Full position pipe-pipe intersecting line automatic welding system and welding method

An automatic welding and intersecting line technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of inconsistent weld quality and affecting normal use, so as to ensure depth consistency, normal use, and quality high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

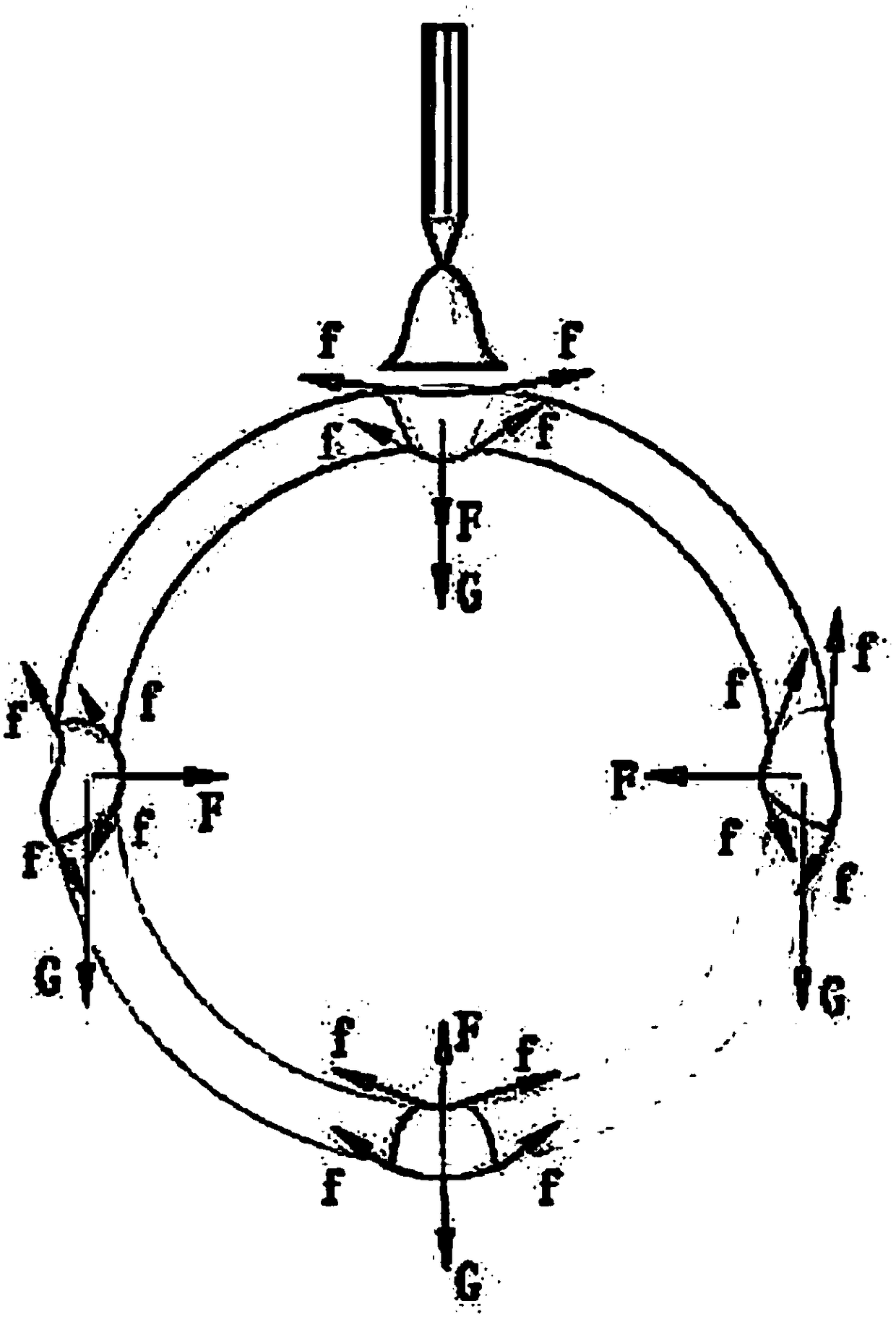

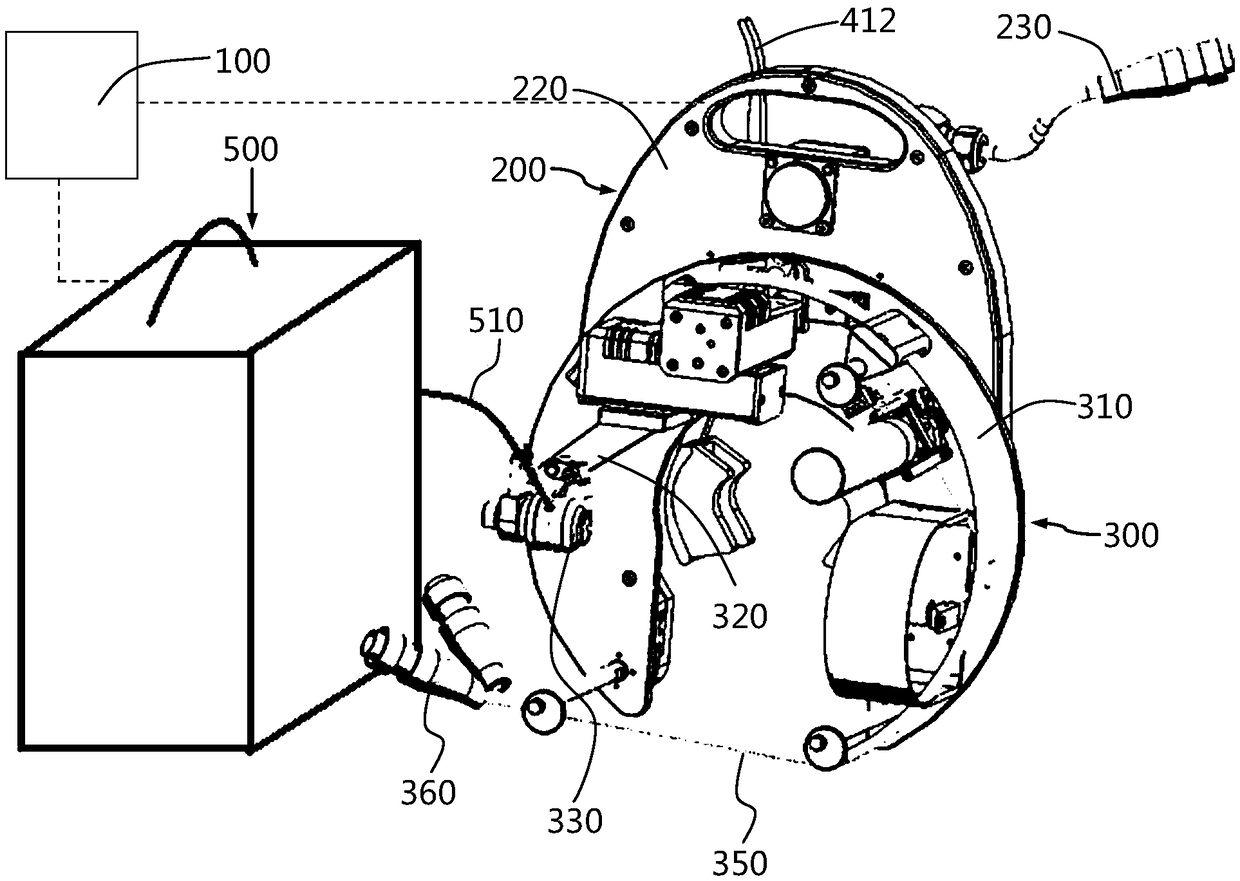

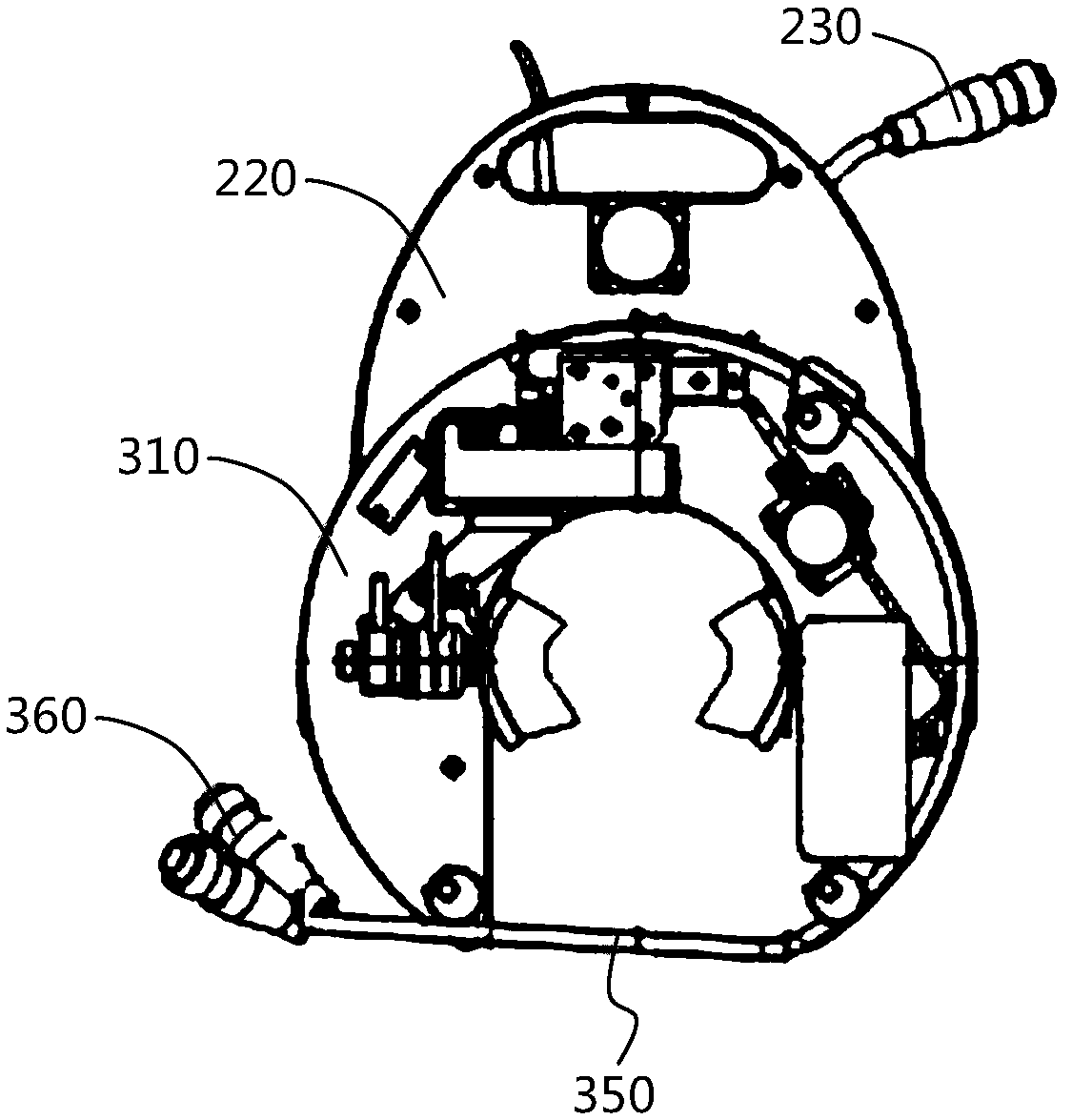

[0057] Such as Figure 2-7 The shown all-position pipe-pipe intersecting line automatic welding system includes: a welding power source 100, which provides a power source for the welding system.

[0058] The welding system is fixed on the outside of the pipeline in the circumferential direction, and to achieve welding in the circumferential direction, it needs to make a circular motion with the center of the pipeline as the center, so the transmission part 200 is required to provide a power source for it. Transmission part 200 comprises a motor-reducer 210, the gear 240 that is connected with reducer and chassis 220, and gear 240 is fixed on the chassis 220, and motor-reducer 210 is electrically connected with welding power source 100; Transmission part 200 also comprises a handle 230, the hand-held handle 230 is fixed on the casing of the motor. When in use, the hand-held handle 230 installs the system on the pipeline, which is convenient and quick to use.

[0059] The rotat...

Embodiment 2

[0066] This embodiment also provides a welding method for an all-position pipe-pipe intersecting line automatic welding system, including the following specific steps:

[0067] S101. Cleaning and requirements before welding: 1) When welding carbon steel pipes, the 8mm of the welding joint should be polished and derusted to expose the original metal color; 2) The cut of the pipe should be flat and vertical, and there should be no gap between the two pipes; 3) Use acetone or alcohol to clean the oil on the surface of the workpiece;

[0068] S102. Open the chuck and set it across the pipeline to be welded, and then the chuck clamps the pipeline under the action of air pressure;

[0069] S103, the intake pipe starts to intake air, the intake volume is controlled at 6L / min, the welding torch is preheated and the wire is fed, the diameter of the welding wire is 1.0mm, and the wire feeding speed is 1500mm / min;

[0070] S104. The motor-reducer works at a rotation speed of 0.15 rpm, d...

Embodiment 3

[0075] This embodiment also provides a welding method for an all-position pipe-pipe intersecting line automatic welding system, including the following specific steps:

[0076] S101. Cleaning and requirements before welding: 1) When welding carbon steel pipes, the 5mm of the welding joint should be polished and derusted to expose the original metal color; 2) The cut of the pipe should be flat and vertical, and there should be no gap between the two pipes; 3) Use acetone or alcohol to clean the oil on the surface of the workpiece;

[0077] S102. Open the chuck and set it across the pipeline to be welded, and then the chuck clamps the pipeline under the action of air pressure;

[0078] S103, the intake pipe starts to intake air, the intake volume is controlled at 8L / min, the welding torch is preheated and the wire is fed, the diameter of the welding wire is 1.0mm, and the wire feeding speed is 1800mm / min;

[0079] S104. The motor-reducer works at a rotation speed of 2.2rpm, dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com