Novel energy-saving and high-efficiency prefabricated electric heating curing kiln for building components

A building component and assembly technology, which is applied in the field of electric heating and curing kilns for new energy-saving and high-efficiency assembly building components, can solve problems such as low production efficiency, low mold cycle rate, and impact on production capacity, and achieve increased production capacity and high thermal energy utilization. , the effect of not wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

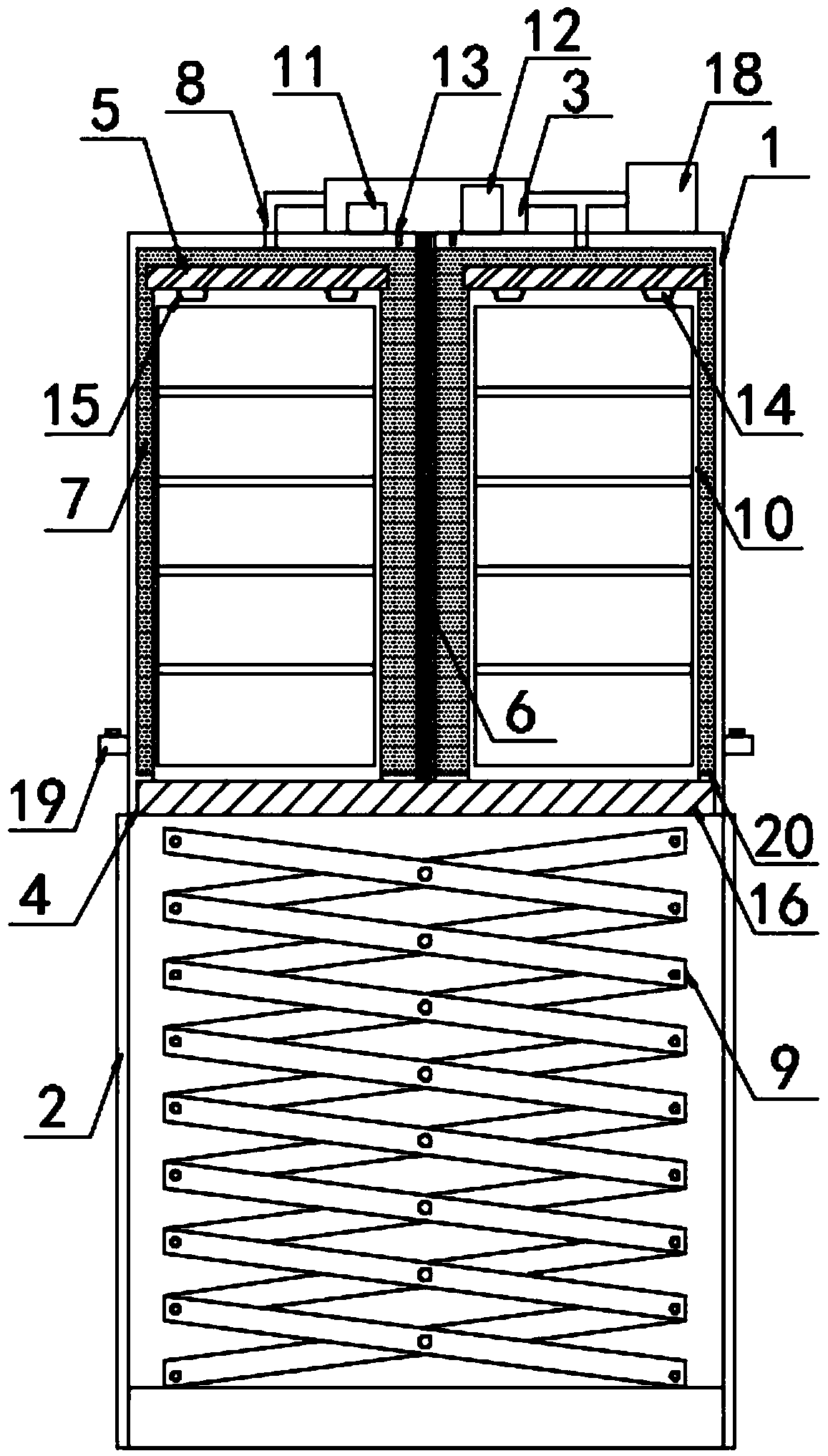

[0025] according to Figure 1-3 A new type of energy-saving and high-efficiency prefabricated building component electric heating curing kiln is shown, including a heating kiln body 1 and a loading frame body 2, the charging frame body 2 is fixedly arranged at the bottom of the heating kiln body 1, and the heating kiln body A control box 3 is provided on the top of the body 1, and a PLC controller 11 and a frequency converter 12 are arranged inside the control box 3, and the frequency converter 12 is arranged on the side of the PLC controller 11, and the top of the inner cavity of the heating kiln body 1 is provided with There is a temperature sensor 13, the temperature sensor 13 and the frequency converter 12 are electrically connected to the PLC controller 11, the model of the temperature sensor 13 is set to WZP-PT100, and the temperature in the heating kiln body 1 is detected by the temperature sensor 13, thereby The signal is sent to the frequency converter 12 through the ...

Embodiment 2

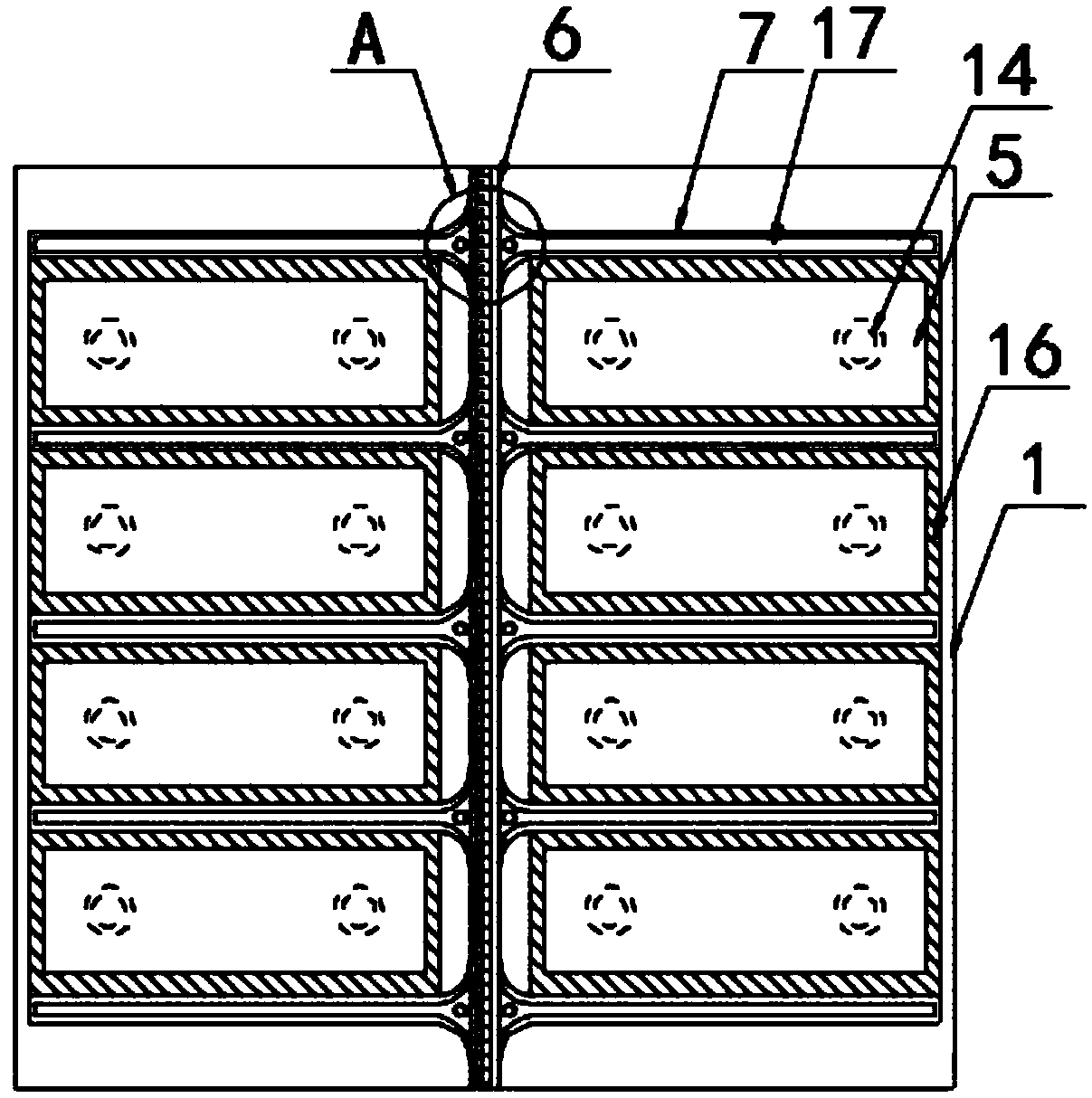

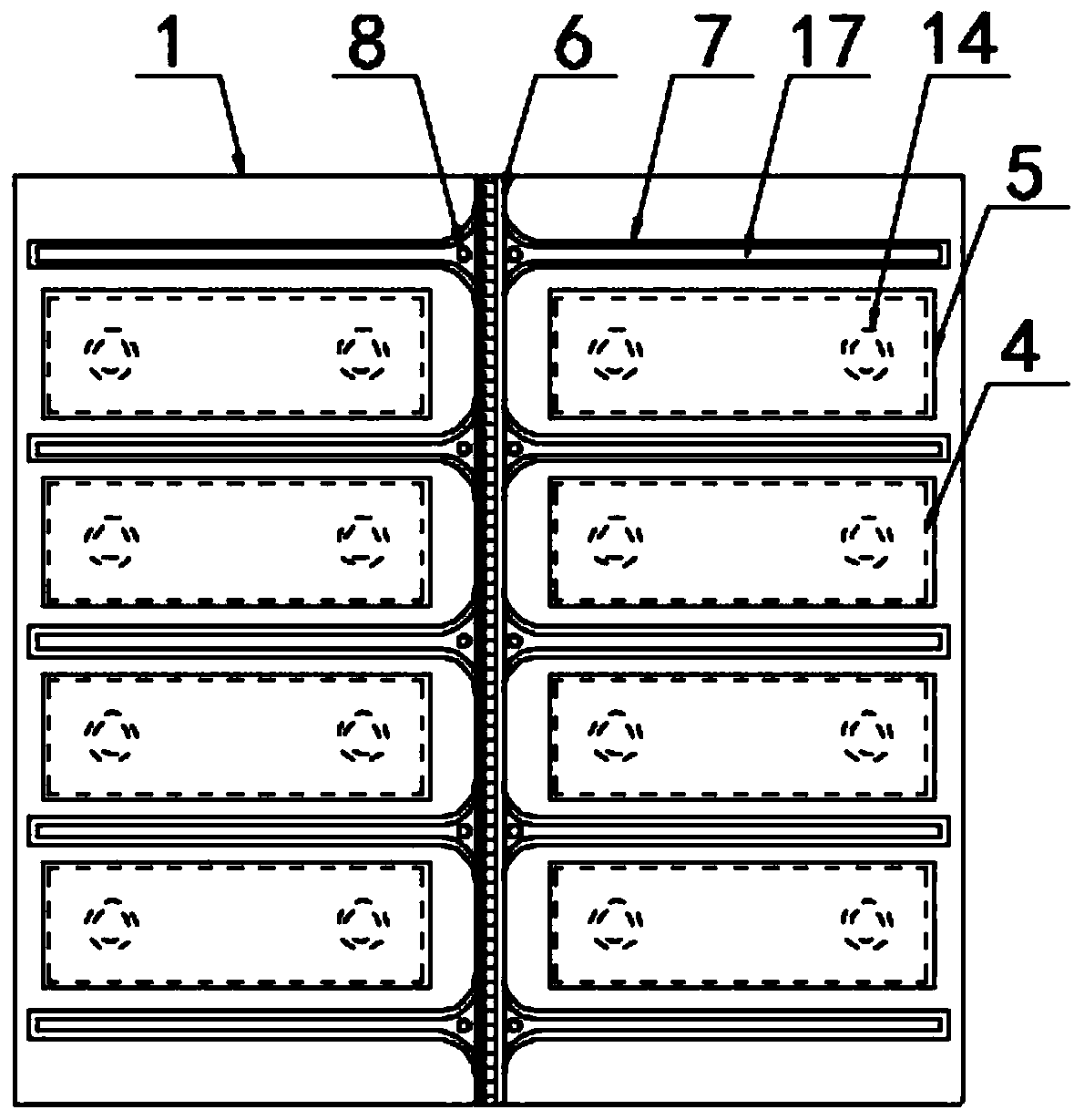

[0028] according to Figure 2-3 In the electric heating and curing kiln of a new type of energy-saving and high-efficiency prefabricated building components, the heat conduction plates 7 and the placement racks 10 are arranged in multiples, and are evenly spaced from front to back, and two adjacent heat conduction plates 7 The distance between them is greater than the width of the placement frame 10, and a plurality of the bottoms of the placement frames 10 are fixedly connected to a support base plate 16, and the two side walls of one end connected to the heat conduction plate 7 and the heating plate 6 are set as curved surfaces, and the heat conduction plate 7 and the The thickness of one end connected to the heating plate 6 is greater than the thickness of the other end, which facilitates a large area of contact with the heating plate 6 and quickly conducts heat to the inside of the heating kiln body 1;

[0029] according to figure 1 with Figure 4 In the electric heati...

Embodiment 3

[0032]Different from Embodiment 1-2, the heating plate 6 in the heating kiln body 1 can be arranged in multiples and be arranged at intervals with each row of placing racks 10 to realize mass production.

[0033] The working principle of the present invention:

[0034] Refer to the attached Figure 1-3 , when in use, the construction components can be placed on the placement frame 10 in the loading rack body 2, the hydraulic lifting platform 9 drives the placement frame 10 to move upward, and the placement frame 10 lifts the top cover plate 5, thereby entering the heating kiln body 1 for heating work, when heating, the inner heating wire 62 in the heating plate 6 performs heating work, and the heat is conducted to the heat conduction plates 7 on both sides through the heating plate 6, thereby heating the building components on the multiple racks 10, heating During the process, the temperature in the heating kiln body 1 is detected by the temperature sensor 13, so that the sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com