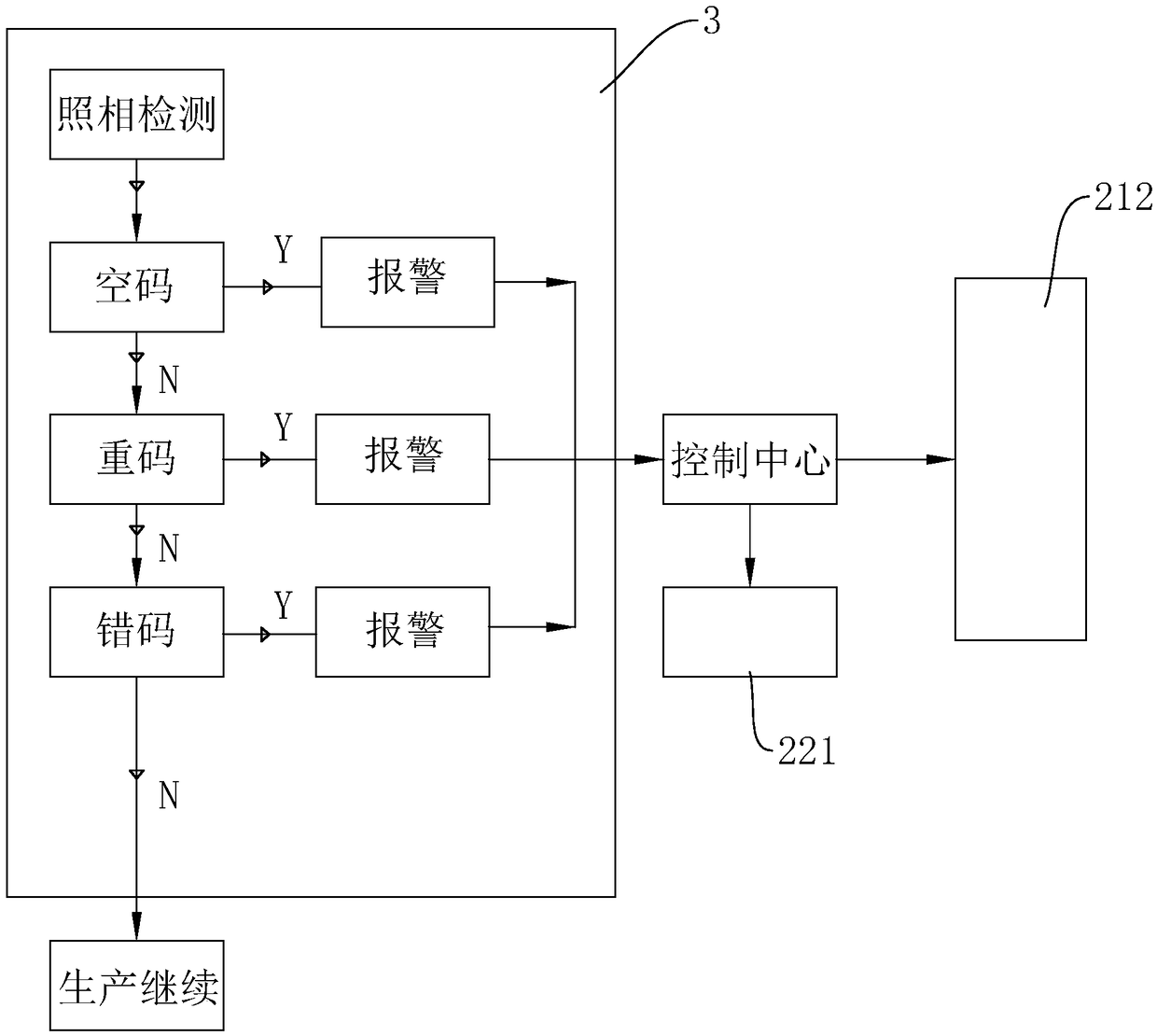

A corrugated box and coding technology, which is applied in the field of corrugated box printing and bonding production line, can solve the problems of reduced production efficiency, order change, power failure, complicated mechanical failure, and entry of defective products, etc., to improve production efficiency and convenience. The effect of checking and sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top "Face", "inner" and "outer" refer to directions toward or away from, respectively, the geometric center of a particular component.

[0042] A corrugated box printing and bonding production line with high-speed coding function, such as figure 1 As shown, it includes the case conveyor belt 1 and the paper feeding part 11, printing part 12, slotting and creasing part 13, die cutting part 14, folding and gluing part 15, and stacking Part 16 and counting and binding part 17.

[0043] Such as figure 1As shown, a code spraying mechanism 151 is installed on the folding and gluing part 15. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com